|

"MTX Plus+" -

Design Notes

Introduction

When I started out on this adventure, I knew that there were

a lot of holes in my (very limited) knowledge that were going to

need filling if I was to be able to bring the project to a

successful conclusion. I have been doing a lot of reading, but I

have been finding that there are occasions where a few words

from someone "in the know" can explain something that I struggle

to understand from books or web searches. This empirical

knowledge is probably already documented in books and other

websites, but for my own benefit, I have decided to capture

these significant "words of wisdom" on this page for future

reference.

There is likely to be little structure to this page and may

be nothing more than a few disjointed notes, but for what it's

worth - here it is!

| Date |

Topic |

By |

|

27/10/13 |

Trying to understand the function

of the VDP interrupt output (/VDPINT) function used

in the MTX, connected to CTC input 0. |

|

|

28/10/13 |

The Z80 CTC (Counter

Timer Circuit) is an interrupt controller as well as

a four-channel counter or timer.

When /VDPINT goes low at the end

of the last active display line*, the desired action

is to interrupt the Z80 as soon as possible. The CTC

achieves this by decrementing the channel 0

down-counter on the falling edge of its clock input

pin (connected to /VDPINT) and when the down-counter

becomes zero the CTC pulls /INT low and provides the

Z80 with an interrupt vector during the subsequent

interrupt acknowledge cycle.

In order that every VDP interrupt

generates a Z80 interrupt the down-counter is

programmed with the value 1, which is re-loaded into

the counter automatically when it reaches zero. At

the same time the channel 0 output goes high, so is

in effect the inverse of /VDPINT with a short time

lag. This output is not needed for anything, which

is why the pin is unconnected.

Due to pin limitations, channel 3

has no output and could have been used for /VDPINT

but channel 0 was chosen instead as it has the

highest priority.

* In contrast the ZX Spectrum ULA

does not generate an interrupt until the start of

the vertical sync, wasting a considerable time (over

3.5 milliseconds) that could been spent refreshing

the screen "invisibly" and without memory

contention. |

TB |

| |

The

question also generated some useful information on

the functionality of the CTC for use with the RS232

serial ports and the Z80DART

All 4 channels can count 4MHz clock

ticks (timer mode) or their channel specific input

(ch0=VDP, ch1 & 2=4MHz/13, ch3=cassette). Then reach

zero, channel output triggers (ch1/2 feed DART).

This is the reason the clock is divided by 13 by an

IC on the motherboard - so that it can be fed into

the CTC and divided to make all the various baud

rates, to then drive the DART. |

AK |

| 11/11/13 |

Trying to understand Memotech's

modifications to the MTX computer board for the

MTX512S2, i.e., the changes required to support

256KB of memory |

|

| 01/03/13 |

The specification of the original

MTX was a very close match to MSX computers, the

main differences being the Video Display Processor

and the Complex Sound Generator. As the MTXPlus

design develops, there may be an opportunity to add

MSX compatibility too. |

|

| 08/03/14 |

The

original intent was to use a 20MHz Z80 clocked at

full speed, but will now be 16MHz.

Martin identified a potential issue

with having a 20MHz system clock. "At 20 MHz the

cycle time is 50ns, allowing a cycle and a half for

a read/write gives 75ns to play with. Most Flash

Chips are 70ns, as is the RAM in

Lez's kit of

Z80 parts. That doesn’t allow enough time for the

chip select logic. The CPLD needs at least 15ns. At

16 MHz there’s some room to play with. The cycle

time increases to 62 ns, and read/write stretches to

93ns. 15ns for the CPLD leaves 78ns for the memory.

That’s then in theory plenty for 70ns ram and or

flash. 16 MHz might make the clock circuit more

versatile too.?"

Taking Martin's points on board, the

clock speed will now be 16MHz with additional 8MHz

and 4MHz rates. |

MA |

| 19/03/14 |

Giving some further thought as to whether a

degree of MSX compatibility is possible too,

investigating the potential hardware and I/O address

issues, see

this page for the status of my I/O port study. |

DS |

| 08/04/14 |

Mark Kinsey offered some tips on

power supply capacitors which I have taken on board

Also I remember reading that you

intend to use 4.7uF electro's for "bulk" decoupling.

I now use 10uF around boards, and a 100uF right next

to the power input pins, plus another 100uF (or

47uF) at the end of the power traces (the opposite

end to the power input). Always have a 100nF in

parallel with the electro's. |

MK |

| 11/04/14 |

Bus power considerations

The default configuration for the

backplane that I am using provides separate pairs of

power and ground planes, suitable for dual voltage

systems. These planes allow current to be supplied

to the cards in any slot via the pins directly

connected to the power (2 & 31) and ground (1 & 32)

planes. Although it is possible to cut a track on

the backplane and assign one of the ground planes to

a third power rail, the third power rail (+12V) in

MTXPlus has been assigned to pin 17c of the

backplane connector. Although the number of cards

that may require +12V is likely to be very small, to

reduce the potential to overload this trace on the

backplane, power to these pins will be connected by

wire wrapping to pin 17c of the individual slot(s).

