|

|

Commodore PET Projects

- petSD+ |

|

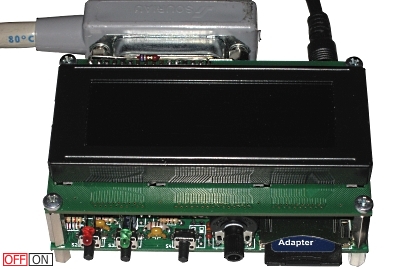

petSD+ - Assembly |

|

|

|

English |

Deutsch |

Last Firmware Update :

Get it here

Introduction

The original petSD was designed to be constructible by the

average electronics hobbyist, and one of the design

goals was to be able to use through-hole-technology

(THT) components, rather than surface mount chips.

The one exception was the FT232RL USB-serial-adapter

for which a THT equivalent was not available. The

USB - serial adapter has been dropped from the petSD+

design, the only surface mount component remaining

is the SD card reader.

Assembly of petSD+ is relatively straightforward, if you have

reasonable soldering skills and some experience of constructing

electronics projects, then you should have little difficulty

with self-assembly and you can skip to the

assembly details. However, it is probably not a good project

for a novice to start out on.

Before you start to build your petSD+, you should read through

this page and study the photos to satisfy yourself that your

skills are up to it. If you have any doubts about your ability

to follow the steps below and make a reasonable job of building

petSD+, I would strongly advise that you reconsider whether your

should attempt to build it yourself. At the very least, get some

practice with soldering components onto a piece of prototype

board before you take the plunge and have a go at petSD+.

Tools Required

The tools listed here are the bare minimum that you will need,

most hobbyists will have considerably more tools at their

disposal which will likely make construction easier.

| Tool |

Minimum |

Notes |

| Soldering iron |

20-25W

Fine

(conical) tip

No

temperature control

|

A temperature controlled solder station allows

the user to have much more control over the tip

temperature and reduces the risk of damaging the

component or PCB tracks.

In this case, the most sensitive components,

i.e., the ICs, should all be mounted in sockets.

With care, the passive components can be soldered

using a very basic iron with little risk. |

| Soldering iron stand |

A simple

metal stand |

More advanced (i.e., more expensive) cradles may

include lights, magnifying glasses, clamps to hold

the work-piece etc. |

| Solder |

From your plumber ? |

NO !

You need a good quality, electronics grade,

solder. I use 0.7mm diameter, 60% Tin/40% Lead

solder with integral flux.

Due to the

potential health risks associated with

lead,

in recent years, the use of lead based solder in

manufacturing has been phased out (see

RoHS). Lead-free solders are available, but, are

a bit more difficult to work with as they have

higher melting points and don't flow as easily.

When using lead based solder, take sensible

precautions, such as having adequate ventilation.

not breathing in the fumes (that applies to all

solders), etc. |

| Test equipment |

Continuity tester

Preferably with an audible alert (buzzer) |

The first task is installation of the SD card

reader, it is critical that its installation has

been proven before progressing with the build as it

will be almost impossible to correct after the board

has been completed. The minimum requirement is for

a basic continuity tester, but a basic multi-meter

than can measure voltage and resistance is recommended,

particularly if you need to fault-find a non-working

board. |

| Various |

|

Good quality miscellaneous tools, small

side-cutters, long nose pliers, etc. etc. |

Parts Required

If you have purchased a kit of parts for petSD+, or you are

gathering the parts together yourself, make sure that you have

the parts listed on this page.

Notes :

-

Some parts are optional, depending on

whether you need the real time clock or the LCD display and

whether you choose to mount petSD+ internally or externally

to your PET

-

The PCB includes an In-System Programming

(ISP) port for programming the MCU for first use, when the

device configuration "fuses" are set and a boot loader is loaded for the first time.

Once the boot loader has been configured, the application

firmware can be loaded from the SD card. Since the petSD+ parts kit will include a

pre-programmed MCU, the ISP port header will not be included

in the parts kit.

-

petSD+ requires a +5V power supply for

operation, this can be provided in a couple of ways - either

from the PET cassette port using a custom cable (available

as an additional option), or using a stand alone, "wall

wart", PSU rated for at least 500mA at 5 volts. If

mounted internally, power can be

picked up from a convenient place on the PET PCB.

