|

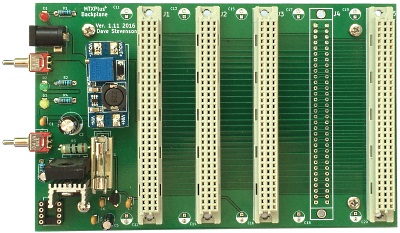

"MTX Plus+" Power Supply

Production Version

The prototype MTXPlus+ backplane had

connections for external power using two VCC planes and two ground

planes. The VCC planes were reserved for +5VDC and +3.3VDC (for

future use) and backplane pin 17C was reserved for +12VDC.

Version 1 of the power board was designed to allow an ATX power supply to feed power to the

backplane.

Version 2 of the power board

was designed to allow "wall wart" power adapters to feed power

to the backplane, after suitable conditioning on the power

board.

When I started building and testing the prototype boards for the

system, I was fortunate enough to pick up a cheap Eurocard

backplane that I used for testing, but I knew that anyone else

that might be interested in assembling their own MTXPlus+

may not be so lucky.

When I got to the point of designing PCBs for MTXPlus+,

I wanted to start with a backplane that others could use to

build the system. Although I wanted to keep the footprint small

to keep the manufacturing costs down, I realised that I could

put the power conditioning components on the backplane PCB and

do away with a separate power board and the first production PCB

was therefore a combined backplane and power board.

I was able to further simplify the design by dispensing with the

12VDC supply and regulation circuit. MTXPlus+ only

uses 12VDC for some optional features, including automatic SCART

aspect ratio switching, and perhaps a disk drive motor if a

physical disk drive were ever to be connected. Rather than

adding components to provide a regulated 12VDC supply from

another "wall wart", I have designed the board to accommodate a

cheap step up voltage module that will generate +12VDC from a

lower input voltage. You can see the small PCB installed close

to the power input connector. These modules are available for

under £1 on eBay.

At Martin's suggestions, the backplane now also incorporates the

MAX705 supervisory IC that controls system startup and reset.

The MAX705 will be removed from the CPU board when I get around

to making a CPU PCB, having reset on the backplane will save

having to build the same circuit on every CPU board that could

be used in the system.

Notes

MTXPLus+ Power Consumption

During the design phase, I "guesstimated" the power

requirements for MTXPlus+ based on the

datasheets for the major components, but once I had the

prototype boards made, I could empirically determine a

more accurate power consumption figure by removing the

supply fuse from the power board and measuring the

current in series with the load.

| Configuration |

Current drawn

(mA) |

| All bus slots empty |

17 mA (backplane LEDs) |

| I/O Board |

170 mA (CF connected) |

| Video Board |

505 mA |

| Z80 CPU Board |

235 mA |

| Z180 CPU Board |

165 mA |

| 6502 Co-Processor Board |

172 mA |

| Diagnostic Board |

128 mA (switched off) |

| Diagnostic Board |

200 mA (switched on) |

| |

|

| Typical

Configurations |

|

| Video & I/O Board |

635 mA |

| Video, I/O & Z80 CPU

Boards |

800 mA |

| Video, I/O, Diagnostic &

Z80 CPU Boards |

845 mA (Diag board off) |

| Video, I/O, Diagnostic &

Z80 CPU Boards |

1000 mA (Diag board on) |

The figures above indicate that an MTXPlus+,

configured with CPU, I/O and video boards would require

significantly less than 1A of power, even allowing for

some variation in component tolerances and some

fluctuations in the load.

Even allowing for some additional power for the serial

ports and other expansions, it should be possible to use

a high power 7805 regulator (e.g., an L78S05CV is rated

for 2A) on its own and

dispense with the TIP 2955. This can easily be done by

replacing the sense resistor with a wire link and

omitting the TIP 2955.

Temperature Considerations

The combined backplane and power board includes a linear voltage

regulator and a power transistor that are used to regulate the

raw DC voltage from the "wall wart" power adapter. These

components are cheap and provide good power regulation, the

downside is that they can generate a lot of heat. The efficiency

of a linear regulator depends on the difference between the

input and output voltages and how much current is being drawn by

your circuit. The greater the difference between input and

output voltage or the greater the current, the more heat will be

dissipated by the regulator. 1

The LM78xx series need a minimum of around 2.5VDC differential

between the supply and output voltages to provide stable

regulation and the voltage dropped over the regulator is

dissipated as heat, the greater the voltage difference, the

greater the heat produced. 9VDC and 12VDC power adapters are the

most common, but 7.5VDC adapters are also readily available and

is the suggested device to provide the power input to the PCB.

Even using a 7.5VDC supply, heat sinks will probably be needed

for the LM7805 and, if fitted, the TIP2955. With a 7.5VDC supply, these heat

sinks can be quite small, but if the user chooses to use a

larger voltage supply, larger heatsinks will almost certainly be

required.

The maximum operating junction temperature for a TIP2955 is

typically around 150 degrees C and for an LM7805, typically 125

degrees C. Although the devices will operate satisfactorily at

these temperatures, your fingers accidentally coming into

contact with them would get a nasty surprise! For personnel

protection, it is advisable to keep the surface temperature

below ~70 degrees C.

I knocked up a rough 'n' ready calculation in Excel to

calculate the size of heatsink required for a given current

consumption, there is a link to an on-line calculator at the

bottom of the page2, but you can find other calculators on the web if

you want to look. I plan to use the cheap plate type heatsinks

that rely on natural cooling (convection) but forced cooling (i.e.,

using a fan) would reduce the size of the heatsinks needed should you

want to use a higher voltage power adapter.

Heatsink thermal resistance is usually given in Degrees C/Watt

and gives a measure of the temperature rise that the heatsink

will undergo when cooled by natural convection for a given power

load that it is trying to dissipate.

References

1

sparkfun.com,

Power and

Thermal Dissipation

sparkfun.com,

Heat sinks and

thermal dissipation

electronics-cooling.com,

How to Select a Heat Sink

2

daycounter.com,

Heat Sink Temperature Calculator

designworldonline.com,

How to Select a Suitable Heat Sink

giangrandi.ch,

Calculating heat sinks

Texas Instruments,

Understanding Thermal Dissipation and Design of a Heatsink

|