|

"MTX Plus+" CPU Board V 3.0

|

CPU Board Specifications -

Version 3 |

| CPU |

Z8S180 |

20 MHz PLCC-68 Package |

| Clock Speed |

16MHz |

With 4MHz (for PSG) and Ck4/13 (for

serial ports) sub-clocks |

| RAM |

512kB |

Static RAM, rather than the

Dynamic RAM (DRAM) used in the MTX

Optional

additional SRAM, making up to 784KB of RAM available |

| (512kB) |

| ROM |

128kB |

For additional details of the ROM

configuration, see the

Memory

page |

| Glue Logic |

|

Altera Max CPLD (EPM7128SLC84) (Or 3

x GAL) |

| CTC |

Z80CTC |

Z80 Counter/Timer for serial clocks

and interrupt processing |

| RTC |

DS12887 |

24 pin encapsulated package |

| Reset |

MAX705 |

DIP8 Package - for uP supervisory

functions (CPU reset) |

Overview

My original design for the CPU

board was based on the use of discrete logic chips, like the

original MTX. The design was more or less finalised when I

decided to use a

CPLD in the design to reduce the congestion on the somewhat

cluttered circuit board and to make it easier to modify the

glue logic

should any changes be necessary. This led to the development of

the Version 2 board, you can read about its design, construction

and testing on the Version 2 CPU board page.

Along with the Zilog Z80 CPUs that Lez had given Martin and

I, he had also sent a number of enhanced Z80 CPUs, including the Zilog Z8S180. Martin used one of the Z8S180s to build another

CPU board for MTXPlus+, so I thought that I had better do the

same. As with the Version 2 board, I used an EPM7128SLC84 CPLD

for the glue logic and Martin stuck with GALs.

Based on the results of testing the Version 2 board, I made a

number of changes to the design for the Version 3 board :

- The buffers on the Address, Control and Data lines were

deleted. As MTXPlus+ is mainly based on CMOS technology, the

number of fan-outs was not an issue, so the buffers were an

unnecessary complication that could have an adverse impact

on the potential speed of the system.

- Since no peripheral devices needed it, the fixed 8MHz

clock signal on the bus was removed, freeing up the

backplane line and CPLD output for other purposes.

- The number of system clock divider options was reduced

- Added Q1 to supply power to the diagnostic LED (reducing

the current draw from the CPLD output)

Development and testing of the Version 2 board had shown that

my placement of the I/O in the CPLD was not ideal and required

more LAB resources than was necessary. For example, I had

assumed that assigning all 8 bits of the data bus to the same

LAB would be an efficient use of CPLD resources, as it turned

out, it was actually more efficient to distribute the data bits

between the 8 LABs.

For the Version 3 board, as I had a working version of the

basic CPLD code for the chip select and memory address logic, I

was able to allow the Quartus fitter more freedom to place the

I/O in the most efficient manner, rather than constraining it by

manually placing the I/O when I developed the Version 2 board.

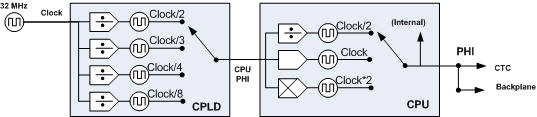

One of the enhancements in the Z8S180 CPU is its ability to

clock its internals and external devices at frequencies of half,

equal to, or double the input clock frequency. The clock

doubling feature only operates effectively with source clock

frequencies of 10-16MHz, meaning that if it is used with MTXPlus+,

the CPLD source oscillator should be no greater than 32MHz,

resulting in an input frequency to the CPU of 16MHz at the

fastest CPU board DIP switch setting.

Whilst this would allow a theoretical clock speed of 32MHz,

this is unlikely to be a realistic target for MTXPlus+,

therefore, the Version 3 CPU board will initially use a 24MHz

oscillator, giving a "stretch" target system clock speed of

24MHz with clock doubling enabled, although 20Mhz is likely to

be the best achievable with my prototype board.

Hardware - Control Bus Signals

The backplane distributes a number of control signals to the

rest of the boards in the system, the majority of these are

standard Z80 control bus signals, generated by the CPU, but

there are also a number of other signals generated or used on

the CPU board that are distributed over the backplane.

| Name |

Description |

Source |

Direction |

| Clock |

Clock source for the CPLD |

X1 |

To CPLD |

| PHI4 |

4MHz clock signal from dedicated

oscillator |

X2 |

To Backplane |

| PHI_CPU |

CPU

clock source signal, assuming 24MHz CPLD source

oscillator with the selected frequency set by bit

switches 0 to 1.

|

Bit |

0 |

1 |

Divider |

Frequency |

|

|

0 |

0 |

2 |

12 MHz (default) |

|

|

0 |

1 |

3 |

8 Mhz |

|

|

1 |

0 |

4 |

6 Mhz |

|

|

1 |

1 |

n/a |

SQW from RTC |

|

CPLD |

To CPU |

| PHI |

CPU Generated clock signal

|

Scaler |

Frequency |

|

0.5 |

6 MHz |

|

1 |

12 Mhz (default) |

|

2 |

24 Mhz |

|

CPU |

CTC & Backplane |

| SER01 |

Base Clock for serial port 1

(307.692 kHz) |

CTC |

To Backplane |

| SER02 |

Base Clock for serial port 2

(307.692 kHz) |

CTC |

To Backplane |

| DIAG |

Signal to the Diagnostic board to

latch 7-segment displays based on logic in the CPLD.

