|

|

Commodore PET Projects

- petSD+ |

petSD+ - Hardware

|

|

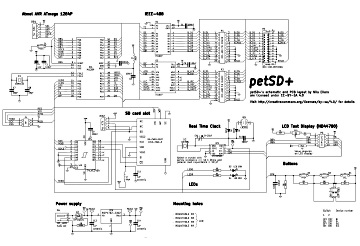

| petSD+ Draft Schematic |

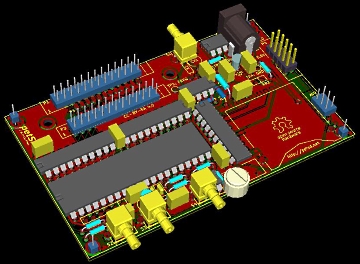

PCB 3D model |

The hardware is built around an

Atmel

ATmega

1284P

AVR microcontroller (MCU)

with 128KB of

flash

memory, 16 KB of

SRAM and a 4 KB

EEPROM,

clocked at 18.432 MHz. To make assembly easier for electronic

hobbyists, the

PDIP package was chosen for the petSD+ design . The main

components on the petSD+ PCB are :

Bus Drivers

To enable petSD+ to coexist with other devices on the

IEEE-4888 bus, it is fitted with a pair of Texas Instruments

SN75160/SN75161 IEEE-488 bus drivers, controlled by the MCU.

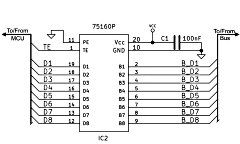

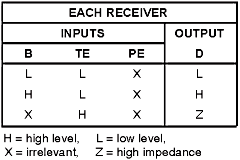

| The SN75160 8-channel IEEE-488 (GPIB)

transceiver is designed to support two-way

communications for the 8 data bits of the parallel

IEEE-488 bus using two control pins, TE (Talk

Enable) and PE (Pull-up Enable). In petSD+, TE is

controlled by the MCU and PE is tied to 0V. |

|

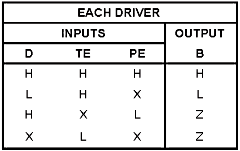

| With PE tied low, the driver outputs behave as

passive pull-ups when TE is high and are placed in

the high impedance state when TE is low. |

|

| When TE is low, the receiver bits are set to the

values of the corresponding bus data bits. |

|

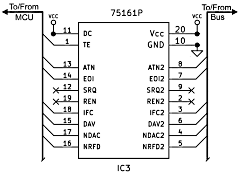

| The SN75161 8-channel IEEE-488 (GPIB)

transceiver is designed to provide the bus

management and data-transfer signals for a single

controller IEEE-488 bus system.

The direction of data is controlled by the

Direction Control (DC) and Talk Enable (TE) pins. In petSD+, TE is controlled by the MCU and DC is

pulled up to Vcc. This means that petSD+ will always

be a device and never a bus master

such as a CBM computer. In other words: you can use

it only as a device attached to a computer but never

"stand-alone" with other IEEE-488 devices. |

|

|

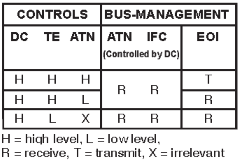

In petSD+, the Service Request (SRQ) and Remote

Enable (REN) bus management channels are not used.

With DC pulled high, the remaining bus management

channels, Attention (ATTN), Interface Clear (IFC)

and End or Identity (EOI) are set to the directions

shown in the reduced function table opposite :

(Transmit means that petSD+ writes to the IEEE-488

bus)

