|

"MTX Plus+" CPU Board V 2.0

|

CPU Board Specifications -

Version 2 |

| CPU |

Z80 |

20 MHz DIP40 Package |

| Clock Speed |

16MHz |

With 8MHz, 4MHz and Ck4/13 (for

serial ports) sub-clocks |

| RAM |

512kB |

Static RAM, rather than the

Dynamic RAM (DRAM) used in the MTX

Optional

additional SRAM, making up to 784KB of RAM available |

| (512kB) |

| ROM |

128kB |

For additional details of the ROM

configuration, see the

Memory

page |

| Glue Logic |

|

Altera Max CPLD (EPM7128SLC84) (Or 3

x GAL) |

| CTC |

Z80CTC |

Z80 Counter/Timer for serial clocks

and interrupt processing |

| RTC |

DS12887 |

24 pin encapsulated package |

| Reset |

MAX705 |

DIP8 Package - for uP supervisory

functions (CPU reset) |

Overview

Hardware - Control Bus Signals - Version 2

Board

The backplane distributes a number of control signals to the

rest of the boards in the system, the majority of these are

standard Z80 control bus signals, generated by the CPU, but

there are also a number of other signals generated or used on

the CPU board that are distributed over the backplane.

| Name |

Description |

Source |

Direction |

| PHI |

System

clock signal (frequency set by bit switches 0 to 2)

|

Bit |

0 |

1 |

2 |

Frequency |

|

|

0 |

0 |

0 |

16 MHz (default) |

|

|

0 |

0 |

1 |

8 Mhz |

|

|

0 |

1 |

0 |

4 Mhz |

|

|

0 |

1 |

1 |

2 MHz |

|

|

1 |

0 |

0 |

1 MHz |

|

|

1 |

0 |

1 |

1 kHz |

|

|

1 |

1 |

0 |

8 Hz |

|

|

1 |

1 |

1 |

1 Hz |

|

CPLD |

To Backplane |

| PHI4 |

Additional 4MHz clock signal |

CPLD |

To Backplane |

| PHI8 |

Additional 8MHz clock signal |

CPLD |

To Backplane |

| SER01 |

Clock for serial port 1 |

CTC |

To Backplane |

| SER02 |

Clock for serial port 2 |

CTC |

To Backplane |

| DIAG |

Signal to the Diagnostic board to

latch 7-segment displays based on logic in the CPLD.

By reprogramming the CPLD and switching the position

of jumper J5, simple on board status conditions can

be shown using the on board "DEBUG" LED. |

CPLD |

To Diag.

board |

| /VDPINT |

Interrupt signal from VDP |

VDP |

From Video

board |

Design & Build

Martin and I will be using the same functional design for the

CPU board, but our implementation of the glue logic will be

different, as I described above, I shall be using an Altera

EPM7128S CPLD whereas Martin is going to use a number of GALs on

his board.

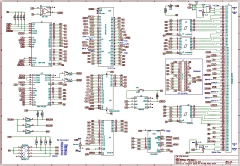

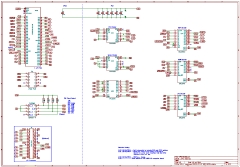

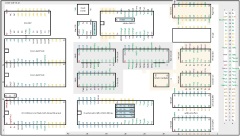

| The draft schematic for my CPU board, including the CPLD. Martin's board is essentially the same, but