The wire that I intend to use has a

maximum current rating of 400mA so this will be the

limiting factor on the 12V supply to each card slot.

It is likely that I will install suitable fuses on

the 12V line for cards that use the 12V supply. |

DS |

| 23/04/2014 |

Diagnostic Board : Single Step

Instruction Circuit In a "late design change", I

included the single step instruction circuit that I

had seen on the

Z80

Computer Project blog. This is a modified

version of the circuit included in Steve Ciarcia's

“Build Your Own Z80 Computer”, I could not find

contact details for the author on the blog page, so

hopefully, he does not mind me posting a copy of the

circuit description here - the original source of

thus information can be found on the

Single Step Instruction Circuit page on the blog.

"While debugging you may find you

would like to step through each instruction executed

to assure that the function of your system is

correct. Instead of cycling the clock over and over

to get through each instruction with a single-step

clock circuit, a new circuit can be built to receive

a de-bounced button press, and then execute one

instruction at the speed the Z80 is set to run at.

This requires a single-step instruction circuit. To

build such a circuit we will be exploiting two

control signals on the Z80, WAIT (Pin 24) and M1

(Pin 27).

M1 is an output control signal

that goes low each time an instruction is fetched.

WAIT is an input control signal that is sampled a

short time after the instruction fetch, and when

activated suspends the operation of the Z80. To

allow only one instruction to execute at a time a

D-flip-flop and one-shot are used. First, two NAND

gates (74LS00) are used to de-bounce a momentary

SPDT push button. The button press signal activates

the D-flip-flop (74LS74) triggering the WAIT line to

become high, and the Z80 to leave the WAIT condition

to run an instruction. After this instruction is run

the one-shot is triggered by the next M1 signal

which is prompted by the instruction fetch. The

one-shot’s output resets the D-flip-flop back which

activates the WAIT signal to pause the Z80′s

operation. The final toggle button adds a NAND gate

and a toggle switch for toggling between an

instruction stepping mode, and standard running

mode. The finished single-step instruction circuit

can be seen below. This circuit is a modified

version of the circuit outlined in Figure 4.5 of

“Build Your Own Z80 Computer” by Steve Ciarcia which

I also display below. Instead of using the 74LS121

as a monostable multivibrator (one-shot) I have

opted to use the 555 timer to cut down on the amount

of different parts needed. Also, I opt for 10K

resistors instead of 4.7K to standardize the

components needed."

Circuit Diagram

(on the Z80 Computer Project blog) |

DS |

| 09/05/14 |

Diagnostic Board : 7-Segment display drivers

The

Paladin Semiconductor PDN747, 7-segment display

drivers have now arrived but initially caused me a

bit of difficulty when I tested one on breadboard. I

could not get any output on the display and the

segment output ports were all stuck at logic "1". I

made a number of attempts to get some technical

support for the chip but Paladin seems to be a tiny

company with inadequate resources - that became

obvious after I placed the order, and despite a

number of promises of imminent shipment, the parts

took almost 7 weeks to arrive.

When I was trying to expedite

shipment of the parts, I discovered that the chip is

actually a custom programmed standard logic chip.

When I could not get any support from Paladin,

I lifted the label on one of the ICs to see if I

could identify the host chip and found that it was

an Atmel PLD, an

ATF16V8.

The Atmel datasheet revealed an

interesting discrepancy with the Paladin datasheet -

pin 11 on the Paladin datasheet is labelled "/BI"

and described as "blanking input". I

interpreted this to mean that this active low

pin would blank the display so had tied it

high for testing. The Atmel datasheet

labels pin 11 as "I9/OE",

in registered mode, pin 11 is output enable, i.e.,

must be low to enable the outputs.

Changing pin 11 from being forced high to being low

"magically" turned on the LEDs.

At this point, I discovered

another problem, the display would only update

following a "0" to "1"

change on pin 1 - the latch input. I had expected

that the latch would be required to "freeze" the

display, but when not set, the display would reflect

the status of the inputs. Again, the Atmel datasheet

proved useful, in registered mode, pin 1 is the

clock input and I will need to implement additional

logic to control update to the 7-segment displays. |

DS |

| 24/05/14

Updated

06/12/14 |

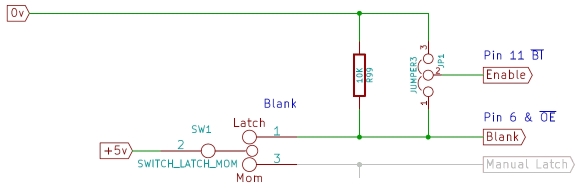

Diagnostic Board : 7-Segment display

latch input I have implemented a

number of options to trigger the 7-segment display

driver latches, selectable by the DIP switches

behind the displays :-

- System Clock (PHI)

- M1 - suggested by Martin.

