This page describes the process of

turning Martin's prototype design into a product that we can

make available for others to purchase - assuming that there is

interest of course.

I should mention at the outset, that one

my goals was to design something that, as well as being

technically sound, also worked well aesthetically. The Memotech

MTX was one of the best, if not the best, looking of the many

home computers of the early 1980s and I think that hanging

devices off the end of it on the external connector really

detracts from its sleek lines.

At the outset, I decided that I

wanted something that would be mounted internally and any I/O

connections should be as unobtrusive as possible. This

inevitably means that the size of the board will be considerably

larger than is strictly necessary if only the electronic

components were to be mounted on it.

During

prototyping, Martin had confirmed that the FPGA

development board could be mounted onto a custom PCB to

interface to the MTX and fit below the MTX keyboard, but only if the PCB was level with

the MTX computer board.

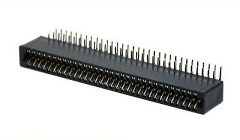

The edge connectors that

I have used for our previous MTX expansion boards are

right angled, which meant that the PCBs are at a

different level to the MTX computer board. |

|

It also

worth mentioning the way that Memotech designed the

internal edge connector does not lend itself to

connection!

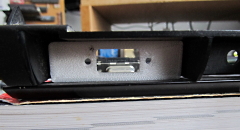

The PCB at both ends of the

connector is flush with the connector's edge. As you can

see from the edge connector photos, this means that the

ends of the connector must be modified to allow the

connector to fit over the edge of the board. |

|

It's

not as if Memotech used a different type of connector

back in the day - all of Memotech's expansion cards had

their connectors modified to fit.

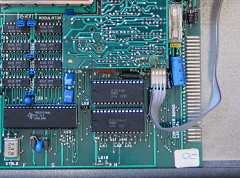

This close up

of the base of an SDX shows how Memotech sliced off the ends

of longer connectors to expose the opening between the

slots to allow the connector to slide over the PCB. |

|

Straight

connectors similar to those used by Memotech on their

expansion boards are very rare these days. We did

identify a suitable connector made by

EDAC, but these are

"order on request" items with an 18 week lead time from

Digikey, along

with a minimum order quantity of 25 with a total price

of £150.

Once MFX looked like it would likely

fly, I decided to take a punt and order connectors,

rather than have to wait months once the design was

done. (I placed the order in April 2022, by July, the

price had more than doubled!) |

|

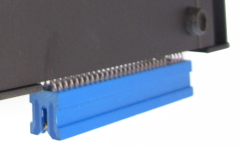

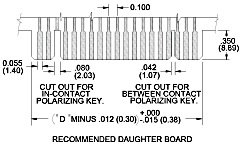

This

"recommended daughter board" drawing from the EDAC sheet

highlights where MTX made things difficult for

themselves - and for anyone developing modern day

add-ons for the MTX.

If they had left space to

attach the connector, it would have meant that

butchering the connector plug wasn't necessary. |

|

On to the

board deign . . . .

All of the add-ons that I have built for

the Memotech MTX computer have been created using

KiCad, in its own words, "A

Cross Platform and Open Source Electronics Design Automation

Suite". MFX will continue that journey . . .

In

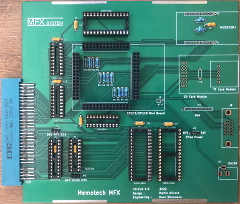

addition to the FPGA and I/O connections, the board has:

512kB SRAM for MTX RAM expansion

128kB Flash for ROM images

32kB SRAM for VDP

shadow RAM for the VGA output

GAL22V10 for

memory address decoding

74HCT245 for level

shifting between FPGA and MTX

3 x 74LVC244 for

level shifting between MTX and FPGA

WIZ810 network module |

|

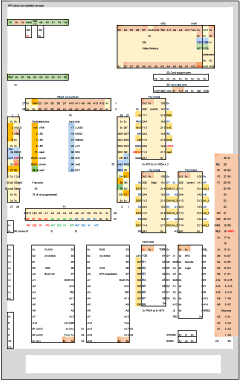

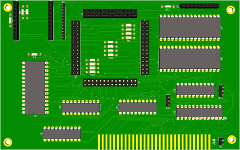

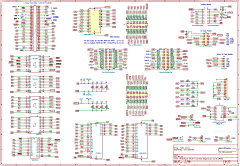

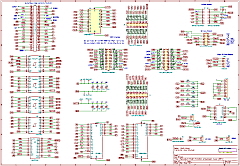

The first step is to take Martin's

"blocking" diagram and create a "proper" circuit diagram using

KiCad's schematic editor.