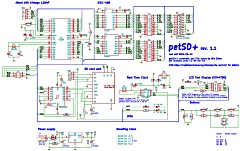

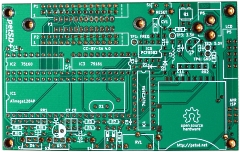

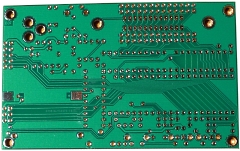

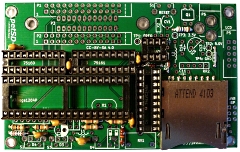

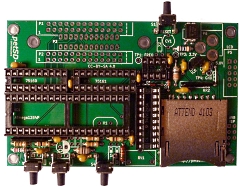

Assembly Instructions - PCB Version 1.1

Older Versions : PCB Version 1.0

|

|

|

| petSD+ Schematic |

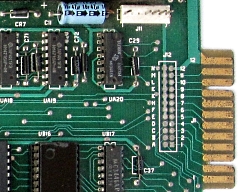

PCB Component Side |

PCB

Solder Side |

| The

parts list includes a suggested order for

mounting the components, with the exception of the

SD card slot, it isn't essential that you

follow the sequence indicated, but the sequence

follows a logical order that has been shown to work

and allows the parts

to be installed without obstructing the installation

of components to be mounted later in the sequence.

|

The first item to be mounted and

tested must be the SD card slot.

It is the

only surface mount component and it is

easier to mount it without having to worry about

other, already placed, components. More importantly,

if there is a problem with the

installation of the card slot, it will

be almost impossible to fix it after the

surrounding parts are soldered in.

Please pay particular attention to

installation and testing of the card

slot before moving on. |

The

instructions and most of the photos below were

provided by Nils based on his work when he created

the first of the petSD+ prototype boards. The medium

sized images on this page should be adequate to help

you identify the location of the components, but for

more detail, click on the image to open up the full

size photo. |

| Steps only required if

the optional components are to be

included |

|

|

LCD Display - this

is the recommended option |

|

|

Real Time Clock -

this is the recommended option |

| |

Location dependent

on internal / external mounting choice -

see notes |

|

|

Seq. No. |

Description / notes |

Photo |

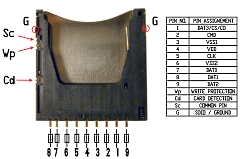

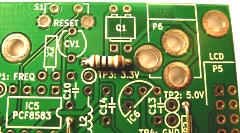

| 1 |

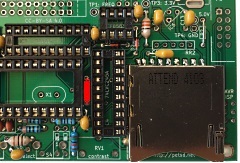

Details for the SD Card slot - model : Attend

104H-TDA0-R As you can see, the contacts,

particularly those for, Signal Common

(Sc), Write Protect (Wp) and

Card Detect (Cd) are a bit on the small

side, with Sc and Wp very close together ! |

|

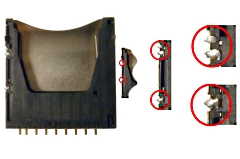

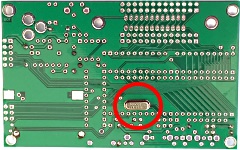

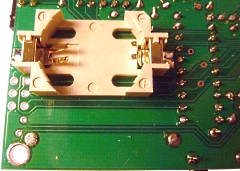

| 1 |

Mount the SD card slot

For maximum stability, the slot should be placed

with the two locating pins near the front of the

slot set into the holes provided.

The slot should be

positioned as far to the left as the solder pad

positions will allow to ensure that there is enough

room for the spacer bolt to the right.

Here, an unsoldered DIP-20

socket has been been placed in the IC4 position to

ensure that there is acceptable clearance on both

sides. |

|

| 1 |

Apply some solder onto the

three pads on the left side of the slot first, then

place the slot, clean your soldering iron tip heat

the leads only without applying extra solder.

The solder that you applied

before should melt and give a good connection

without shorts. The remaining terminals at the rear

of the SD card slot should now be soldered to the

PCB.

Verify

your work with a continuity tester and an SD card |

|

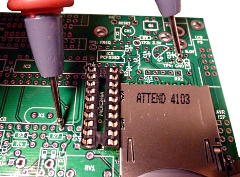

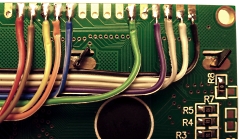

| 1 |

Set the card's Write Protect

(WP) switch to the LOCKed position (writes disabled)

- insert the card - measure between Signal

Common and pin

20 of the MCU (IC1) (Write Protect) as shown

Provided that your continuity tester comes with a

buzzer:

If the card is completely inserted with write

protect on, there will be silence. If it is removed

half the way, it will beep. If this is not the case,

either the Wp, the common connection

Sc or both are

bad. |

|

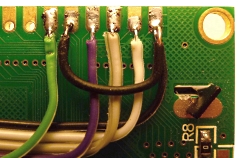

| 1 |

Verify the Card Detect switch

Measure between ground and pin 19 of the MCU as

shown

If the card is pushed in completely, it will

beep, if it is removed (half way), there will be

silence.