"Could you drive the address latches with M1,

looking at the Z80 user manual It’s low during

the first 2 cycles of the opcode fetch, your

address indicators would then follow the program

counter, but ignore address bus changes involved

with load store. It also goes low on an

interrupt acknowledge cycle too, but then would

get re-activated on the next instruction fetch

anyway.

- Manually - mainly for initial

testing, but the display blanking switch also

has a momentary position, I use that to pulse

the display latches

- Logic driven signal from the

backplane (DIAG). During testing of the CPU

board, it was useful to have the CPU board CPLD

drive the latch for the 7-segment displays.

Although this could have been achieved using a

patch wire between the two boards, it does

provide additional flexibility for triggering

the displays, so it has now been added as a

backplane signal.

|

DS |

| 26/05/14 |

Diagnostic Board : Display blanking

circuit (TTL pull-down problem)

Whilst testing the diagnostic board, I came across a

very troublesome problem - with more than one or two

buffer chips installed, the enable lines for the

buffers and display drivers were sitting at 1.4V -

the range for TTL 0 volt rails is 0 to 0.8 volts so

the enable pins were being interpreted as being

high, disabling the buffer outputs and blanking the

LEDs.

To anyone who knows what they are

doing, the problem may have been obvious, but it was

not to me. I initially suspected that I had a bad

joint or partial short circuit somewhere, so I spent

a lot of time rechecking the connections and looking

for shorts.

In fact, the problem was not due

to bad construction, but bad design! When I decided

to implement display blanking, I wanted to be able

to set the enable pins for the buffers and display

drivers high using a toggle switch, or to be pulled

low by default. I thought that the easiest way was

to daisy chain all of the enable inputs together and

switch them in one.

This is the relevant section from

the diagnostic board schematic, the "BLANK" signal

is connected to pin 6 of the PDN747 display drivers

and pins 1 & 19 of the 74LS24x buffers, the display

drivers are CMOS devices and the buffers are TTL.

I wanted to minimise

the power consumption and so wanted a "weak

pull-down", i.e., to use a high value resistor. What

I had failed to realise is that TTL inputs are

actually current sinking, an LS TTL input needs to

be able to sink 0.4mA to be interpreted as a logic

low. The voltage drop across a pull down resistor

needs to be no more than 0.8 volts to meet the TTL

specification of 0 to 0.8 volts for a low level. (CMOS

devices can operate with much higher pull resistor

values and were not a problem here). Pull up

resistors are less of an issue due to the wider

margin of voltage levels for a high input signal of

2 to 5v.

So, for the 74LS24x buffers,

as each has two enable pins, there are 14 TTL inputs

that need to sink current to 0v, using Ohms law :

| R = V

/ I |

where |

V = a maximum of 0.8

volts |

|

| |

|

I = total current, 14

* 0.4, or 5.6 mA |

|

|

Rmax |

= |

0.8 / 5.6 e-3 |

|

| |

= |

143 ohms |

|

This is significantly less than

the 10k resistor that I had used and also the 4.7k

value frequently used for pull-ups. Using the

formula above, it can be seen that a single LS TTL

gate would could be pulled to 0.8V with a 2k resistor,

but my 10k for 14 (or more) inputs was well wide of

the mark. When I was looking for a suitable

replacement value for the resistor, I was initially

worried about the power requirement, so, I tried

reducing the 10k value by "trial and error" to find

a suitable value that would draw the minimum amount

of current and found that a 1.3k resistor seemed to

work.

Update : When I built an adapter

to allow the board to be used with a standard MTX, I

found that the elevated voltage on the enable pins

caused some problems, including the displays failing

to recover from being blanked, so I decided to

replace the pull-down with the correct value. The

closest standard resistor value less than 143 ohms

is a 130R which would result in "wasted" power of

about 38mA but this is fed from the 5v line that

only powers the display drivers, but not the

displays themselves, so that will not be a problem.

It does illustrate why TTL pull-downs are not

recommended - they use a lot of power.

After replacing the resistor, the

intermittent display problems etc. went away.. |

DS |

| 07/06/14 |

CPU Board -

Real Time Clock

The kit of parts

that we received from Lez included a Dallas

DS12887 RTC, this is a "drop–in" replacement for

the IBM AT computer clock / calendar, it is

compatible with the Motorola

MC146818B used by IBM and the compatible Dallas

DS1287. The DS12887 self–contained subsystem and

includes lithium battery, quartz crystal, support

circuitry and an expanded area of 114 bytes of

general purpose non-volatile static RAM (NVSRAM).

There are not many examples on the

web of the use of this RTC on a Z80, but I did find

this really

helpful article written by a Wilf Rigter around

1996. The article demonstrates the use of the DS1287

with a ZX81 and included examples of Z80 assembler

and BASIC programs to access the chip.

Martin was able to use this

information with the DS12887 and modified address

decode logic to make a working RTC that will be

included on the MTXPlus+ CPU board.

Martin has posted the details on the

Memotech forum in this thread |

DS/MA |

| 14/06/14 |

Video Board

- Video Output

With the Yamaha V99x8 being used in the later models

in the MSX range (MSX 2, 2+ and Turbo R), there are

copies of OEM service manuals available on the web

that show how the VDP was implemented. As you would

expect, the input side of the circuits are pretty

consistent, i.e., the CPU interface, clock

generation and VRAM interface.