the glue logic uses three GALs, a GAL22V10 for RAM

decoding, a GAL16V8 for ROM decoding and a GAL16V8

for I/O decoding. Martin also uses a 74HC273 for the

Page Port outputs and two 74HC193s to divide the

32MHz oscillator frequency to generate the

sub-clocks (16MHz, 8MHz, 4MHz, 2MHz and the serial

port clock, 307KHz). |

|

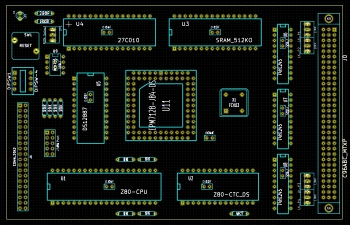

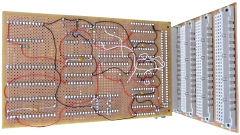

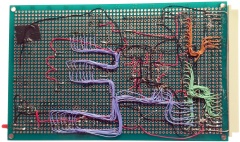

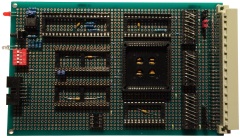

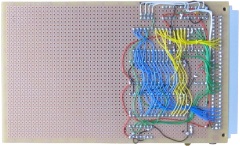

| The component layout for Martin's board (viewed

from the solder side), the GALs are the three chips

in the shaded area in the centre of the board - the

CPLD on my board will be located in the same area. |

|

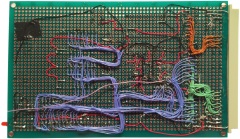

| As usual, Martin's construction is a bit ahead

of mine, a couple of photos of his board at various

stages are shown here. |

|

| The solder side of Martin's board, plugged into

his backplane. Just the power and ground

connections have been wired at this point. |

|

| Version 2.04 of the CPU schematic. Page 1

includes the components common to the CPLD and PLD

designs.

Page 2 shows the components for the two designs

separately |

|

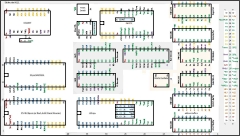

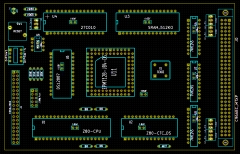

| KiCad PCB layout for the CPLD based design

(Ver.2.02 ds) |

|

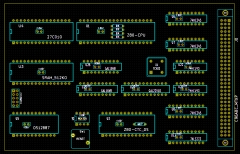

| KiCad PCB layout for the CPLD based design

(Ver.2.02 ma) |

|

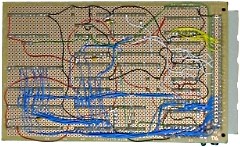

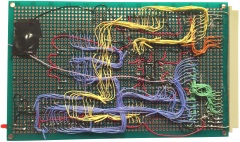

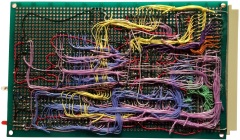

| Another update on the status of Martin's board -

with the address lines wired up to the relevant ICs

(blue) and the memory bus lines connected to the

74HC245 buffer, in preparation for wiring out to the

required IC data connections (yellow). |

|

| And now with the data bus completed - "only" the

control signals left to do |

|

| Some way behind Martin, my CPU board is finally

taking shape . . . .

You may have noticed that the layout is a bit

different to the schematic, I did a little more

"optimisation" when I was test fitting the sockets

which will hopefully make wiring it up a little

easier. |

|

| Now with the power distribution wiring done on

my board.

As you can see, the wiring below the PLCC socket

is a bit congested, this is due to the 8 pairs of

power and ground connections, along with decoupling

capacitors. The caps are squeezed into the space

between the base of the socket and the top surface

of the board - they are visible in the component

side photo. |

|

| Some progress on my board, A0 to A15 and D0 to

D7 have been wired from the bus connector to the

buffers and A0 to A7 have been fully wired up, i.e.,

from the buffer to the CPU, ROM, RAM and CPLD. |

|

| Now with the rest of the address lines wired

from the buffers to the CPU, ROM and RAM. A13 to A15

are wired to the CPLD where the address decode logic

will generate the OA14 to OA18 and RAMCS signals for

the RAM and the RA13 to RA15 and ROMCS signals for

the ROM. (These are currently not wired.)

I guess that the board is about 40% wired up at

this point. |

|

| Now with the data bus lines connected to all of

the required components. Like Martin's board

above, "only" the control lines are left to wire,

but that is still quite a few terminations to go.

Most of them are "point-to-point", rather than being

multi-dropped, so it should be relatively quick to

do the final terminations. |

|

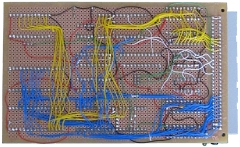

| Another update from Martin . . . .

Almost complete, just the GAL wiring to be

completed |

|

| The wiring side of my completed board, I need to

tidy of some of the longer wire runs, but it's

essentially finished - subject to testing of course. |

|

| And the component side . . . .

The ROM A16 jumper has now been fitted adjacent

to the ROM socket and an additional jumper installed

at the top left corner of the board to select

whether or not the

RESET signal is applied to the RTC.

