|

"MTX Plus+" -

Diagnostics Card

Early computers such as the DEC PDP 1 (pictured), had

impressive front panels with lots of switches and flashing

lights to control and display the operational status of the

machine. Sadly, modern computers don't feature such interesting

operator interfaces, some might say that they are not required

and would serve no useful purpose in a modern day, or even

1980's vintage, computer, but in my opinion, you can never have

too many flashing lights :-)

I am big fan of flashing lights - useful or not, and

needed to find a good excuse to put lots of lights on MTXPlus.

In the early stages of development, there is likely (hopefully)

to be an operational CPU board before a video board is available

and I want to be able to determine whether the CPU appears

to be running "stand-alone" with no operator interfaces

connected.

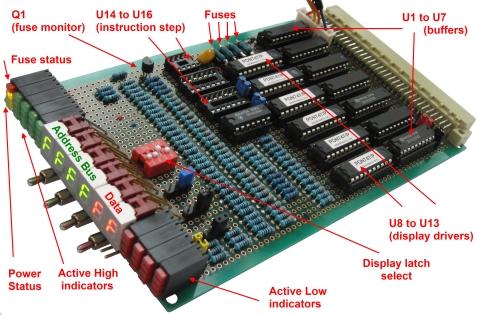

Bus Diagnostic Card

So, killing two birds with one stone, there is now an

MTXPlus Bus Diagnostic Card, although with "slightly" less

functionality than a PDP-1, but then, it is a fraction of the

size and cost!

As you will see, I have gone overboard (again), the board is

much more complicated than it needed to be to just monitor the

status of the MTXPlus bus signals. Martin's board has all of the

required functionality, but is much less complicated - see the

photos at the bottom of the page.

The board uses a number of 7-segment displays and single

LEDs to display the Z80 Address and Data bus status', as well as

the status of the Z80 control bus and miscellaneous MTXPlus

signals. The card also has a reset toggle switch to allow a

hardware reset to be applied to the CPU and other chips with a

RESET input.

In a "late design change", I included a single step

instruction circuit that I had seen on the

Z80 Computer

Project blog. The

Single Step Instruction Circuit page on the blog describes

the purpose of this function and how the circuit works In brief

. . . .

"While debugging you may find you would like to step

through each instruction executed to assure that the

function of your system is correct. Instead of cycling the

clock over and over to get through each instruction with a

single-step clock circuit, a new circuit can be built to

receive a de-bounced button press, and then execute one

instruction at the speed the Z80 is set to run at. This

requires a single-step instruction circuit. To build such a

circuit we will be exploiting two control signals on the

Z80, WAIT

(Pin 24) and

M1 (Pin 27)."

(For a complete explanation, refer to the description on

the

Z80 Computer Project webpage, but I have also captured a

copy on the

notes page.)

|

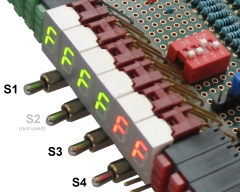

Switches & Jumpers |

|

Switch |

Position |

Description |

|

S1 |

Latch |

Display & Bus Status LEDs Off |

|

Null |

Display & Bus Status LEDs On |

|

Mmnt |

7-Segment manual latch (see

below) |

|

S2 |

(spare) |

Not used |

|

S3 |

Latch |

CPU

in normal (RUN) mode |

|

Null |

CPU

in Instruction Step mode |

|

Mmnt |

Step

Single Instruction |

|

S4 |

Latch |

Not used |

|

Null |

CPU

Reset "normal" position |

|

Mmnt |

CPU

Reset (drives

RESET

low) |

|

Toggle Switches

|

|

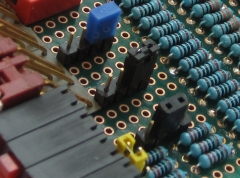

You may have noticed a number of

jumpers in the photos, these were put in to give

me some flexibility should the planned design

have problems, these jumpers turned out not to

be needed, but for completeness, I will explain

their purpose. |

Option Jumpers |

|

I didn't have a SPST toggle

switch to hand when I built the board, so I made

a change to the Instruction Single Step (ISS)

circuit by adding an inverter and doing some minor

wiring changes.