(Receive means that the IEEE-488 bus state is

written to petSD+ ) |

|

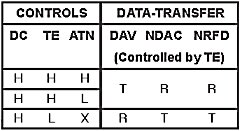

| With DC pulled high, the data transfer

channels (used for

handshaking), Data Valid (DAV), Not Data

Accepted (NDAC) and Not Ready For Data (NRFD) are

set to the directions shown in the reduced function

table opposite : |

|

Level Shifter

Since the petSD+ design uses both +3.3VDC (for the SD Card)

and

TTL voltage levels (for the other ICs), there needs to be

voltage level shifting to convert signal between +5V and

+3.3V for the SD card interface. The

74LVC245A

Octal Bus Transceiver (IC4) is used to provide level conversion

for the SD Card interface signals highlighted in the

table below :

|

74LVC245A |

74LVC245A |

SD

Card (SPI Bus Mode) |

|

| Pin |

Name |

Connection |

Pin |

Name |

Connection |

Pin |

Name |

Function |

| 2 |

A0 |

SCK |

18 |

B0 |

CLK |

5 |

CLK |

Serial Clock |

| 3 |

A1 |

MOSI |

17 |

B1 |

DI |

2 |

DI |

SPI Data In |

|

4 |

A2 |

Ground |

16 |

B2 |

n.c. |

- |

- |

- |

| 5 |

A3 |

SDCS |

15 |

B3 |

CS |

1 |

CS |

SPI Card Sel |

|

6 |

A4 |

Ground |

14 |

B4 |

n.c. |

- |

- |

- |

|

7 |

A5 |

Ground |

13 |

B5 |

n.c. |

- |

- |

- |

| 8 |

A6 |

D0 |

12 |

B6 |

MISO |

7 |

DO |

SPI Data Out |

|

9 |

A7 |

Ground |

11 |

B7 |

n.c. |

- |

- |

- |

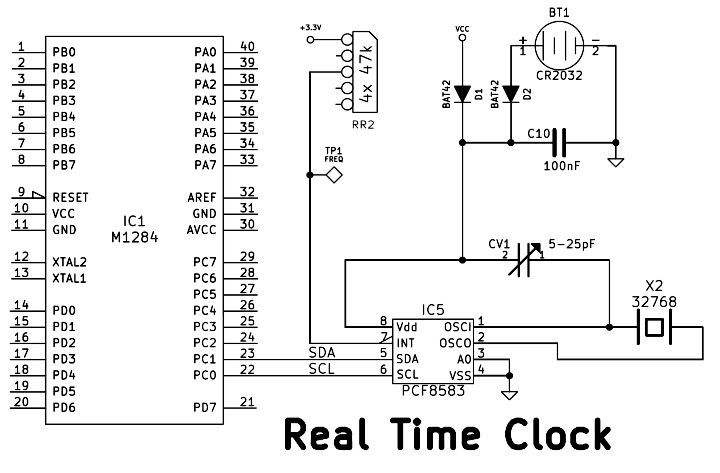

Real Time Clock

The Real Time Clock is implemented using an

NXP

PFC8583 clock and calendar chip, interfaced to the MCU using

the

I2C

bus. A 32.768 kHz quartz crystal is connected to the

RTC OSCI and OSCO pins. A trimmer capacitor between OSCI and VCC

is used for tuning the oscillator.

The PFC8583 data sheet states that "average deviations of ±5

minutes per year are possible", this equates to around 1.5

seconds per day, or expressed another way, around 19

parts-per-million (ppm). The oscillator supplied specified for

use in petSD+ has a tolerance of 20 ppm on its own, but is only

one contributor to the overall tolerance, other variables

include the capacitor tolerance and temperature.

There are a few ways of using the trimmer capacitor to adjust

the clock rate if the variance of your device is greater than

this, the easiest are :-

Both of these are constrained by the

accuracy of the test equipment being used.

For models with the Real Time Clock option, test

point TP1 on the PCB can

be used to measure the clock "tick" rate.