(The

RESET pin has no effect on the clock,

calendar, or RAM) |

|

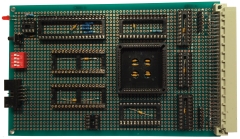

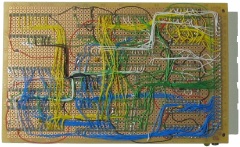

The "final" version of the board, with some

modifications made during development, including a

buffer for the Z80 control lines, a 74HC273 for the

Page Port, a GAL22V10 for Video speed optimisation

and a dedicated 4MHz oscillator for PHI4.

In

this photo, the Address, Data and Control buffers

have been bypassed using shorting links, they were

removed from the final design. |

|

Testing

Martin and I will be using different testing strategies,

Martin has gone straight to populating the board and programming

the GALs with a minimum configuration to enable 32K of the 512K

SRAM and the standard MTX ROMs in slots 0-2.

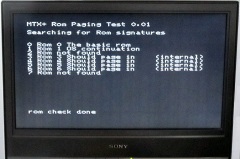

Martin's Testing

Martin's first test was to install a copy of his

RAM-less test ROM on the CPU board and run it together with

the Video board and diagnostics board plugged into the bus.

However, no output was generated on the video display, the

symptoms were the same as those seen on an MTX with bad RAM,

i.e., a black display and constant tone from the sound chip. The

status lights on the diagnostic board were also displaying

unpredictable sequences and statuses.

After trying various combinations or ROM, RAM and GAL logic,

Martin found that with the data buffer installed, there was no

output from the video board, but with the buffer linked out, the

display was active.

|

Initial Testing |

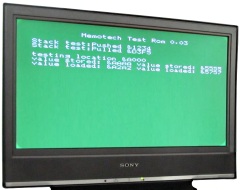

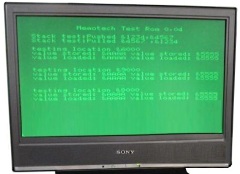

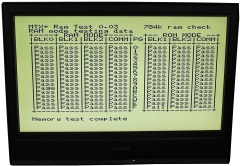

| With the GALs programmed to decode a 16K fixed

ROM and 32K of RAM with no memory paging and the

data buffer replaced with jumpers, Martin was able

to boot the CPU from a copy of his test ROM. When

either the 74HCT245 data buffer or the 74HCT273 Page

Port flip-flop was installed, there was no output to

the display, so there appeared to be something amiss

in the data bus. |

|

| The display shows the

stack test running at RAM location FF00 and the data

read back is incorrect. In a similar test with the

stack test pointing to a location in ROM, the

read-back was correct, suggesting that the problem

may have been with writing data. Using a range of

different addresses and data values for the RAM

stack test, there was no indication of obvious

faults such as stuck or inverted bits. When run

with a clock frequency of 4MHz, the video display

was as shown, when run at 8MHz, the test ran, but

with some display corruption but at 16MHz, the

system "black screened". The display corruption at

8MHz was corrected by inserting some delays in the

VDP output routines to comply with the VDP specs,

but even with delays inserted, the system would not

run at 16MHz.

At this point, Martin thought that the issue with

the system failing to run at high speeds was down to

either the VDP timing still not being correct or

there being an issue with the CPU - perhaps due to

noise or skew or the like. There were strong

indications that it was a CPU issue as the CPU was

actually HALTing when not instructed to. |

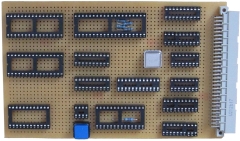

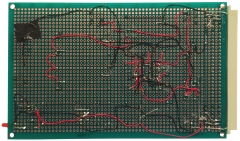

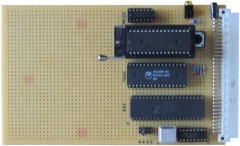

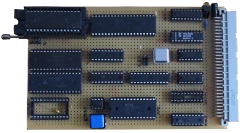

| After trying various things such as installing

additional bypass capacitors and trying another RAM

chip without success, Martin decided to build the

bare minimum CPU board shown here.