However, there is much more

variation on how the RGB outputs were conditioned

for the TV/monitor, some designs used transistor

circuits to amplify the RGB outputs and other

systems used a Sony

CXA1145 RGB Encoder

to generate a composite

and/or component output as well as the RGB. The Sony

chip is obsolete and the only datasheet that I can

find has very little English in it, the

ES71145 is functionally equivalent and has an

English datasheet available.

It appears that just about every

MSX manufacturer had a different implementation of

the video output circuitry, particularly when using

the CXA1145 where the values used to implement the

required band-pass filter varied widely.

The easiest solution to implement

appears to be an RGB only output, but I would also

like to have a composite video output available. To

allow the video board to support two versions of the

video output circuit, the board will have pin

headers to allow an appropriate daughter board to be

connected - very much like the design of the

original MTX video board. The daughter board will

also provide other headers for the TV/monitor audio

and video output options. We felt that using a header rather than

mounting the SCART socket or other connectors

directly on the video or daughter board would put

less strain on the board and provide more

flexibility in use.

The other advantage of having the

output components on a daughter board allows us to

design and build the base video board while we

finalise the output configuration and should enable

easier "tuning" of the output side of the video

board if required.

Some comments on the CXA1145 on

this (non-MTX) thread |

|

| 21/06/14 |

Video Board

- Video Output Update Still

struggling somewhat to find a suitable circuit

design for the output side of the video board, I

came across the

GR8BIT project. GR8BIT is a Z80 based hardware

and software project, supplied as a self-assembly

kit, based on an ATX type motherboard and a bus

architecture, with additional boards providing, CPU,

Memory, Video functions etc. that plug into the

system bus. (full

specifications).

GR8BIT is capable of running MSX2

software and uses a Yamaha V9938. I was very

interested in how GR8BIT had implemented the V9938

design and contacted the designer, Eugeny Brychkov.

Eugeny was very helpful, pointing me to the video

board design on the Yamaha YIS503 MSX2 machine and

also the

GR8BIT Knowledge Base article on adding

Composite and S-Video output (KB0014).

In addition to the RGB output, I

intended to include a component or composite video

output and, being in the UK, I had planned on making

the output meet the

PAL

standard rather than

NTSC.

However, during our discussion, Eugeny pointed out

that most modern TVs can accept both PAL and NTSC

signals. The VDP has an NTSC compatible clock output

available (3.58 MHz) but a PAL sub-carrier clock

(4.43 MHz) would require an external crystal

oscillator and associated circuit. To make things

easier, the video output from MTXPlus+ will now be

NTSC, this may give problems with older TV's, but a

PAL compatible output could be added later if

required. Other learning's

for this week include a better understanding of the

differences between the VDP composite sync pin

between the V9938 and V9958. On the V9938. the CSYNC

line on Pin 6 is a tri-level logic I/O pin : High

for composite sync output and Low for VSYNC input.

To use the CSYNC output with a V9938, the tri-level

logic signal has to be converted to a 2-state

signal. This is not required on the V9958 where Pin

6 is composite sync output only, this helps explains

the differences between the CSYNC circuits between

the MSX machines using the different processors. |

DS/EB |

| 24/06/14 |

Video Board

- Video Output Update 2

Although the

V9958 will run V9938 software, the are some minor

hardware differences between the two VDPs which

means that some parts of the V9938 VDP output

circuit design need to be modified to work on the

V9958, for example, the CSYNC signal described

above. Notwithstanding Eugeny's help with the V9938

circuit, I continued to look for examples of

implementations of the V9958 by MSX manufacturers.

Having been used in various

MSX2

machines, there are quite a few, albeit different,

designs using the V9938. The V9958 were used in a

smaller range of

MSX 2+

machines manufactured by Panasonic (FS-A1FX,

FS-A1WSX, FS-A1WX), Sanyo (WAVY PHC-70FD, WAVY

PHC-70FD2, WAVY PHC-35J) and Sony (HB-F1XDJ, HB-F1XV

), the last machines in the MSX range were the

Turbo

R computers, only manufactured by Panasonic as

models FS-A1ST and FS-A1GT. MSX 2+ and Turbo R

machines were only produced for the Japanese market,

so the few circuit diagrams that are available are

in the Japanese MSX service manuals.