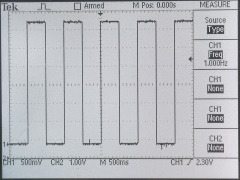

This photo is of the display on my 'scope when

measuring the frequency at TP1 for the first petSD+

that I built. As you can see, it is a nice, clean,

square wave, with a frequency of 1.000 Hz, i.e., 1

cycle/second as it should be. |

|

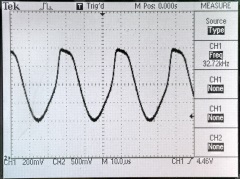

This photo is of the raw signal from the 32.768

kHz oscillator connected to the Real Time Clock chip

oscillator input on pins 1 & 2, the measured

frequency at this point was 32.72 Khz.

This

is quite a bit outside the stated tolerance of the

oscillator (20ppm) but takes no account of other

variables and is limited by the accuracy of the

'scope. |

|

Power Supply

and Voltage Regulator

The raw +5VDC power supply to the petSD+ PCB is fed to an

IRFD9024

power

MOSFET, used to provide reverse polarity protection for the

PCB.

In addition to the +5VDC supply, petSD+ requires +3.3VDC for

the SD

Card as specified by the SD Card standard. A

MCP1702-3302 voltage

regulator is used to generate the +3.3VDC supply used by the SD

Card slot and the

74LVC245A

voltage level shifter.

SD Card Slot

The card slot used in petSD+ is an

Attend 104H-TDA0-R, it is a surface mount component, but

with care, can be hand soldered onto the PCB, after

installation, it should have been tested as described in the

Assembly instructions.

During testing and normal operation, you will probably find

that SD card insertion and removal feels a little "rougher" than

with other SD card slots that you use, whilst this is unusual,

it appears to be the norm for this particular card slot. The

issue is present on the petSD+ prototypes that Nils has built

and the boards that I have assembled.

Nils has made this observation : "There's a little black

plastic finger on the left side that gives this first resistance

when inserting the card. Just out of curiosity, I broke that

finger away at one slot and looked what happened: it turned out,

this finger is used to hold the card and prevent them from just

pulling it out once it is inserted. I never experienced this on

any other SD slot I have anywhere, it really feels kind of

broken, but that's just the way this "special" slot is."

In the absence of a more technical description, I have found

that giving the card a little "wiggle" during insertion and

removal seems to make the process slightly easier.

SD Card Slot Pin-Out

| |

SD

Card (SPI Bus Mode) |

|

| Connection |

Pin |

Name |

Function |

| SDCS |

1 |

CS |

SPI Card Sel |

| MOSI |

2 |

DI |

SPI Data In |

| |

3 |

VSS1 |

Ground |

| |

4 |

VDD |

+3.3 VDC |

| SCK |

5 |

CLK |

Serial Clock |

| |

6 |

VSS2 |

Ground |

| MISO |

7 |

DO |

SPI Data Out |

| |

8 |

n.c. |

- |

| |

9 |

n.c. |

- |

| IC1 Pin 19 |

CD |

CD |

Card Detect |

| IC1 Pin 20 |

WP |

WP |

Write Protect |

| |

SC |

SC |

Signal Common |

LCD Module

petSD+ was designed to allow an (optional) 20 character x 4

line LCD display to be mounted above the PCB. The LCD driver

code in the NODISKEMU firmware is

programmed to drive displays fitted with an

Hitachi HD44780, or compatible, LCD controller in 4-bit

mode.