In addition to the CPU, the board has ROM, RAM,

clock, a simple R-C reset circuit and a single logic

IC (used to generate a combined logic signal for the

test ROM). |

|

| For completeness (and as further demonstration

of Martin's wiring skills), the wire side of the

minimal CPU board. |

|

| Although the screen shot is not very clear and

the colours in the display are not as expected, the

basic CPU board executed the same test ROM code that

failed on the MTXPlus+ CPU board without error. As

with the MTXPlus+ board, the ROM code could be run

at 2, 4 and 8 MHz, but the "black screen" issue was

also present at 16MHz. After a lot of

investigation, mainly by Martin, the symptoms

described had a number of unrelated causes . . . . .

. . |

|

|

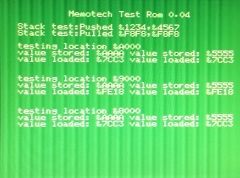

1. Clock Speed

Perhaps

the most interesting issue was that the "20 MHz Z80

CMOS" CPUs that we were using were nothing of the

kind. We found that it was possible to test from

software whether a Z80 was NMOS or CMOS, the test

shown here is running on a CMOS CPU which was able

to run at its labelled speed, whereas the "20 MHz"

versions were NMOS.

More

details of this issue can be found in

this

entry on my

Notes page. |

|

| 2. Memory Write / Read Errors

Memory write and read-back worked flawlessly on

Martin's minimum complexity test board. Apart from

having a reduced chip count, the main functional

difference between the MTXPlus+ and test CPU boards

was that the test board didn't do any memory address

decoding in PALs.

For testing purposes, Martin modified his

MTXPlus+ CPU board to simplify the memory map,

omitting any memory paging, allocating 16KB of fixed

ROM and 48K of fixed RAM. The ROM decode GAL was

replaced with a single HC32 quad OR, using two of

the gates to drive the ROM chip select

(CS)

signal and the RAM decode GAL logic was reduced to

the bare minimum to enable the 48K of RAM.

SUCCESS

!

- With this simplified memory configuration, the

MTXPlus+ CPU board booted the test ROM and ran the

RAM test routine without errors.

The root cause of the problem was that we had

errors in the PAL (Martin's board) and CPLD (my

board) address decode logic equations. A minimal

memory map was now working and would "just" need

modified to cater for the memory paging required for

the 512K RAM and 128K ROM that we were using.

(You can see the result of the RAM test running

on my board further down this

page) |

|

3.

Video Display Colour Variability

Once the

other issues had been resolved, Martin found that

the variability in the screen colours did not occur on

the MTXPlus+ CPU board. Martin has suggested that it

may have been due to differences in the effect that

the simple RC reset circuit used on the test board

had on start-up of the CPU and VDP, perhaps the VDP

was slower to start and may have missed part of the

register setup code.

As the

MTXPlus+ board, using the MAX705 based reset

circuit, does not exhibit the same behaviour, then

the issue does not really warrant

further investigation.

|

| 4. Data Buffer Problems

See the Design

Development page for details Until the design was modified and changes made to the buffer

wiring and control logic, the work-around was just to run the CPU board with the

data buffer bypassed.

|

|

"Final" Configuration & Testing |

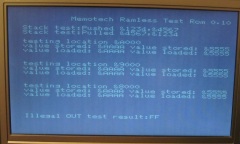

| Memory

Paging |

|

With the core functionality of the

CPU board now working, the remaining tasks were

configuration of the Page Port memory map and I/O

decoding for the RTC in the PALs / CPLD.

This

image shows the output from Martin's test ROM before

memory paging was configured. MTXPlus+ is running with a MTX512 memory

map, i.e., a fixed 16KB of ROM (0-3FFFh) and 48KB of

RAM, including the fixed RAM at 4000-BFFFh and

the "common" block at C000-FFFFh.

With no paging, "Page" faults are reported for the

"missing" RAM. |

|

| Once the GAL had been configured for RAM paging, the ROM

was able to find the test the remainder of the RAM

as it was paged into the address

range between 4000 and BFFFh. (The difference in

display colour is due to the ambient lighting when

the photos were taken, the previous photo is closer

to the true screen colour). |

|

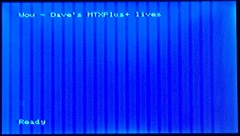

| With the GAL updated to include the

paging code and the MTX ROMs loaded into the on

board ROM, a screen shot of Martin's screen output

which, for obvious reasons, he named "So Close".