Make sure, both switches are working NOW!

It will be almost impossible to fix them later!

|

|

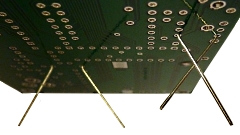

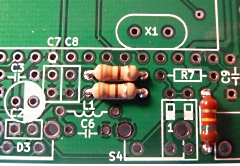

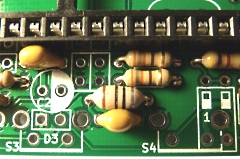

| - |

***

TIP *** Bending the

component legs

This

photo shows how the component legs should be bent

prior to soldering. The component on the left has

its legs bent outwards and can easily product shorts

to adjacent components.

The one

on the right has its legs bent inwards and is the

safer method to follow. |

|

| 2 |

|

|

(Required for LCD only) |

|

| 3 |

|

|

| D1 & D2 |

Schottky diode, DO35, p/n

BAT42 |

Check the orientation of the diode to ensure

correct polarity

(Required for RTC only) |

|

| 4 |

|

|

| 5 |

|

|

| 6 |

|

|

| 7 |

|

|

| 8 |

|

|

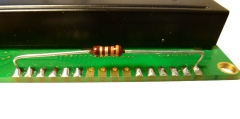

R2 is the resistor for

the LCD backlight, its value depends on the

actual display used. Placing the resistor on the

display itself, rather than on the PCB, will

make it easier to replace it should it be

necessary to change the type of the display. In

that case, a wire link should be put in the R2

position on the PCB (See "e"

below).

(Required for LCD only) |

|

| 9 |

|

|

| 10 |

|

|

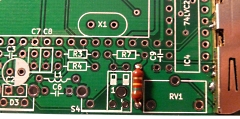

| 10a |

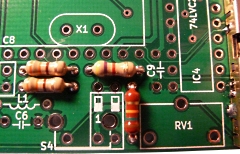

The external oscillator (X1) for

the MCU was intended to be installed inside the MCU

socket, however, on the Version 1.0 PCB, there is

not enough clearance.

The "work-around" is to

fit the oscillator to the underside of the PCB, it

is easier to install the oscillator BEFORE fitting

the socket.

This has no practical impact for

units fitted with the RTC since the coin cell holder

is also mounted on the underside of the PCB. |

|

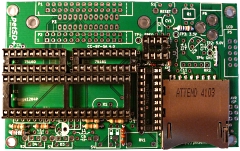

| 11 |

Install the sockets for IC1, IC2,

IC3 and IC4 |

|

|

Install the socket for IC5

(Required for the RTC only) |

| 11 |

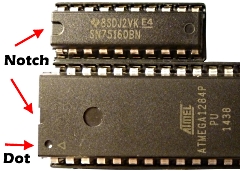

Ensure that the notch in

the sockets is placed at the mark on the PCB as

shown in this example |

|

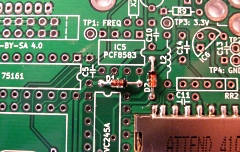

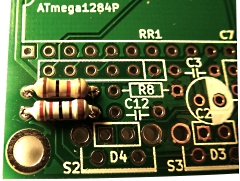

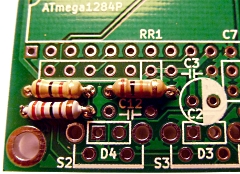

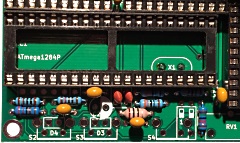

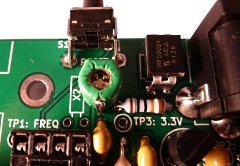

| 11a |

For PCB revision V1.1 and later, R10 is no

longer an optional component and should be installed between the

sockets for IC1 and IC4 as shown by the red mark-up

in this photo.