I have not been able to locate

service manuals or schematics for any of the Sanyo

or Sony MSX2+ machines, but Hans Otten's

MSX Info Pages has copies of the Panasonic

FS-A1FX circuit diagrams and the full service

manuals for the FS-A1ST and FS-A1GT. These circuit

diagrams will form the basis of the "digital" video

card daughter board, using a slightly more modern

version of the Sony CXA1145P, the

CXA1645P to output

RGB, Composite and S-Video. As Martin is

uncomfortable using the very old Sony parts, the

"analogue" daughter board will be based on the

MSX2/V9938 design, using transistors to amplify the VDP RGB outputs.

|

DS |

| 04/09/14 |

Video Board - "Lesson Learned" about Tantalum

Bead Capacitors ! Write up to

follow - quick version - don't get the polarity

wrong :-)

See this video to get the idea though

|

DS |

| 03/10/14 |

Video Board

- Minor hold up in testing With the

Video board built and the Daughter Board fitted, I

had a bit of a setback. I was unable to get a

picture from the V9958, and even worse, with the

Video board connected, the MTX now had problems - it

would boot OK, but had various issues, including

corrupted display, random freezes and crashes to

PANEL.

Removing the DB and all of the ICs

on the video board, the problem was seen to occur

once the GAL was installed. I initially suspected

that I had created the problem by breaking or

shorting a connection on the wire side of the board

as I messed with the DB. Having retested the board

with a meter and not finding any faults, I tried

disconnecting the pins of the GAL (using an

interposing spare socket between the socket on the

board and the GAL and bending the legs out of the

way) in groups, starting with the outputs then the

Z80 control signals. To my surprise, I found that

the problem was being caused by the /M1 line,

although the GAL verified correctly on the

programmer, it caused the problems described.

Replacing the GAL has fixed the problem. |

DS |

| 30/10/14 |

Video Board

- SCART Connection

| Martin got to the stage of testing

the video board SCART outputs before I

did and found that the composite video

output was not working when connected

via the SCART connector.

We were not

aware that SCART cables have cross-overs

in the connections for audio and

composite video. Making the cross-over

between pins 19 and 20 in the SCART

connection allowed the composite video

signal to be displayed on the TV. |

|

| |

Image downloaded from

leadsdirec.co.uk |

|

MA |

| 15/11/14 |

CPU

Board - Processor Issues

Once

again, Martin got to testing the CPU board before I

did and found that he could not get the Z84C0020PEC

CPU to work above 10MHz. Having tried a second CPU

and having been able to run a known good 10MHz chip

reliably at over 20MHz, we suspected that the

"20MHz" were not what they purported to be.

I have made a few

notes on counterfeit

chips on a separate page, but in summary, based

on some limited testing and close inspection of the

chips, we believe that the "Z84C0020PEC" CPUs are

actually remarked Z80H (8 MHz NMOS) rather than

20MHz CMOS, so we will need to source replacements

if we are to run the CPU at 16MHz.

|

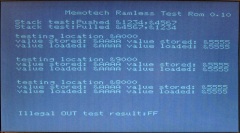

As described on the

counterfeit

chips page, I did a bit of "Googling"

and found a method of determining

programmatically whether a Z80 was an

NMOS or CMOS version.

On an NMOS Z80, an OUT

(C),0 instruction outputs 0, on a CMOS

Z80, OUT (C),0 outputs FFh. Martin used

this information to run tests on a

number of Z80 CPUs that he had to hand,

which gave the results shown

|

|

|

DS/MA |

| 20/11/14 |

CPU

Board - Data Bus Issues

During testing of the CPU board, it

became apparent that there was a problem with the

74HC245 buffer that I had installed between the

on-board data bus and the backplane. Tony Brewer was

quickly able to pin-point the problem with the way

that I had configured the data buffer.

In my original design for the CPU

board, based on references such as Steve Ciarcia's “Build

Your Own Z80 Computer”, the address and data

buffers were configured on the outlet pins of the

Z80. Someone queried whether this position was

necessary, i.e., whether it was really necessary to

buffer the bus lines for the components installed on

the board. Not knowing the reason they were in that

position in the first place, I relocated the buffers

to the where they just buffered off-board access to

the bus lines. I was really just thinking about the

ability of the CPU to drive multiple devices on the

bus, but using CMOS devices, this is not likely to

have been a problem anyway.

Unfortunately, I had not understood

the effect that this would have, Tony advised that

the "A" side of the buffer should be connected to

the Z80 and nothing else. The "B" side of the buffer

should be connected to the memory on the CPU board

and the backplane. Tony explained that with the "B"

side of the buffer connected to the backplane only,

then there would be a conflict when the CPU was

trying to read ROM or RAM as the 74HC245 buffer

would also be driving the on-board data lines. Tony

also provided a useful reference to the

Tatung Einstein schematic.

In the short term, testing will

continue with the data buffer bypassed until I can

rework the CPU board to re-position it where it

should be.

Tony also advised that Buffer output

enables should be actively switched, rather than

just connected to ground. connected to +BUSACK (/BUSACK

inverted), not ground. /RD is much better than /WR for

direction control, but /RD by itself is not enough as

you need to cater for reading interrupt vectors if

the CTC is

on the B side of buffers.

On the subject of busses, the Z80

address bus is unidirectional, i.e., only the CPU

drives the address bus and direction is not really

meaningful. When an external device wants to take

control of the busses, it sets

BUSRQ

low to request the Z80 take the address bus, data

bus and tristate control outputs to the high

impedance state. When this is done, the CPU sets

BUSAK

low.