| HD44780 LCD Module

(or Compatible) |

|

Pin |

Symbol |

Connected To |

P5

Pin |

Function |

| 1 |

Vss |

Power Supply |

1 |

Signal Ground for LCM (Ground) |

| 2 |

Vdd |

Power Supply |

2 |

Power Supply for LCM (+5VDC) |

| 3 |

Vo |

Power Supply |

3 |

Contrast Adjustment |

| 4 |

RS |

MCU |

4 |

Register select signal |

| 5 |

R/W |

MCU |

(1) |

Read/Write select signal (Forced Low) |

| 6 |

E |

MCU |

6 |

Operation (data read/write) enable signal |

| 7 |

DB0 |

n.c. |

n.c. |

Not used in 4 bit operation |

| 8 |

DB1 |

n.c. |

n.c. |

Not used in 4 bit operation |

| 9 |

DB3 |

n.c. |

n.c. |

Not used in 4 bit operation |

| 10 |

DB3 |

n.c. |

n.c. |

Not used in 4 bit operation |

|

11 |

DB4 |

MCU |

5 |

Data transfer from MCU to LCM |

| 12 |

DB5 |

MCU |

8 |

Data transfer from MCU to LCM |

| 13 |

DB6 |

MCU |

7 |

Data transfer from MCU to LCM |

| 14 |

DB7 |

MCU |

10 |

Data transfer from MCU to LCM |

| 15 |

A |

Power Supply |

9 |

Backlight Power |

| 16 |

K |

Power Supply |

n.c. |

To Ground via current limiting resistor, R2 |

A wide variety of compatible displays are available, with

some slight variations between them; apart from obvious

differences such as colour, the displays have a pretty much

standard design. The most important difference relevant to petSD+

is the voltage used for the LCD backlight. In some displays, a

+5V backlight supply is fine, in others, +5V will damage the

display. Resistor R2 in the petSD+ design is provided to drop

the +5V supply used for the backlight down to the appropriate

voltage for a particular display. To allow the LCD to be

replaced with a different model, the preferred location for

mounting R2 is on the LCD itself.

In order to select the appropriate resistance and power

rating values for R2, we need to know the backlight supply

voltage and operating current for the LCD module being used. If,

for example, the supply voltage is 5V, the LCD backlight voltage is specified as 4.2V and

the operating current is 260mA

| Given the relationships : |

|

and |

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

Making a 3R, 1/4 W resistor suitable

for this display |

The contrast for the display is controlled by pot VR1, but

the fixed value of R2 sets the LCD to a fixed brightness level.

To some extent, the "ideal" brightness, and hence the choice of

resistor R2, is subjective. The fixed value supplied in my kits

or fitted to pre-assembled units, should give an acceptable

level of brightness for the majority of users, however, being

located on the top of the LCD, the resistor can easily be

replaced with a different value by the end user - subject to the

electrical specification of the display being respected.

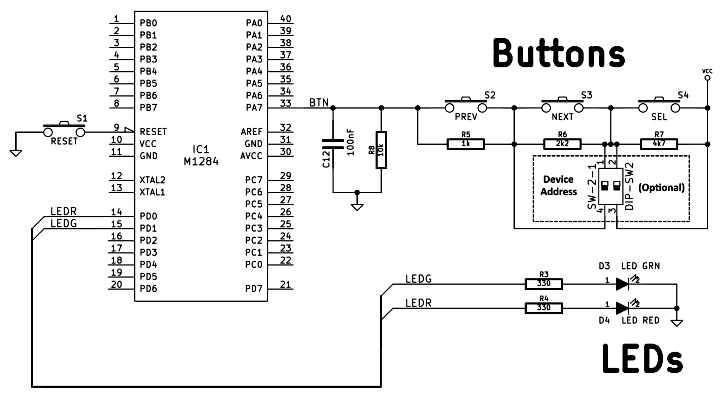

User Controls

This simplified extract from the petSD+ schematic shows how

the User Controls are connected to the MCU.

All versions of petSD+ have a RESET push-button (S1) located

at the rear of the unit, close to the power connector. (Although

not shown here, the RESET button is also connected to the ISP

connector header pins.)

Internal models also have two bit-switches (SW2-1 & SW2-2)

installed, located at the front of the unit, close to the SD

Card slot. These are used to set the Device Address, the default

position, with both switches OFF, sets Device Address 8.

External models are intended to be fitted with the LCD screen

and three additional push-buttons, Previous (S2),

Next (S3) and

Select (S4), located at the front left hand side of the unit,

along with a potentiometer to adjust the display contrast.

Operation

of these controls is described on the

User Guide page.