Hopefully, you recognise the screen as typical

output from the MTX BASIC ROM. The error is what you might expect if an invalid command had

been entered at the "Ready" prompt. It is likely

that with no keyboard connected, the ROM is still

trying to read the keyboard drive/sense lines and

seeing an invalid key entry. |

|

| MTXPlus+ will page ROMs into the

memory as required in the same way that Memotech did

it for the MTX. There is a slight difference in that

copies of the majority of the Memotech ROMs (apart

from ROMs 2 and 7) will be held in the single on

board ROM. The image shows another of Martin's

test programs, this one is checking that the stored

image can be accessed and available for paging. |

|

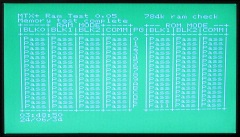

| Not content with a "mere" 512KB of

RAM on the board, Martin has allowed a bit of "scope

creep" and made 784KB of RAM available on his board

by squeezing in another 512K RAM chip. |

|

| You can see the additional RAM chip

squeezed between the original and the RTC ship.

Also note that the ROM is temporarily installed in a

ZIF socket to save wear & tear on the permanent

socket whilst frequent updates to the test ROM were

being made. |

|

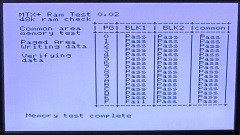

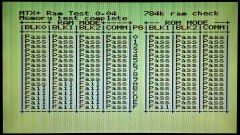

| Martin's test ROM image has been updated

to test the 784KB of RAM. The "Fail" result for

Block 1, Page F in ROM mode is "by design", thereís

nothing to gain from paging in the 2nd chip for just

16k. In addition, the MTX ROM code expects to find a

RAM page failure at some point while its starting

up, as thatís how it identifies the last good page. |

|

| Real Time

Clock |

| And now with the I/O address for the

RTC being decoded. At this point, the RTC clock

registers are being read, but the clock has not been

reset and displays whatever happened to be in the

registers in the chip. |

|

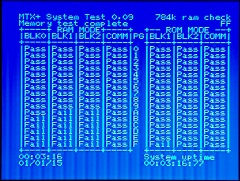

| This photo shows the output from

version 0.09 of the test ROM. At this point, the

clock has been set to 01/01/15 and code has been

added to test the CTC - the "System Up Time" is

being calculated using the CTC. |

|

My Testing

The pace of my testing was rather more leisurely than Martin's

and my intention was to make use of my MTX to MTXPlus+ bus interface adapter to

test the RAM, ROM and the associated address select logic in

individual stages to make fault finding easier should there be

any problems with the CPU board. As I was finishing off wiring

the board, I thought that a programmable status indicator,

driven by the CPLD, might be useful. Although the CPLD will have

quite a bit of spare logic capacity, there was only 1 spare I/O

pin, as it was likely to remain unused, I wired this out to the

additional LED located above the DIP switch block.

I

had spent a lot of time checking the board against the schematic

with a multi-meter to make sure that the connections went to the

right places. It is easy to check for continuity this way, but,

without testing many adjacent connections, it is not so easy to

pick up short circuits. Nevertheless, I was reasonably confident

that the wiring was OK and the initial test was to connect the

unpopulated CPU board to an MTX and check that the MTX would

operate correctly with the CPU board hanging off the MTX bus.

This did highlight a short circuit after all, there was a short

between +5V and the

M1 signal, which, not surprisingly, gave the

MTX a bit of a problem. That fault was easy to find, and quickly

fixed (the M1

connection to the CPU crossed over a 5V line and a break in the

insulation created the short).

With the CPU board connected to the MTX and the address and

data buffers not fitted, the address and data lines were only

connected as far as the buffer input pins. In this mode, only

the control signals, clock lines and Page Port lines are being

fully exposed to the MTX.

Without the buffer chips being installed (and controlled),

I needed to short out the buffer pins to connect the rest of the

address and data bus wiring to the MTX. As the circuit diagram

shows, the buffer inputs and outputs are conveniently located on

opposite sides of the chip - as you can see from the photo, it

was quite easy to make up shorting links - although the quality

of my efforts improved by the time that I got to the data

buffer. It's not really evident from the photo, but to avoid

damaging the permanent sockets, the links are installed in blank

sockets piggy-backed onto the soldered sockets.

With the links installed, no additional faults came to light

and installing the MAX705 allowed the reset

function to be tested. At this stage, I had a Eurocard sized

external reset button connected to my MTX!