This is not an issue at the moment,

but should external devices, such as a DMA

controller be needed, the position of the address

buffers would be problematic as components on the

CPU board would become isolated from the address

bus.

|

TB |

| 25/11/14 |

I/O Board

- General

Printer Interface - Strobe line (Reference)

When the host transmits data to the

printer, it first places an eight-bit byte to be

sent on the DATA lines, DATA0 through DATA7. Once

those electrical levels are stable, the STROBE* line

goes LOW for 1.5 microseconds, plus or minus

500nsec. The printer is alerted to the presence of

new data when the STROBE* line goes LOW. |

DS |

| 26/11/14 |

CPU Board

- Real Time Clock We had intended

to use the Motorola bus timing mode for the RTC, but

have decided to change to the Intel mode instead, to

enable Intel mode, the MOT pin will

will now be tied to 0V, rather than 5V. For

flexibility, a jumper has been added to the board

design to enable selection of Motorola (+5V) or

Intel (0V) bus mode. |

DS |

| 30/11/14 |

I/O Board

- Serial Ports My original I/O

board design was based on the use of a Z80DART for

the serial ports, however, Martin questioned whether

the same situation would exist

as with the CTC,

i.e., that the DART had to be clocked at the same

rate as the CPU. In this case, the Zilog

documentation is a more explicit and says "“The Z80

DART uses the standard z80 single-phase system clock

to synchronise internal signals”.

Therefore the I/O board will now

use a CMOS Z84C4010 - as with the CTC, the fastest

available in a DIP package is 10MHz. |

MA/DS |

| 15/12/14 |

I/O Board

- IDE / Compact Flash interface An

82C55 Programmable Peripheral Interface (PPI) will

be used to provide an IDE interface to a Compact Flash

(CF) reader for non-volatile storage.

For 8 bit microcomputer like

MTXPlus+, a large hard disk would be overkill, and

even a relatively small Compact Flash card will

provide more than adequate storage for the system.

Compact Flash cards contain an embedded IDE/ATA

controller and can be interfaced in exactly the same

way as an IDE hard disk. CF card readers that

connect directly to an IDE interface cable are

readily available and cheap - Lez also included one

in the kits of parts that he provided.

The IDE

standard provides for both 8 and 16 bit data

transfers, as it is simpler to implement, a number

of "homebrew" IDE interfaces use 8 bit mode, but 16

bit mode will be used for MTXPlus+.

The IDE/CF interface will be based

on the

S-100 IDE Interface board found on the

S100

Computers website, but, due to space limitations

on the MTXPlus+ I/O board, will only feature a

single IDE/CF connector and a single status LED

(Activity). The intention is that the CF card will

be FAT compatible and can be written/read on a PC to

facilitate creation and editing of "disks".

The S100 site also makes available

the source code for a short diagnostic program (MYIDE.ASM)

written by the board designer. The source is in 8080

assembler, but was a lot easier for Martin to

translate to Z80 than the 8051 code that he had

seen.

This

text file, courtesy of Martin, is a copy of the

draft ANSI

standard for

IDE. |

DS/MA |

| 28/12/14 |

I/O Board

- JTAG Interface

The I/O board has two Altera EPM71xxS

CPLDs installed, these are "in-system" programmable

using a

JTAG interface. The two devices can be

multi-dropped and individually selected by the

programming software when required.

Although

I believe that the two devices will operate over

JTAG without issue, I think that it is usual to

install buffers for each device. Since board space

is at a premium, I have chosen not to install any

buffers, but each device can be

connected/disconnected to/from the JTAG lines using

jumpers on the front edge of the board. Initially,

both CPLDs will be connected to the bus, but if

problems are seen, then the devices can be

individually disconnected.

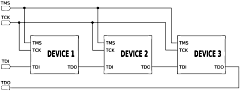

Wikipedia diagram

of diasy chaining JTAG devices TMS and

TCK are directly connected to all

devices. TDI and TDO pass through each

device in the chain.

| TDI |

Test Data In |

TDO |

Test Data Out |

| TCK |

Test Clock |

TMS |

Test Mode

Selct |

|

|

|

DS |

| |

Video Board

- VDP Update Rate The original MTX computer using

the TMS9918A/29A had the VDP interrupt pin (INT)

connected to channel 0 of the Z80 CTC (named

VDPINT

on the MTX). The VDP generates an interrupt at the

end of each active display scan, which is about

every 1/50th of a second for the PAL version. |

DS |

| 31/10/15 |

I/O Board

- Keyboard problem

When I got back to

investigating the video issues, I lost a few

hours with an annoying problem with the

keyboard that I think is worth a mention.

The keys at the very left of the keyboard

were behaving very oddly, they worked

perfectly at 4MHz, but misbehaved at faster

speeds, generating incorrect, but repeatable

codes. Replacing the keyboard had no effect

on the problem, nor did replacing the ICs on

the I/O board. |

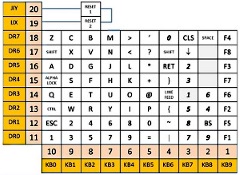

This diagram, from

my

MTX keyboard technical note, shows that

all of the affected keys are connected to

the KB0 sense line.

