|

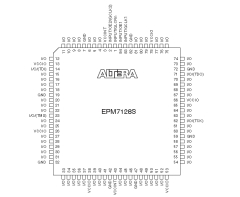

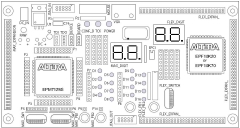

Altera MAX 7000S

- MTXPlus+ Test Bed

|

Dave's Max 7000 Development

Board

|

Hardware Test Bed

Rather than trying to go straight to

development of the glue logic for MTXPlus, I think it is a

better idea to experiment by developing some test programs

that will execute on a simple hardware test device.

Altera produce a

range of "Development" boards, including the DE1 that I use

to run a copy of Andy Key's REMEMOTECH (an emulation of the

Memotech MTX computer running on a Cyclone II FPGA (for

details on the Cyclone II, see this page on the

Altera website), as well as CPLD development boards.

These boards come in a range of prices, but a cheaper option

is to build my own test bed, which will require a bit more

effort but should be able to facilitate testing of logic

designs on real hardware.

To be able to exercise the programmed logic

and display the resultant outputs, a board with basic inputs

and outputs from switches and LEDs will do the job. Here is

my design for Dave's Development System . . . . .

[When I was half way through wiring up my

board, I discovered that Altera had produced EPM7128S based

Development boards for its

University Program - the UP1 and UP2. These boards have

two CPLDs installed, a MAX7128S and the more powerful

FLEX10K20 which has 20,000 gates. As it turns out, these

boards have remarkably similar I/O functions as my board.]

Basic Features :

-

A single board containing and EPM7128S CPLD

with input and output hardware

-

Logic Inputs : 2 x 8 bit DIP switch

packs for logic inputs (16, configurable as normally high or low,

inputs)

-

Logic Outputs : 2 x 7 Segment displays

(DP not used),

3 sets of 8 LEDs (38 total outputs)

-

Unallocated I/O : 6 Channels (wired to a

SIP header socket and available as required)

-

External power, 5VDC

-

JTAG programming port

-

16MHz oscillator wired to clock input (as will be used in MTXPlus), not

required for combinatorial logic

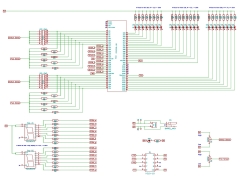

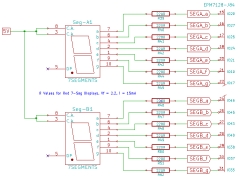

| The basic design was done using KiCad, this

is the schematic drawn before the board was

built.

While building the board, I made a small

modification - each set of DIP switches and

pull-up/down resistor sets can be individually

set high or low as required using separate

jumper blocks. |

|

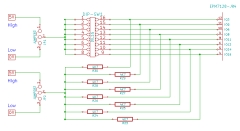

| There are two, 8-bit switch packs for the

simulation of logic inputs. Jumpers allow each

switch pack can be configured to be high or low

when the switch is closed. The CPLD input is

connected via pull/up down resistors to 5v or

0v, this is also selectable by jumper and should

be set to the opposite position from the switch

input selection. |

|

|

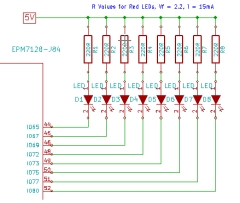

There

are three sets of 8 LEDs for the display of

logic outputs. The LEDs are in three colours,

red, yellow and green, each set has current

limiting resistors with appropriate values for

the LED forward voltage and acceptable

brightness (see below).

|

Colour |

Vf (i=20mA) |

Rc |

Ra |

|

Red |

2.1 |

145 |

220 |

|

Yellow |

2.1 |

145 |

220 |

|

Green |

2.4 |

80 |

130 |

(Vf = Diode forward voltage,

Rc = calculated, Ra =

actual)

|

|

| There are two, 7-segment LED displays (the

decimal point is not connected), these will

allow 2 Hex digits to be displayed on the board

(with suitable VHDL programming inside the CPLD).

The 7-segment displays use red LEDs and have the

same forward voltage as the single LEDs and also

use 220 ohm current limiting resistors. |

|

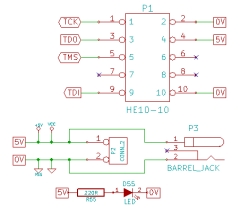

| The CPLD will be programmed on the board,

i.e., using "in system programming" through a

JTAG interface. Power will be supplied from a

standard 2.5mm DC power adapter with an LED to

indicate power is present. (The Altera

Operating

Requirements datasheet advises that 0.2uF

decoupling capacitors should be connected across

each VCC/GND pair, these have not been included

at this point.)