In case this modification did

not work, to give me the flexibility to revert

to the original ISS design without needing to do

potentially awkward wiring changes after the

board was built, these jumpers were included so

that the original design could be implemented by

just adding a new switch.

Now that the SSI circuit has

been tested, they are just left as shown. |

|

|

During the build, I got a little

concerned about the power consumption of the

display elements and the current rating of the

Kynar wire that I was using. The 3 x 3-pin

jumpers were installed to make redistribution of

some of the 5V load easier without substantial

rewiring. Again, this turned out not to be a

problem, so the jumpers are just left as shown.

The yellow jumper allows the

PDN747 blanking input to be controlled by the

display On/Off button, or tied low to have the

7-segment display always on. Again, this is not

actually required and can be in either position. |

|

|

Power Supply |

| Function |

Indicator |

Description |

|

| Fuse Failure |

LED |

Fuse failure on one or more

board +5V lines |

|

| +5V |

LED |

+5V Supply present on backplane |

|

| +12V |

LED |

+12V Supply present on backplane |

|

| +3.3V |

LED |

+3.3V Supply present on

backplane |

|

|

LED Status Indications |

|

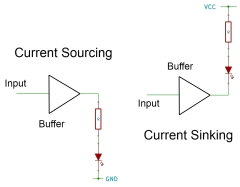

On the diagnostic board, the TTL

signals on the backplane are buffered by

74LS24x buffer/line driver chips before being

used to drive the LEDs and displays.

Due to the way that TTL devices

are constructed, a TTL output can typically

"sink" more current than it can "source", for

example, the National Semiconductor 74LS240/241

datasheet shows that the maximum source current

per output is 15mA, whilst the maximum sink

current in 24mA. Therefore, when driving loads

such as LEDs, the preferred option is to use

current sinking. |

|

In simple terms, in current

sourcing, the current supplied to the load comes

from the chip. In current sinking, the current

supplied to the load comes from

VCC and is merely switched by the

logic chip.

There is a slight issue with

this though, intuitively, we think of something

as being "ON" when at Logic "1". For a

non-inverting buffer, such as the 74LS244 in

current sinking mode, turning on the LED

requires that the input to the buffer is a Logic

"0" to allow the current to flow. Using a

73LS240 (inverting) buffer means that a Logic

"1" on the buffer input becomes a Logic "0" on

the output, allowing current to flow and the LED

to be illuminated. |

|

|

Z80 Control Bus Signals |

| The signals on the

Z80 control bus are active low,

i.e., are normally "1" and are "0"

when in the active state. The

function and operation of these

signals is described in the Zilog

Z80 Databook, you can find a copy in

my Technical Library pages

here. (The Z80

RFSH

signal is used to initiate the

refresh of Dynamic RAM and will not

be used in MTXPlus which uses Static

RAM.)

The status of these active low

signals are indicated by

RED LEDs, when the signal

is active, the corresponding LED

will be ON, when the signal is

inactive, the LED will be OFF.

In this case, the LEDs are

driven by 74LS244 non-inverting

buffers as the LEDs are intended to

be OFF when the signals are

inactive, i.e., at Logic "1". |

|

Z80 Control Signals |

|

BUSRQ |

Bus

Request |

|

|

BUSAK |

Bus

Acknowledge |

|

|

NMI |

Non-maskable

interrupt |

|

|

INT |

Interrupt Request |

|

|

WAIT |

Wait |

|

|

HALT |

Halt |

|

|

RESET |

Reset |

|

|

MREQ |

Memory

Request |

|

|

M1 |

M1 Cycle |

|

|

IORQ |

I/O

Request |

|

|

RD |

Read

Data |

|

|

WR |

Write

Data |

|

|

RFSH |

Memory Refresh (not

used) |

|

| |

To the

Z80 CPU |

|

| |

From the

Z80 CPU |

|

|

|

|

MTX / MTXPlus Specific Bus Signals |

|

VDPINT is the

interrupt signal from the VDP to the

CPU

IEO

is used to prioritise daisy chained

devices that can interrupt the CPU

through the

INT

line. In the MTX computer, the

highest priority daisy-chained

interrupt is from the CTC, the CTC

Interrupt Enable In (IEI)

line is connected to +5V ensuring

that it has the highest priority.