By reprogramming the CPLD and switching the position

of jumper J5, simple on board status conditions can

be shown using the on board "DEBUG" LED. |

CPLD |

To Diag.

board |

| /VDPINT |

Interrupt signal from VDP |

VDP |

From Video

board |

Design & Build

| |

|

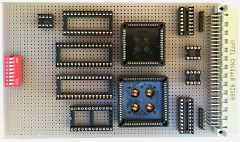

Sockets for the main

components positioned, the smaller PLCC (68 way)

socket is for the Z8S180 and the larger (84 way) one

is for the CPLD.

I wasn't able to source more

of the good quality, double sided, prototyping

boards that I had been using, this single sided

board is one of Maplin's and is of much lower

quality than my previous supply. |

|

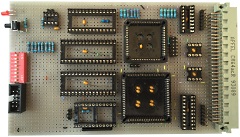

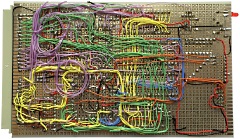

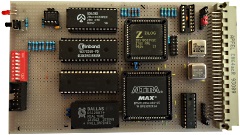

The completed board prior

to testing.

The shrouded 10-way header socket

next to the DIP switches is the JTAG connector. The

12-way header next to the 68-way PLCC socket is

connected to the Z8S180 serial lines. These will not

be used initially, but were wired to the header now,

rather than trying to add additional connections to

the PLCC socket later should they ever be used. |

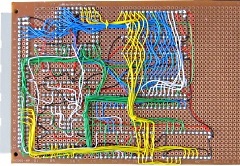

|

Wire side of the completed

board

Initial testing of the board was done

with a DVM to verify the connections were as per the

schematic, then the CPLD was installed and the ISP

JTAG connector used to load the modified program to

the CPLD. |

|

For comparison, the wire

side of Martin's Z180 board.

As usual,

looking far neater than mine! - In my defense, I

would argue that mine is much more complicated

though :-) |

|

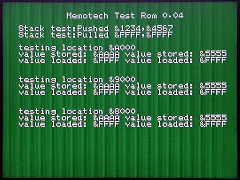

Rather than going straight

to Martin's latest Z180 version of the MTXPlus+ ROM,

I wanted to test the functionality of the board in

discrete steps.

Here you can see the output from a

very early MTXPlus+ test ROM, it does not access RAM

and only needs the CPU, CPLD and ROM installed. As

the Z180 uses RAM for its stack, the read-back

fails, but the test does prove that the CPU is

working, it can access the ROM and can drive the

video board (in MTX mode using I/O ports 01 & 02) -

a great start! |

|

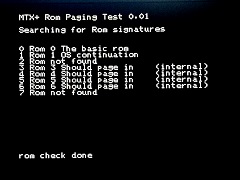

| This test ROM verified that

the MTXPlus+ component ROMs could be read and were

available to be paged in by the MTXPlus+ system. |

|

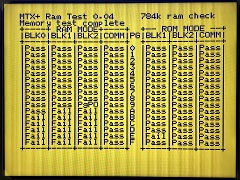

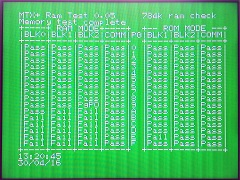

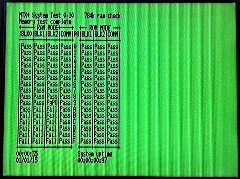

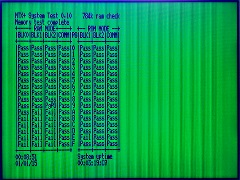

This test ROM checks the

installed RAM and verifies that the extended memory

can be paged into the address range between 4000h

and BFFFh.

The ROM was written to test up to

784kB of RAM - the maximum available on Martin's Z80

CPU board with 2 x 512kB of RAM installed. With

"only" 512k on my Z8S180 board, the failures in the

highest slots are to be expected but the test proves

that the rest of RAM is available and working. |

|

This test reads and

displays the Date & Time from the RTC.

The

RTC being used here had already been set up in the

Z80 CPU board and had the Date & Time programmed,

the values displayed are correct and current -

another good result! |

|

This version of the ROM

should exercise the CTC. As the image shows, the

system appears to "see" the CTC but the "System

uptime" freezes after 0.97 seconds.

The

first issue was there appears to be some conflict

with the CTC when the Diagnostic board is installed,

the CTC counts briefly, then stops. The second issue

was related to how I had wired up the clock on the

board. |

|

The Z180 features an

internal clock multiplier, which is capable of

running the CPU at twice the input clock speed. My

original V3 design used the clock signal generated

by the CPLD to feed the CPU clock input (EXTAL), the

CTC clock input (PHI) and the backplane PHI signal.

To keep peripherals synchronised with the CPU

clock, the system PHI signal should be driven by the

CPU's PHI output. With the Diag board removed and

the clock signal rewired, the CTC now also runs. |

|

With (almost) all of the

components and sub-systems tested, this is how the

"finished" board looked.

The one missing

component is a 74HC193, used to divide the 4Mhz

clock by 13 to provide the base clocks for the

serial ports. I don't currently have one of those,

but as the serial ports are not currently used, that

isn't really a problem. |

|

| Component side of Martin's

board |

|

| |

|

|