|

|

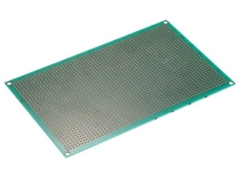

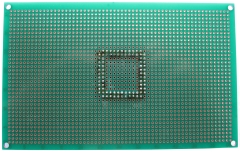

| The development board is based on this type

of prototyping board -

having just plated through holes, rather than

strip-board. The board used is the same size

as the MTXPlus PCBs will be, Eurocard size,

160mm x 100mm. |

|

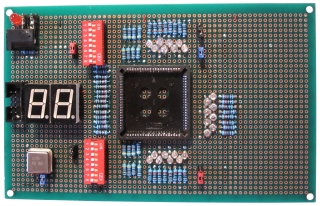

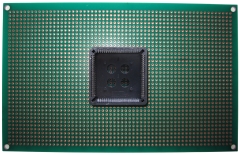

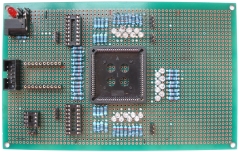

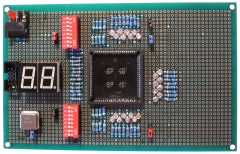

| The form factor of the CPLD that I am using

is for mounting in a PLCC-84, you can see that

the socket takes up a large area of the board -

but significantly less space than would be

required for discrete logic ships performing the

same functions. Placing the CPLD in the centre

of the board allows the most flexibility for

wiring the connections on the base of the

socket. |

|

| Exposing my rather dubious soldering

"skills", the PLCC socket mounted on the

prototype board.

Adjacent pins on a typical DIP IC have a

pitch of 0.1", with pins on the opposite side

separated by 0.3". Adjacent pins on a PLCC

socket are also 0.1", but a second row is also

separated by 0.1". These tightly spaced connections are going to

present a bit of a challenge, but should be

manageable. |

|

| Some time later . . . . . . . . . (OK then,

much, much later)

All non-socketed components mounted, i.e.,

resistors, LEDs, option jumper headers, power and JTAG connectors and the sockets themselves |

|

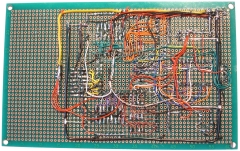

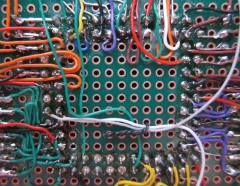

| Solder side of the board, showing my

hopefully functional, but not too pretty,

attempt at wiring it all up. Whilst wiring the

board, I found it easier to reroute a few of the

inputs to different switch positions. I have not

modified the schematic as it has no material

impact on the design - Quartus II makes pin

assignment & reassignment very easy. |

|

| Testing The terminations on the PLCC

socket are tightly packed and many are obscured

as later connections are made. To reduce the

potential need for rework, I did as much testing

during assembly as possible, checking for

continuity, short circuits and correct routing

from the PLCC socket contacts.

At appropriate

stages, I was able to check the I/O - the

switches, LEDs and 7-segment displays. |

|

| Close up of the 84 connection points under the CPLD socket. Production of the development

board has been good practice for building the

MTXPlus CPU board. When I build the CPU board,

rather than connecting the external components

to the PLCC socket in turn, I think that making

all terminations at the PLCC end first will

result in a neater build, even though keeping

track of the wires may be a bit of work! |

|

| Everything but the CPLD installed, "all" that

remains is software testing. |

|

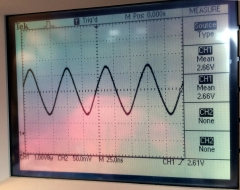

| Although not shown in the original

schematic, the silver can at the bottom left of

the i-phone photo is a 16MHz oscillator - kindly

donated by Martin. Somewhat optimistically, I

hoped that the oscillator output would be a

square wave, however, as you can see from the

'scope trace, it is sinusoidal.

I will either need to condition it on the

board or try doing it in the CPLD. |

|

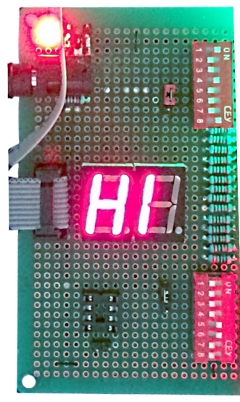

| Success - more or less . . .

Before I built the board, I did a couple of

tests with the LEDs to choose resistor values to give

what I thought to be reasonable levels of

brightness while limiting the current

appropriately.

As it

turns out, the values that I chose results in

the LEDs being a bit too bright - this makes

photographing them a bit of a problem, at

least on my iPhone. On the other hand, should I

want to start running a disco - I already have

the lighting rig!

However, while it's not quite the ubiquitous

"Hello World", at least you get the idea. The

switch packs, LEDs and 7-segment displays all do

what they are supposed to do - which, I have to

confess, was something of a surprise - no errors

with the assembly or programming at the first

attempt!

More to the point, I have been able to test

an early version of the CPU board I/O port decode

logic that I loaded as part of the first test

program - again, this works as expected. |

|

| Design Development - I very

quickly discovered that it would be an advantage

to be able to configure the unallocated I/O on

an "as needed" basis. I have now wired the

unallocated I/O pins to a SIP socket where they

are available for use as required. I don't

imagine that anyone will want to build a board

the same as mine, but for completeness, I need

to do an "as-built" schematic of the board, I'll

get to that shortly. |

<-----

To do |

|

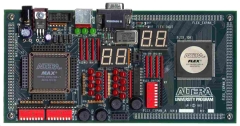

Comparison With Altera

UP1/2 Development Boards |

| Layout of the Altera UP1 and UP2 boards, you

can see that the left hand side of the board has

very similar features to mine, including DIP

switches, LEDs and 2 x 7-segment displays. |

|

| A photo of a UP2 board, obviously looking

far better than mine, but these boards are

obsolete, not readily available and would in any

event, be far more expensive than my version. |

|

MAX7128S Timing <

Previous

Page Goto

Next

Page >

MAX7128S Programming

|