The CTC Interrupt Enable Out

(IEO) line is connected to the DART

IEI line.

The status of these active low

signals is indicated by

RED LEDs in the same way

as the Z80 Control Signals.

The remaining signals are

specific to the MTX/MTXPlus, these

signals are active in the high

(logic "1") state and their status

is indicated by

GREEN

LEDs. |

|

Custom Backplane Signals |

|

VDPINT |

VDP

Interrupt |

|

IEO |

Interrupt

Chain |

|

PHI |

System

Clock |

|

PHI4 |

4

MHz Clock |

|

PHI8 |

8

MHz Clock |

|

SER01 |

Serial

Channel A Clock |

|

SER02 |

Serial

Channel B Clock |

|

P0 |

Page

Port (RAM page select) |

|

P1 |

Page

Port (RAM page select) |

|

P2 |

Page

Port (RAM page select) |

|

P3 |

Page

Port (RAM page select) |

|

R0 |

Page

Port (ROM page select) |

|

R1 |

Page

Port (ROM page select) |

|

R2 |

Page

Port (ROM page select) |

|

RELCPMH |

Page

Port (ROM/RAM mode

select) |

|

|

|

Z80 Address and Data Buses |

|

The simplest method of displaying the status of

the Z80 Address and Data bus signals would be to

have a single LED per signal, in the same way as

for the control signals. Although not really

necessary, I decided that I wanted to decode the

address line and data line signals and present

the actual address and data values on 7-segment

displays.

A single 7-segment display can display the data

for up to 4 binary inputs using 16 hex

characters, 0,1 2, 3, 4, 5, 6, 7, 8, 9, A, b, C,

d, E, F.

The binary inputs must be decoded to determine

which of the 7 segments should be illuminated to

display the character corresponding to the

inputs. |

Image from:

Frederick Blais blog |

|

This was somewhat problematic,

whilst Binary Coded Decimal (BCD) to 7-segment

display drivers are common, Hex to 7-segment are

not. Typically, a ROM or microprocessor based

solution is used to translate the binary inputs

into the appropriate code to be passed to the

7-segment display.

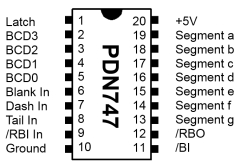

After much searching, I managed

to source this chip, a PDN747, from the US. The

cost of the chips, plus shipping & VAT, as well

as the cost of the 7-segment displays makes it

more expensive and requires a larger footprint

on the board, but I think it's a nice feature. |

|

|

There was a

minor problem with the PDN747 though, the device

needs a latch signal to clock the BCD inputs to

update the displays. The dip switch pack

provides a number of latch selection options:

| 1 |

Latch on the rising

edge of the clock signal (PHI) |

| 2 |

Latch on the rising

edge of

M1 |

| 3 |

Manual latch, using

toggle switch S1 momentary position |

| 4 |

Latch signal from

the backplane (DIAG) |

|

|

|

Power Considerations |

|

The board features quite a

large number of discrete LEDs and 7-segment

displays, potentially resulting in a relatively

high power demand, for example, 35 single LEDs

and 48, 7-segment display elements (6 x 8,

including DPs) , each drawing 20mA would give a

power requirement of some 1.7A, not including the load

from the ICs and pull up/down resistors.