The first rev of the schematic |

|

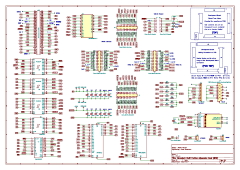

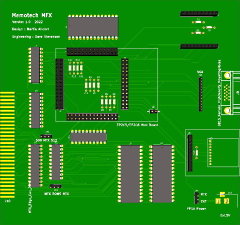

Once the

schematic has been "finalised" and checked for any

errors, footprints are assigned to the components and

board is designed using KiCad's PCB designer.

The tool has an automatic component placement feature,

but I find that it takes ages to run and get better

results when I manually place the components, taking

into account the main connections between them. |

|

I use an

older version of the

FreeRouting tool created by Alfons Wirtz. Currently,

I run it as a standalone Java application, but will

upgrade to the latest version soon.

The

Autorouter tries to route signals it finds in the KiCad

netlist and, if successful, goes on to optimise the

solution, which reduces the number of

vias in the board. |

|

I find

that it is an iterative process - I probably never get

to an optimal solution, but I can usually quickly see

where improvements can be made and move things around

accordingly until I get to something that I am happy

with.

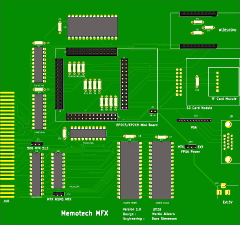

Spot the difference ? (Here, I have moved a

couple of the level shifters around and removed the

board mounted VGA connector) |

|

This

layout is Eurocard sized (160mm x 100mm) and has headers

for the WIZ810, SD card module and VGA connector. It

pretty much meets our initial aspirations regarding

board size.

Mated to an MTX computer board, it

would sit about 70mm away from the right hand end plate,

meaning that wiring to end plate mounted I/O connectors

would require internal cables. It would be possible to

run cables for the network and VGA monitor out through

the rear of the MTX case, but this would be rather messy

and short adapter/extension cables would add some cost.

Martin and I had some discussion on the best way of

facilitating connection to the PCB and decided that a

slight change of approach was needed. Rather than

minimising the PCB footprint (and cost), since any extra

space inside the MTX would be pretty much wasted, it

made more sense to dispense with the need for cables and

make the PCB wide enough to reach the end plate. This

would end up with a PCB of similar size to Memotech's

internal 80 column board, slightly increasing the cost,

but this would be more than offset by the savings made

by not requiring additional cables. |

|

For

comparison, here is a photo of the Memotech internal 80

column card, used for the SDX CP/M video output. You can

see the connectors for RGB and composite video, as well

as a hole for an external power supply (which was not

used unless the 80 column card had the DART option

installed).

We had toyed with the idea of

including a second bus connector to allow MFX to be

connected externally, but despite the larger sized PCB

having ample space, having a board this size

hanging off the end of the MTX is silly, so the idea was

dropped. |

|

| For

development, Martin's FPGA board was powered from an

external DC PSU. Since MTXs and/or their PSUs can have

some variability in their power characteristics, we

checked how Martin's system performed when the FPGA was

powered from the MTX. This resulted in a small amount of

"wobble" on the VDP AV output. This may be unique to

Martin's MTX, but provision for an external 5VDC supply

was added to the PCB design. |

|

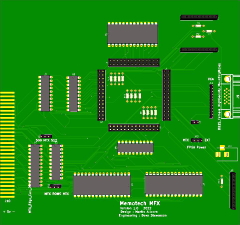

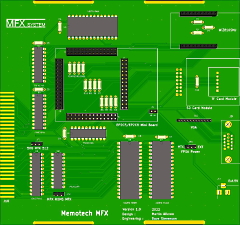

Draft

layout of a square, rather than rectangular, board.

Although there appears to be a large amount of

wasted spaced, a design such as this would allow direct

connection of the I/O through the right hand end plate.

An added benefit is that there is no need to place

components where the MTX audio and video connectors are

on the rear panel.

The fixed VGA connector has

been reinstated, along with a barrel jack for an

(optional) external 5VDC power supply. |

|

| Martin

suggested that the VGA connector could be made

accessible through the RS232 port cut-out and 3D printed

a possible insert to fill the cut-out. Unfortunately

many VGA cables are too bulky to fit into the RS232

recess. We considered a couple of ways that this might

be made to work, but decided that end plate access was

definitely the way to go. |

|

I spent

quite a bit of time trying to decide what type of SD

card module I was going to use, whether full size or

TF sized; whether bare board or something more complex?