The wiring on my

I/O board is pretty congested and I

suspected that a bad solder joint or other

physical problem could be the cause, so I

spent quite a while checking and remaking

connections on the KB0 sense line. When that

did not reveal a problem, I did the same for

data line D0, which is used to read the KB0

sense line. |

|

The D0 connections on the

board also proved to be fine. The only

remaining component was the keyboard

interconnect cable. The cable that I had

been using was a brand-new, 40-pin IDE

cable, supplied by HP and still in it's

sealed packaging when I started to use it. I

did not have an equivalent cable easily to

hand, but when I managed to dig out another

cable, the problem was fixed!

I still

find it surprising that a "bad" cable could

work without fault at 4MHz, but fail at

faster speeds, but that was the case. The

time taken to find & fix the problem was

exacerbated by not having another cable

available - aaaarghhhh! |

|

DS |

| 30/12/15 |

Backplane Issues

I had been experiencing

issues with the stability of the system for some

time, at faster CPU speeds, the system was very

sensitive to the position and spacing of the boards

on my backplane, an issue I put down to the lack of

proper termination on the bus. I had been

considering trying to build a couple of bus

terminator boards to put at either end of the

minimum number of slots required to install the

boards, perhaps 13 backplane slots, allowing for the

required clearance between the boards.

I had

previously borrowed a reduced sized, hand wired,

backplane from Martin and had not seen the issues

when running with a smaller bus so I was pretty

confident that the issues were bus related. However,

I was not confident in my ability to design proper

bus terminators and decided on a more radical,

perhaps even reckless, course of action . . . . .

Cue the hacksaw !

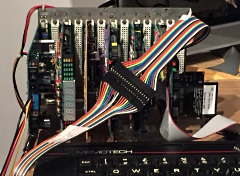

What you see here is the new, "cut-down"

(literally), MTXPlus+ system backplane with

13 slots and 6 boards installed.

Limited testing has shown that it has not

had any adverse effects and it does appear

to have helped the system's stability, at

least up to 12Mz. |

|

|

DS |

| 31/12/15 |

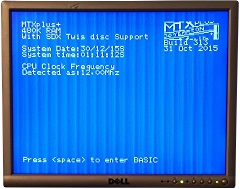

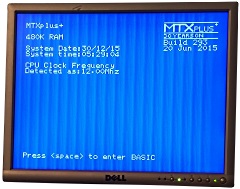

The CPU runs quite

happily at 12MHz, but you can see some video

corruption in this photo.

This is

the MTXPlus+ "Duo" ROM mono CP/M

system, booting in 40 column mode, with the

VDP writes being slowed using the CPU WAIT

signal.

The system booted CP/M

without issue, but also showed display

corruption at this speed.

|

|

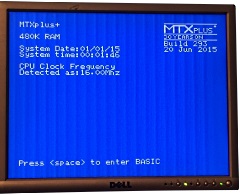

Also at 12MHz, this

is the "Duo" ROM colour CP/M

system, booting in 40 column mode. This ROM

also inserts software waits that are good

for up to 20 MHz.

Note the lack of

corruption to the video display that was

seen in the previous image. |

|

With the same

configuration, the system boots happily at

16MHz and has uncorrupted video display.

However, the system will not boot CP/M,

some video corruption is present on the 80

column screen and the system can not "see"

the Compact Flash drive. |

|

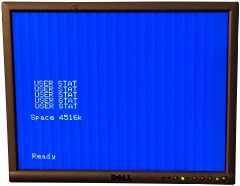

Although it is not

reliable, the CF drive occasionally responds

to commands from BASIC, in this example, after 5

attempts, the system responds to the

STAT command.

The

behavior of the CF drive was not consistent,

sometimes resulting in "BDOS Errors",

sometimes resulting in the system reporting

"No Line" in response to BASIC commands,

and, very occasionally, actually working. |

|

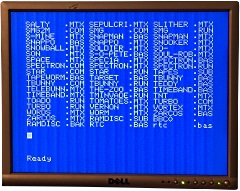

Using different

82C55s from the same or alternative

manufacturers sometime produced different

effects, but on the whole, the behavior was

pretty haphazard.

|

|

A selection of different

manufacturers 82C55s are shown in

the table. None of the chips have a

speed rating anywhere close to the

system clock speed of MTXPlus+, 8MHz

is the fastest 82C55 available, but

that is not necessarily an issue.