The

backplane

design includes one pair of pins for 5v

power distribution, the DIN connector pins are

rated at 2A, allowing up to 4A of 5v power to be

supplied to each board - adequate for the worst

case load. However, the board interconnections

are made using 30 AWG

Kynar wire, the type that I am using was

advertised as being rated for 0.5A but I believe

that this may be an error, a more typical rating

for Kynar wire is

0.4A, so consideration needs to be

given to how power is distributed around the

board. It would have been ideal to have larger

capacity conductors on the board for the 5v and

ground lines that could form a power bus to

which individual terminations could be made -

kind of like a

ring main, but I didn't think that the size

of the board and component density would make

that very easy.

Instead, I chose to use a number

of radial 5v and ground lines, tied back to

single points at the connector pins and

distribute the power in sections. Given that it

would be possible to overload the conductors, I

installed fuses in each of the power lines.

Ideally, the fuses should have been sized to be

less than the conductor current rating, but I

chose to make them the same, i.e., 400mA.

Although not representative of

the power consumption, the radial power lines

are installed on a board layout basis

| Column |

Components |

Fuse No. |

Fuse Size |

| A |

LS240/LS244 Buffers |

1 |

400 mA |

| B |

PDN747 Display

drivers |

2 |

400 mA |

| C + E |

Misc logic,

7-segment displays |

3 |

400 mA |

| E |

Discrete LEDs |

4 |

400 mA |

The 7-segment displays produce

good brightness levels using a current of ~10mA,

with all segments and the DPs illuminated, this

would require about 480mA, but there will be

some degree of diversity depending on the values

being displayed at a given time. When displaying

values of 0 to Fh the average number

of segments illuminated is ~5, so, assuming that

the numbers being displayed are random, the

current would be ~300mA.

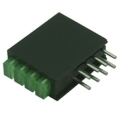

Due to space constraints, the

board uses stacked LEDs that allow 4 LEDs to be

installed in a very small space, there was a

trade-off between the space saving and the

current consumption of the LEDs. The current

required to produce an acceptable level of

brightness is higher than the current required

with a "normal" LED, I found that 16mA produced

an acceptable brightness for each of the colours

being used. The power requirement of the LED

modules will be 35 x 16mA, i.e., 560mA, but

again, some degree of diversity will apply; the

LEDs will only be on when the associated signal

is active, looking at the signals involved, an

on time of 50% would seem to be a reasonable

assumption, leading an estimated current

requirement of ~280mA. (When the bus is not

being driven, the logic inputs will float and

likely drift high. The LEDs turned on by a logic

"1" will illuminate, but as this is only 50% of

the available LEDs, this is not likely to be a

problem either.)

If the current drawn by the

indicators proves to be higher than the fuse

rating, it would be relatively easy to rewire a

couple of the 7-segment displays to take power

from one of the lightly loaded lines feeding the

ICs, but I will leave things as they are unless

it proves to be a problem. |

|

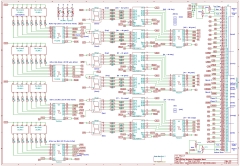

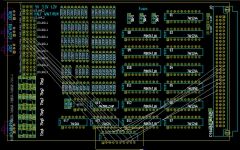

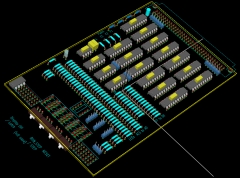

Board Design |

|

This is the "as-built" design of the

diagnostic board, as a result of the 7-segment

displays and associated logic, the board is now

much more complex than I originally envisaged.

(v1.03)

The schematic is drawn with

KiCad, but the prototype (1-off ?) board is

constructed on a eurocard sized prototyping

board. |

|

|

At this stage, the board was not

going to be a PCB, it was constructed on

prototyping board and the "tracks" are wire

links.

Nevertheless, the KiCad layout

and routing tool (PCBnew) was very useful in

optimising the placement of the components. It

was also useful to see the required wiring paths

when moving components around to see if I could

optimise the wiring too. This is an early

version of the layout before I settled on the

final design shown below. |

|

|

The layout for the

diagnostic board, as you can see, the components

all fit on the Eurocard sized board (160mm x

100mm), but there is not a lot of free space and

wiring it up was quite a challenge!