Unfortunately though, I was not able to get an MTX to boot

using RAM installed on the CPU board. I initially suspected a

problem with my RAM decode logic in the CPLD and spent some time

working on this until Martin's RAM issue came to light. At that

stage, I abandoned the idea of trying to test from the MTX and

went straight to testing the CPU board with the MTXPlus+ video

board. [It is now pretty certain that my problems were

associated with my memory decode logic, I may go back an test

MTX access to the CPU board at some point - should I ever get

time.]

|

Initial Testing |

| At this point, the

effort involved in building my diagnostic board

proved its worth. I was not able to generate a

display on the monitor, even using a copy of

Martin's test ROM and no RAM installed or

configured. Although I had tested the board with a

meter a number of times, I was unable to find the

problem.

With the test ROM installed and the CPU clock set

to 2Hz, I was able to video the status display as

the program executed and upload the

video to

Facebook to see if

Martin could see anything untoward. Martin was able

to confirm that the program appeared to have loaded

and was stepping through correctly, but spotted that

there was an error in the values seen for A0. Sure

enough, I found that the daisy chained A0 line had become

detached at the ROM pin - so much for my testing!

|

| When the Z80 starts up, it executes its first

instruction from memory address 0 - the image shows

the display on the diagnostic board with the CPU in

single step mode and having loaded the instruction

at address 0 - "C3" is the Z80 JP

instruction, and causes the program to jump to the

location stored at the next memory address (in this

case, "7C"). |

|

| Having fixed the A0 problem, I was able to see

the output from Martin's test ROM running on my CPU

board.

As shown here, the memory write & read-back tests

failed, confirming that the problem was common to

both designs was and was more likely to be due to a

design/configuration problem, rather than

constructions errors. |

|

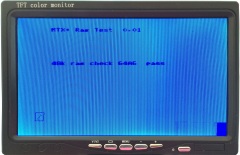

| To save a bit of space while I had a lot of equipment on my test

bench (or, dining room table, as my wife calls it), I splashed out £16 on a new 7" TFT monitor

off ebay, the output is not brilliant, but for

testing purposes it does the job well enough. The

output of the RAM test running on my CPU board,

using NTSC

composite video output to my cheap monitor (still

with the protective film on the screen which isn't

helping the sharpness of the picture). |

|

| Martin's 784KB RAM test running on my MTXPlus+,

showing "fail" for the "missing" memory that would

be in the second 512K SRAM. It appears that I may

have the MTXPlus+ equivalent of the MTX500 !

- functionally equivalent to the other

model, but with less memory |

|

| Version 0.09 of the test ROM running on my

system with output to my cheap 7" monitor.

The image is not too pretty, but all tested

systems, RAM, ROM, RTC and CTC are working as they

should. |

|

| The same test program with the output to a LCD

TV, using the composite video input and sending a

NTSC signal, screen format set to 4:3 which is

more consistent with MTX and MSX machines using the

same type of VDP. |

|

|

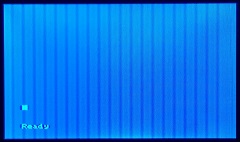

TA DA

!

With the

MTXPlus+

"megaROM" programmed with the standard MTX ROM

images, the usual MTX BASIC "Ready"

prompt was displayed, even before the

I/O board

was connected.

My CPU

board has pull-ups on the data bus that appear to

stop the bad data generating the BASIC error that

Martin had (above). |

|

|

With the

modified GAL and keyboard

ICs installed, and an original MTX computer keyboard

connected, here you can see the first simple BASIC

program running on my MTXPlus+ The system can

"see" all 512KB of RAM,

PRINT PEEK(64122) returns the expected

"15" for the number of 32KB RAM pages. |

|

Status Summary

At this point, the CPU board has pretty much been proven to

meet original design intent for MTX compatibility - at

least, when running at 4MHz like the original. However, as

things progressed during the build, a number of changes were

made to correct a couple of weaknesses in my design. Added

to this was some degree of "scope creep" that led to other

modifications and enhancements. These "design

developments" were originally documented on this page, but

the number and magnitude of the changes probably justifies

their description on a separate page that I've called, oddly

enough, Design Development.

The main items are now just bulleted below, for details of

the changes, click on the links to open the new page.

Design Development

|