Note: PCB Version

1.1 is missing the component label for R10. |

|

| 12 |

|

C1, C3, C4 |

100nF |

|

C5, C6, C9 |

100nF |

|

C12 |

100nF

DELETED - DO

NOT INSTALL |

Manufacturing tolerances mean that some of the

ceramic capacitors in the kit can be somewhat

thicker than others. C4 and C5 are fitted

between IC sockets 2, 3 and 5, fit these first

so that you can choose the most suitable

capacitors for these locations.

|

|

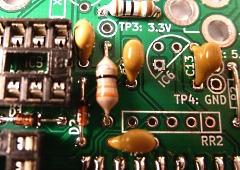

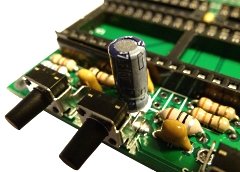

| 12a |

The capacitors for the X1 oscillator are the

orange ones just next to the MCU socket.

|

|

| 13 |

|

|

|

|

| 14 |

|

|

| 15 |

| L1 |

10 uH, 200 mA, diameter <= 4 mm |

|

|

| 16 |

| L2 |

33 uH, 200 mA, diameter <= 4 mm |

|

|

| 17 |

Take care to position the

transistor correctly, as shown

|

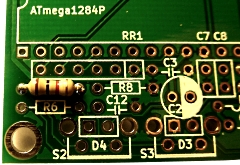

|

| 18 |

| RR1 |

5 x 10k Resistor Package |

Ensure that the "dot" on the

package is aligned with the index mark on the

PCB (the square box at one end of the RR1

stencil)

|

|

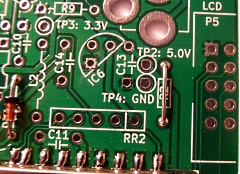

| 19 |

| RR2 |

4 x 47k Resistor Package |

Ensure that the "dot" on the package

is aligned with the index mark on the PCB (the

square box at one end of the RR1 stencil) |

|

| 20 |

|

|

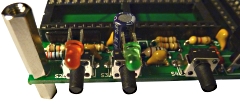

| 21 |

|

S1 |

APEM PHAP3305B (Reset) |

|

|

|

S2 |

APEM

PHAP3305B |

("Previous") |

|

S3 |

APEM

PHAP3305B |

("Next") |

|

S4 |

APEM

PHAP3305B |

("Select") |

The

default (preferred) location for these switches is

on the PCB, if petSD+ is to be mounted internally to

the PET, these switches and LCD display can be

mounted remotely. |

| 22 |

|

|

| P5 |

10 Pin box header |

(LCD connector) |

Ensure header is located with

keyway facing inwards

(Required for LCD only)

|

|

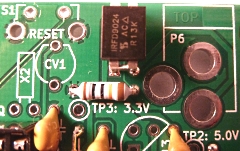

| 23 |

|

P6 |

Barrel jack,

6.3x2.1mm |

***

TIP *** Positioning the

power socket

It is very easy to end up with the power socket

off-centre, this can look very ugly but securing

the socket with a small amount of glue will

allow it to be accurately placed before

soldering .

|

|

| 24 |

Ensure

that the polarity is correct |

|

| 25 |

|

|

|

CV1 |

5-25pF

Variable Capacitor |

|

|

| 26 |

|

|

|

|

| 27 |

| |

|

|

|

|

|

P1, P2 |

2 x 12 or 2 x 13 Pin Headers (for

IEEE-488) |

|

Ensure headers are located with

keyway facing inwards |

|

OR |

|

|

|

|

| |

|

|

P3 |

IEEE-488

Connector |

| |

|

| The PCB has header

positions for either a

proper IEEE-488 connector or

2 x dual row pin headers which can be

used for in/out IEEE-488 ribbon cable

connections. Note : The PCB has

space for only 1 of these options |

|

|

| 28 |

|

|

|

X2 |

32.768 kHz oscillator for RTC |

Take care

to not short the crystal's case with one of the two

connections, make sure that there is some clearance

between the can and the PCB. Verify that there are

no shorts with the continuity tester. To ground the

case, apply some extra solder at the top end of the

can and bridge between the can and the reset switch

ground connection. |

|

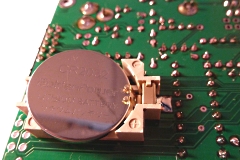

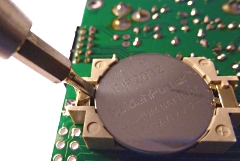

| 29 |

|

|

|

|

CR2032 Battery holder, SMD |

Take care

to make sure that the positive and negative

terminals are placed correctly - the "+"

connection should be towards the centre of the PCB.