The other challenge was how to make sure that

all of the indicators and switches were

accessible from the end of the board,

particularly if the computer ever makes it into

an enclosure. |

|

|

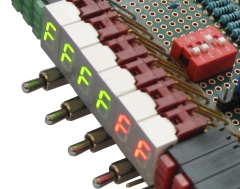

7-segment displays have a much

larger footprint than equivalent single LEDs,

but I was able to minimise that by using 0.3"

displays and making them visible from the end of

the board by using right angled sockets.

The sockets are

Series 800 Vertisockets, manufactured by

Aeries

Electronics, these are quite expensive new

(~£10). I was able to source some "pulls" from

Israel for ~£1.50 - fitted with red displays. |

|

|

There are also around 36 single

LEDs needed for the Z80 control bus signals,

MTXPlus backplane signals and power indicators.

To optimise the available space on the front of

the board, I used 2 x 3mm quad-level LEDs |

|

|

There are also a number of

switches that need to be accessible from the

front of the board.

They are mounted directly below

the display sockets. This was possible since

positioning the sockets to align the displays

with the quad level LEDs left three unused

columns of holes below the socket. |

|

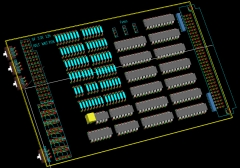

|

A PCBnew 3D view of the

components placed in their locations during the

design phase.

Although I don't have 3D models

for the 7-segment display vertical sockets or

the stacked LED modules that I used, the model

did give a good indication of how the finished

board would look. |

|

|

This image is of the "as-built"

board which includes the various minor

modifications made during the build but does

show that the finished article looks very much

like it was supposed to.

This one also includes the

decoupling capacitors installed inside the

sockets of the ICs - the model is a bit

misleading in that respect - it looks like they

are sat on top of the ICs - obviously, this

isn't the case. |

|

|

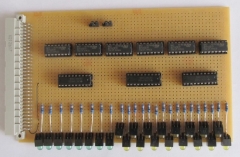

Construction |

|

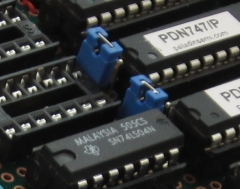

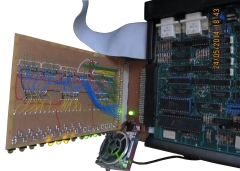

The diagnostic board starting to

take shape, the sockets closest to the DIN 41612

connector are for 74LS240/244 buffers and the

adjacent sockets are for the PDN747, 7-segment

display drivers.

You should be able to make out

the decoupling capacitors installed inside the

DIP sockets to save a little board space. The

layout layout is a little

different to the original layout drawing - I did

some optimisation as I placed the components -

the schematic drawing has been updated to

"as-built". |

|

|

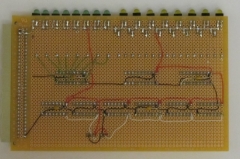

A view of the solder side, with

only the power and ground connections to the DIP

sockets and decoupling capacitors made so far. |

|

|

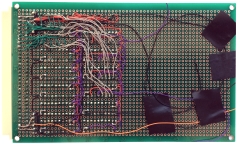

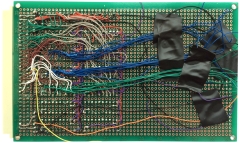

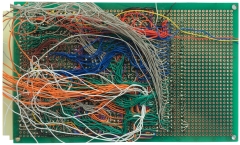

Some progress - the Address

lines (A0-A15) wired up to the LS244 buffers and

onward to the 7-segment display drivers.