The key consideration is the

timing requirements given in the PIA

datasheets. The minimum Read and

Write pulse widths (in ns) are

shown. |

Manufacturer |

ID |

Speed |

Min

RD |

Min

WR |

|

Intersil |

CP82C55A-5 |

5MHz |

250 |

100 |

|

Intersil |

CP82C55A |

8MHz |

150 |

100 |

|

OKI |

M82C55A-5

|

5MHz |

300 |

300 |

| OKI |

M82C55A-2 |

8MHz |

100 |

150 |

| Intel |

8255A-5 |

5MHz |

300 |

300 |

| Intel

|

82C55A2 |

8MHz |

150 |

100 |

| Mitsubishi |

M5L8255AP-5 |

5MHz |

300 |

300 |

|

The Z80 timing diagrams show that

IORQ and RD/WR are valid for just

over 2 cycles, which translates to

the figures in this table. It can be

seen that the 5MHz PIAs are only

likely to work with a CPU clock

speed of < 8MHz and none of the

others are likely to work reliably

at 16 or 20MHz.

Using a PIA

with a minimum R/W speed of 150ns

would equate to a CPU clock speed of

~13.3MHz - this may be the limit for

MTXPlus+ using a 82C55A based disk

drive. |

CPU PHI

MHz |

Period

ns |

Z80 R/W

ns |

| 4 |

250 |

500 |

| 8 |

125 |

250 |

| 12 |

83 |

167 |

| 16 |

63 |

125 |

| 20 |

50 |

100 |

|

| |

|

| |

|

| |

|

| |

|

|

DS/MA |

| 24/01/16 |

CPU

Board - Clock speed reduced to 10MHz

Although the CPU operates quite

happily at 16MHz (and beyond), the system is

constrained by the maximum speed of the I/O and

peripherals. A lot of effort (with a great deal of

assistance from Tony) was put into getting the VDP

to operate above its rated speed by inserting

hardware wait states. Whilst the problem was not

completely resolved for speeds above 12MHz, other

constraints have emerged that mean that it's a moot

point anyway.

The I/O board uses an 82C55 PIA

to drive the Compact Flash reader, the 82C55 is only

available with a maximum speed rating of 8MHz (this

is not necessarily the system clock speed). At

speeds above, say, 12 MHz, operation of the CF

reader on MTXPlus+ has proved to be problematic. In

addition, the Z80CTC and SIO are only available in

speeds of up to 10MHz.

So, even though it has

been interesting to try and find ways to get the

MTXPlus+ prototypes to operate as fast as possible,

for a "production" version, it is more sensible to

stay within the specifications of the components,

therefore, the "nameplate" speed of MTXPlus+ is now

set at 10MHz. |

DS |

| |

|

|

| 21/08/18 |

PCB Design Notes

Like just about everything

else in the Project, the design of the MTXPlus+

PCBs is an area where I have little experience and,

to anyone with any knowledge of the subject at all,

there are likely to be any number of glaring errors

and basic design rules that I have ignored. Whilst I

have done some research and followed what I think

are good design practices, it is beyond doubt that

the boards could be better designed to reduce signal

"noise", crosstalk, etc. etc. FWIW, the fundamental

aspects that I have tried to consider are described

here.

Decoupling

The PCB designs include 0.1uF

decoupling capacitors for all of the ICs, I have

tried to locate these as close as possible to the

VCC and VSS pins at each IC.

Trace

Widths

I have used a default trace

width of 10

mils, this was the default setting in KiCAD and

critically, exceeds the minimum conductor width (>8

mils) specified by the PCB manufacturers that I use

(Itead Studio).

Obviously, a small conductor width makes routing

easier, but has less current capacity and a greater

voltage drop than a larger conductor.

The

thickness of the copper on a PCB is specified in the

weight of the copper in ounces - typically, 1oz

or 2oz. An interesting unit of measure for

thickness! The value is the resulting thickness if

the specified weight of copper were to be pressed

flat to occupy a space of 1 square foot - for 1oz of

copper, this would be 1.37mils. My PCB designs are

based on 1oz copper thickness.

KiCAD includes a

handy PCB calculator that helps determine

the impact of varying conductor size for a

given weight of copper. The user can specify

an acceptable temperature rise and conductor

length and the calculator reports the

maximum current carrying capacity and

voltage drop for the conductor.

For

the signal lines, I did not consider that

the default trace widths would have any

issues with current capacity or voltage

drop, but the power lines probably did need

special consideration. |

|

Since the MTXPlus+ PCBs are

Eurocard format (160mm x 100mm), I used 15cm as

an average estimate for conductor length and used a

permissible temperature rise setting of 10 Degrees

C. Although the maximum current carrying capacity of

the trace was a consideration, I chose the power

line trace width to ensure that the voltage drop

along the conductor length was no more than 0.2V.

The MAX705 microprocessor supervisory IC

generates a reset if the supply voltage drops below

4.65 volts, and I wanted to make sure that VCC

should not get anywhere near that on the PCBs. This

resulted in a trace width of 20 mils, which has a

current rating of ~1.5A - significantly more than

any of the PCBs require, so, it is over-specified

for the current requirement, but suitable for

limiting the voltage drop to my specification.

|

DS |

| |

|

|

| |

|

|

| |

|

|

Credits

| MA |

Martin Allcorn |

| EB |

Eugeny Brychkov |

| TB |

Tony Brewer |

| AK |

Andy Key |

| MK |

Mark Kinsey |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|