To reduce

the stress on the battery connections to the PCB,

you could apply a little glue to the battery holder

prior to soldering. |

|

| 30 |

|

|

|

BT1 |

CR2032 Coin Cell battery |

To plug

in the battery, place it so that it lays under the

two golden fingers at the right side, then press and

move the battery to the right until it snaps in. |

|

| Info |

|

|

To remove the battery, use a

flat screw driver to lever the battery out of the

holder.

The screw driver / lever should move the battery

to the right and upwards at the same time. |

|

| 31 |

|

|

| |

M3 spacer bolts, internal thread, 18 mm |

|

|

M3 distance sleeves, 8 mm |

These parts are intended for mounting the

display, however, even if not using the display,

the legs will provide a stable base of the unit.

|

|

| 32 |

The

cathode (shorter lead, flattened side of the LED)

goes into the square box on the PCB, both on the

left side. |

|

| 33 |

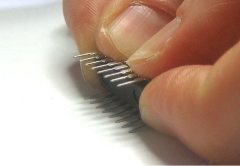

The next

step is to fit the ICs into their sockets.

The legs

on new chips have their legs slightly splayed, they

need to be bent slightly so that they fit into the

sockets (or directly into a PCB)

Images from RS-Components |

|

| 33 |

I have one of these - it's an IC lead setting

tool, the tool can dress the legs of 0.3" and 0.6"

ICs. The tool does a really good job, but it's only

shown here so that I can flaunt mine :-) |

|

| 33 |

The same effect can be achieved by carefully

bending the legs on one side at a time on a flat

surface.

(Photo from

instructables.com) |

|

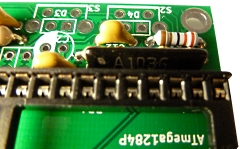

| 33 |

| Install the ICs in their

sockets |

| IC1 |

ATmega1284P-PU |

| IC2 |

SN75160BN |

| IC3 |

SN75161BN |

| IC4 |

74LVC245A |

|

IC5 |

PCF8583 |

(Required for RTC only) |

|

|

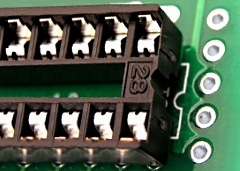

| 33 |

Take care to align the "notch" in the end of the

IC with corresponding notch printed on the PCB at

each IC. Check that every pin on each IC has been

properly inserted into its socket. |

|

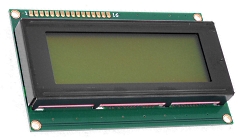

| LCD

Assembly / Fitting |

|

Seq. No. |

Description / notes |

Photo |

|

|

| Pin Number, Left to

right, facing front (unmarked) |

| 1 |

Vss |

(0V) |

| 2 |

Vdd |

(+5V) |

| 3 |

Vo |

(For LCD) |

| 4 |

RS |

(Register Select) |

| 5 |

R/W |

(Not Used) |

| 6 |

E |

(Enable) |

| 7 |

DB0 |

(Data 0 - not used) |

| 8 |

DB1 |

(Data 1 - not used) |

| 9 |

DB2 |

(Data 2 - not used) |

| 10 |

DB3 |

(Data 3 - not used) |

| 11 |

DB4 |

(Data 4) |

| 12 |

DB5 |

(Data 5) |

| 13 |

DB6 |

(Data 6) |

| 14 |

DB7 |

(Data 7) |

| 15 |

A |

(LED Anode) |

| 16 |

K |

(LED Cathode) |

|

|

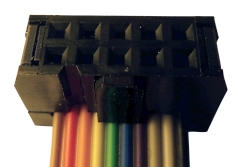

| a |

|

|

Interconnection between the PCB and the display uses

a 10-way ribbon cable, fitted with an IDC connector

at the PCB end, and soldered directly to the back of

the display at the other.

When it

has been fitted, the cable is not subjected to any

significant strain, so a low profile connector,

i.e., one with no strain relief clip fitted, is

preferred, since there is limited clearance between

the PCB and the display.