The incremental difference in

the photos does not do justice to the effort

required to get to this stage! I am reasonably

confident that the wiring to this point is OK -

at least, checking with a meter, it agrees with

the schematic. |

|

|

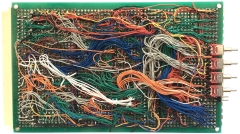

Another update - the blue and

green bundles are the output signals from the

LS240/244 buffers that will control the red and

green LEDs in the quad level LED modules. |

|

|

At around this point, the

hex-to-7-segment display drivers that I had

bought finally arrived from the US and I was

able to test one. Things did not go quite as

well as hoped (you can find the details on the

notes page)

and I need to make a small modification to the

wiring of the PDN747 sockets and add a little

logic to control the update of the 7-segment

displays. In the following

pictures you will also notice that the position

of the single step circuit components and the

orientation of the LED current limiting

resistors is different to the schematic - I made

a number of changes when I added the latch logic

for the PDN747s. |

|

The rest of the sockets mounted;

the top 3 are for the single step instruction

circuit and the one below them is a 74LS04 for the

7-segment latch logic.

The 5 x 10K resistors are

pull-ups for the single step circuit and the 48

x 330R resistors are for the 7-segment displays

(including the decimal points). That "only"

leaves another 36 resistors, the display

elements and switches to be added! |

|

|

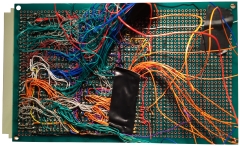

The left hand side of the board

is now almost fully wired.

There is an interesting

dichotomy when doing the wiring, making the

wires as short as possible makes the board look

neater, but would be problematic should any

rework be necessary. I tried to leave a little

slack on most of the connections, but the need

for rework should be minimised as I am testing

the connections at convenient stages. |

|

|

Getting there!

- The obvious difference from

the last photo are the additional column of

resistors for the 4 level LED modules, the 4 x

10K

pull-downs and diodes for the fuse monitor

circuit as well as the capacitors for the single

instruction step circuit. |

|

|

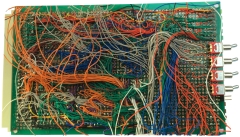

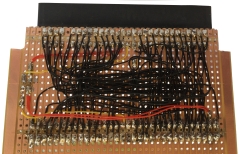

Just for completeness . . . . .

. the solder side of the board.

Still looking a bit of a rat's

nest, but there is some structure to it -

honest! All that remains is to mount the

displays and switches, then connect them up to

the unterminated wires and resistors. |

|

|

The last of the components

mounted, just a hundred or so connections left

to solder now!

The black modules at the left

hand side are the quad level LEDs and the odd

looking right angled sockets are for the

7-segment displays. You can also see the toggle

switches mounted on the underside of the board. |

|

|

To allow the switches to be

mounted in the holes below the display sockets,

the switch contact legs and securing posts were

trimmed so that they were flush with the top

side of the board. This will result in the loss

of some mechanical strength, but I don't think

that is significant here. |

|

|

Completed - ready for testing |

|

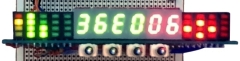

The completed board with all

components, apart from the single instruction

step ICs, installed. The board is being powered

by a temporary supply which provides only 5VDC.

The address and data bytes are

all reading "FF" as the bus signals are floating

and currently "high", i.e., each bit is

currently interpreted as a "1".

The board has been tested and appears to work as

required (after fixing a problem that I had

created when choosing the value used for the

chip enable pin pull-down resistor - more

details on the

notes page). |

|

|

The red LEDs are all off (the

active low signals have floated high) and the

green LEDs (apart from the two spares tied to 0v) are all

on (high). |

|

|

The "final" state of the solder

side of the board, still not looking too neat!

There are a number of spare wires that

are not fully terminated and the slack left in other

wires means that it does not look very tidy, but

it's the best that I could do. I will probably

spend a little more time tying up the wires to

make them a bit more secure though. |

|

|

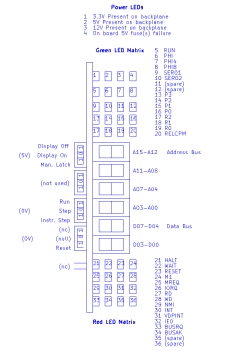

"Crib Card" for my benefit . . .

. .

Showing the position and function of the

various LEDs and switches, it's a poor quality

drawing, being done in KiCad during the

schematic design phase, but it does the job.