The ATMega1284P has 4 x 8 channel I/O ports, giving a total

of 32 programmable I/O lines available to implement all of the

features in petSD+. A quick count of the I/O requirements for

petSD+ might suggest that the MCU did not have enough I/O

channels to do the job :

| Function |

Description |

Bits/Channels |

|

IEEE-488 data bus |

8-bit parallel port |

8 |

|

IEEE-488 control signals |

NRFD, NDAC, DAV, EOI, IFC, ATN,

TE |

7 |

|

LCD data bus |

4-bit data mode |

4 |

|

LCD control bits |

Enable, Register Select |

2 |

|

SPI

bus signals for CD slot and ISP port |

MISO, MOSI, SCK |

3 |

|

I2C

bus signals data for RTC |

Serial Clock (SCL) and Data

(SDA) |

2 |

| CD Slot status bits |

Card Detect, Write Protect |

2 |

| CD Slot control bit |

SD Card Select |

1 |

| LED outputs |

1 x Red, 1 x Green LED |

2 |

| Push-buttons |

Reset,

Prev[ious], Next,

Select, address select bits1 |

4 |

| Total I/O required |

|

36 ! |

However, Nils has used a neat trick to read the status of the

option buttons, this is made possible by the flexibility of the

MCU's I/O ports. As well as being configurable as bidirectional

digital I//O ports, each of the 4 ports also has an alternate

capability :

| MCU

Port |

Alternate Function |

| A |

8-Channel, 10-bit Analogue to Digital Converters, Pin change interrupts |

| B |

SPI Bus, AI comparator, Timer/Counter inputs, Pin

change interrupts |

| C |

JTAG signals, Timer/Oscillator, I2C

signals, Pin change interrupts |

| D |

Timer/Counter outputs, Pin change interrupts |

| (For details, see

the

ATMega1284P Datasheet) |

Nils has used one of the ADC channels on Port A to read the

status of the control switches as analogue values. A 10-bit ADC

has a count range from 0-1023, using the resistor network shown

in the schematic, the calculated voltages and corresponding ADC

values for all of the key combinations are shown in the table :

| Prev |

Next |

Select |

Voltage |

ADC |

Address1 |

| 0 |

0 |

0 |

2.79 |

570 |

8 |

| 0 |

0 |

1 |

3.79 |

775 |

9 |

| 0 |

1 |

0 |

3.18 |

650 |

10 |

| 0 |

1 |

1 |

4.55 |

931 |

11 |

| 1 |

0 |

0 |

2.96 |

605 |

n/a |

| 1 |

0 |

1 |

4.10 |

839 |

n/a |

| 1 |

1 |

0 |

3.40 |

695 |

n/a |

| 1 |

1 |

1 |

5.00 |

1023 |

n/a |

1

The schematic also shows the optional bit switches

used to set the device address for internal versions

of petSD+, these switches are wired in parallel with

the Next and

Select push-button pads on the PCB.

Later versions of the petSD+ firmware include diagnostics to

check the operation of the push-buttons as described on the

User Guide page.

Connectors

petSD+ does not connect directly to

a PET computer, the "standard" build of petSD+ is fitted with an

IEEE-488 connector like those found on PET disk drives. Most PET

and CBM computers use a cheap PCB edge connector to provide

IEEE-488 connectivity, to connect petSD+ or a Commodore disk

drive, you need to use a Commodore IEEE-488 disk drive cable

(hard to find) or a

PET to IEEE-488 adapter along with a standard IEEE-488

cable.

to be continued . . . . .

Board Revisions

|

Version |

PCB

Label |

Details |

|

1.1a |

1.1 |

Missing label for R10 added (no

change to PCB label) |

| 1.1 |

1.1 |

ISP MISO Issue fixed, resistor

R10 added (missing label) |

| 1.0 |

(none) |

First production board,

required fix for ISP MISO line |

| |

|

|

| |

|

|

|