Note the

orientation of the cable with respect to the key on

the plug |

|

| b |

|

|

Lay the ribbon cable on the underside of the

display with the IDC plug connector facing towards

you and the dimple facing the centre of the display

PCB. Obviously, you need to make sure that the

cable is long enough to mate with the petSD+ PCB

header, but leaving it too long will make it

difficult to fit the display on top of the PCB. |

|

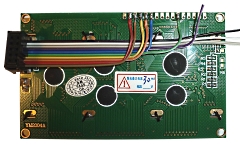

| c |

|

|

Close up of the connections |

|

| d |

|

|

Add a shorting link between the terminals shown |

|

| e |

|

|

As described in step 8, R2 is

best placed on the LCD itself, rather than on the

petSD+ PCB. Solder the resistor across terminals 1

and 16 on the front of the LCD as shown. (See the hardware page

for how to determine the correct value of R2, it

should normally be in the 3R to 6R range.) |

|

| f |

|

|

Plug the display cable into the mating connector

on the petSD+ PCB (P5) and fix the display to the M3

spacer bolts using the M3 pan head screws. |

|

|

ISP

Port Connector |

|

Seq. No. |

Description / notes |

Photo |

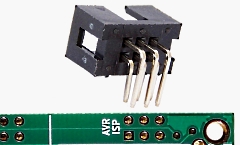

| ISP |

Should you wish to fit the ISP port connector, a

convenient point in the assembly would be at the

same time as P5 is installed (step 22.

Alternatively, the connector can be added after the

board has been completed. Note, to allow a

programmer to be connected, the connector will

protrude beyond the edge of the board and should be

mounted orientated as shown. |

|

| Debug

Message Logging (Development Tool) |

|

|

Description / notes |

Photo |

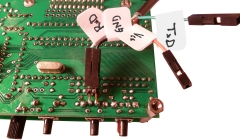

| |

It is possible to configure petSD+ to write

debug messages that can be logged to a TTL level RS232

type serial

port.

The serial line shares the port with the green

LED and debug output is enabled by setting

CONFIG_UART_DEBUG=y in configs/config-petSD+ (a

compile-time option). |

|

| |

Modern PCs are rarely fitted with a TTL RS232 port,

but USB converters are readily available.

One example, and the one used by Nils , is shown

here, it uses a PL-2303HX USB to Serial Bridge

Controller. It is available from ebay sellers for as

little as £1-£2 |

|

|

Internal Mounting Suggestions |

|

|

Description / notes |

Photo |

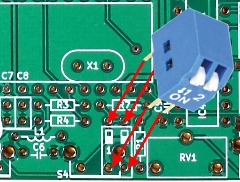

| Style |

|

DIP-SW2 |

2-way DIP switch (optional) |

If petSD+ is to be mounted internally, the LCD

and image selection switches would not be required

and a 2-way piano dip switch can (optionally) be

installed to configure the IEEE-488 device address

from 8-11 in the same way as was done with a

Commodore 1541-II drive |

|

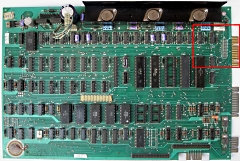

| Style |

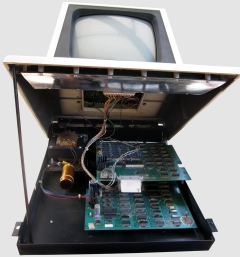

The system board used in CBM 8032/8096 (not SK)

computers has an internal pin header ("J12")for

the IEEE-488 port, adjacent to "J1", the edge

connector for the external IEEE-488 port.

On the PCB in my machine shown here, the header

position is not populated, so a 2x12, 0.1" pitch,

pin-header would need to be installed to allow the

internal petSD+ to be connected internally. |

|

| Style |

If the white connector ("J11") is fitted to the

system board, but not used, it could supply power to

petSD+, on my machine though, it is used to provide

power to the 64kB RAM board that sits above the

system board. |

|

| Style |

When mounting petSD+ internally, another option would be to copy the solution

that Dave Curran uses for some of his

petMicoSD offerings and use a couple of test

clips to pick up power from a convenient point on

the PET PCB, such as "C11", or somewhere

closer to where your petSD+ will be located.. |

|

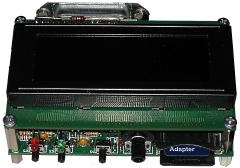

| Style |

As shown in this photo, there is lots of free

space inside a CBM 8032/8096 to locate a petSD+.

As is it highly unlikely that you will be moving

your machine around a lot, it may be acceptable to

just place the petSD+ board in the empty space at

the front left of the case - suitably

insulated from the metal base of the

computer.

|

|

| Style |

Alternatively, a better option would be to use

self adhesive PCB supports like this to fix the

petSD+ PCB to the base off the computer, raising it

off the bottom to provide clearance for the battery

holder (if fitted) and protecting against the solder

side of the board from making contact with the case. |

|

|