I'll probably do a decent drawing at some

point. |

|

|

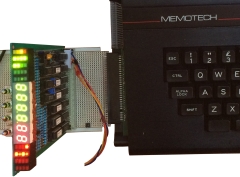

With the single step circuit

components fitted, and after correcting a silly

wiring error, the single instruction step

circuit appears to be working.

This photo was taken with an

MTX512 switched to single step mode, at this

point, the

WAIT,

MREQ,

RD

and INT

signals are all low. Having

looked at the MTX ROM disassembly, Martin was

able to advise that the CPU was stopped in the

middle of the keyboard scanning routine, 36DF

happens to be IN 6 and itís pointing at the 6. |

|

|

A slightly better photo, with

similar results Again, Martin has

advised that the display corresponds to the

start of the keyboard reading routine, 3622 3E

is the first byte of LD A,251 (I

really do need to learn to navigate my way

around the ROM listing) |

|

|

MTX Diagnostic Adapter |

|

Martin built one to help him

diagnose a problem with an ailing MTX and I

thought that it was a good idea to build one

too. The board only patches the signals from the

MTX cartridge port to the MTXPlus backplane

layout. Using the board on a good MTX will help

me get an idea of what the bus signals should

look like for an operating Z80 before I get to

testing the MTXPlus CPU board. |

|

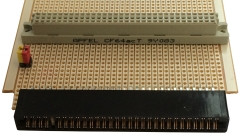

Slightly less impressive than

the diagnostic board - the MTX adapter.

The two jumpers allow me to

isolate the +5V and +12V lines on the MTX bus

from the diagnostic board. |

|

|

The wiring side of the board -

as you can see, the board just cross wires the

terminals from the MTX cartridge port to the

corresponding pins on the MTXPlus bus. |

|

|

A rather blurry photo of the

board running on my original MTX512.

I hadn't fitted the single

instruction step components at this point (they

were on

order), so the 7-segment displays are showing

flickering "8"s as all of the segments are lit

displaying values at high speed. Similarly, the

LEDs are also flickering, but the indications

are consistent with what I expected, but are more

easily seen if I halt the CPU. |

|

Limitations It is

recognised that many of the signals on the bus will

change state at relatively high frequency, even at the

4MHz clock frequency of the MTX computer, many of the

LEDs and the address & data values will rapidly change

state and may only be meaningful when the CPU is in

HALT or

WAIT states. To

mitigate that possibility, I now plan to include a very

low speed clock on the CPU card - in the order of 2Hz -

yes, that is Hertz! At that speed, it should be possible to

make sense of the changing control signals.

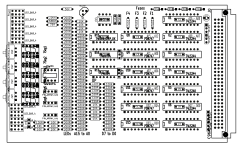

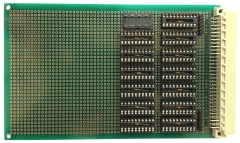

Martin's Diagnostic Board

|

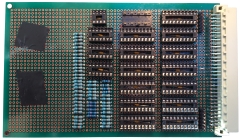

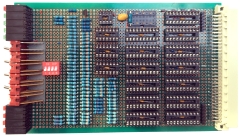

The component layout for

Martin's diagnostic board (prior to wiring)

To reduce the current

consumption, Martin has 6, manually switched

multiplexers, driving the 3 buffers and 24 LEDs. |

|

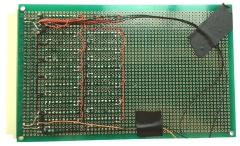

|

A close up view of the LEDs,

which are all visible from the top edge of the

board |

|

|

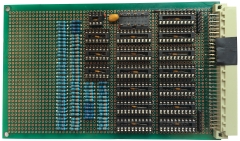

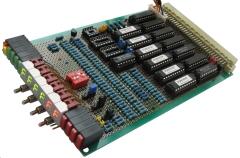

The wiring side of Martin's

board, at a very early stage of construction. |

|

|

Using a simple adapter board,

Martin's MTXPlus diagnostic board connected to a

problematic MTX. |

|

|