Martin had used a bare SD slot in his prototype, the

only addition being a bypass capacitor for the power

supply to it. Breakout boards like this are quite common

and have a footprint not much bigger than the SD card

slot itself. However, many SD modules have quite a few

passives fitted and I wasn't sure why. |

|

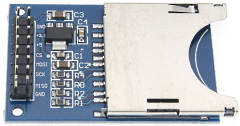

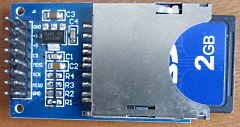

| Andy had

used a board like this for REMEMORizer. The SMT

components are a voltage regulator, a few resistors and

a few capacitors. |

|

The

voltage regulator is there to allow the 3V SD card to be

interfaced with 5v devices (this version has no level shifting

on the data lines though.)

In this image of

the circuit diagram, you can see that resistors are used

to pull the SD card data lines up to 3.3V. I was not

able to find a definitive answer on the web as to

whether these are required or not.

Martin's

system obviously worked without them and from what I

have been able to find, it is not an

SPI requirement. It seems that some SD card

manufacturers specified pull-ups for their SD cards. It

may be that some older SD cards need them, but newer

ones do not and many SD cards seem to have weak internal

pull-ups in the card. In any event, I think it safer to include

them than not, so I will be making sure that the PCB can

cater for this, larger sized, type of module. |

|

| A very

small number of the Chinese suppliers of these modules

ship them without the header pins attached, but the

majority fit the headers to the top of the PCB. So as

not to restrict the number of sources of these module, I

will use the more common ones with the headers

preinstalled. This means that the SD card module will

need to be mounted on the MFX PCB upside down - as Andy

did with REMEMORizer. |

|

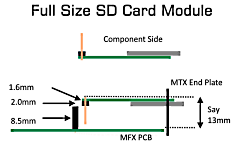

The SD

card modules with components on them are relatively long, at around 35mm, which

means that if the module is not to be permanently

soldered to the PCB, a header socket on the PCB needs to

be some distance from the right hand edge of the PCB.

The restricted clearance below the MTX keyboard PCB

means that there is not enough headroom to mount an SD

card module as it is shown in this first drafts for the

larger PCB. |

|

To get

clearance for the SD card module, it was necessary to

swap the positions of the VGA connector and SD card

module. The VGA connector can easily fit in the shallow

part of the case as the keyboard PCB stops some 30mm

short of the right hand end of the case. Moving the VGA

connector closer to the front edge of the MTX end plate

was not ideal, but appeared to be the best option.

With the components and I/O connectors placed, I

felt that I was pretty close to getting a trial run of

boards made. However, whilst this was not going to be a

first for me, I am still a novice at this stuff and was

sure there was lots of scope for improvement. |

|

You can

see in this photo of a MTX RAM card and an RS232 board,

that although Memotech did not have ground planes, the

expansion boards have large ground strips at the top and

bottom of the board.

There are "holes" in the

solder mask on these strips to allow the ground to

contact the case metal work. Memotech were not

consistent in their use - neither the MTX computer board

or the 80 column board had these strips. |

|

Many of

the 2-layer hobbyist PCBs that I have seen include

ground and/or power planes on the top/bottom of the

board. I think that this helps with noise reduction,

particularly for boards that operate at much higher

frequencies than the MTX. It appears that good design

practice is to have at least a ground plane on one or

both sides of the board - this has been added here.

There is not 100% coverage, but additional VIAs have

been added to fill the major void spaces left by the

auto-fill algorithm in KiCad. I also removed areas of

the solder mask at the board edges to allow the ground

to contact the case - though I'm sure they'll be of no

benefit here. |

|

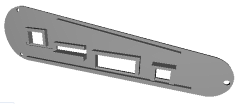

| This

mock up shows how a 3D printed end plate might look with

apertures for the I/O connectors placed to suit the PCB

above. |

|

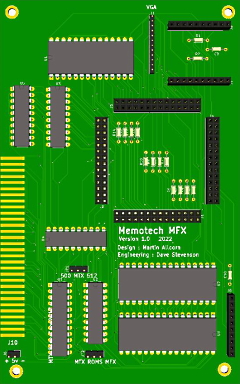

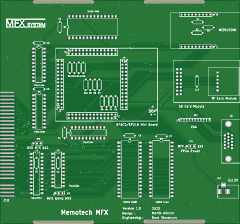

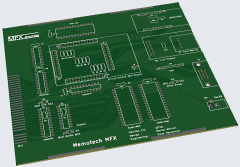

| "Final"

version of the PCB design, reflecting the changes shown

on the rendered image above |

|

OK, first

draft done - including needless complications such as

ground planes and solder mask voids as described above.

Now I just need to bite the bullet and submit an order

for PCBs, then a few weeks later - find out how many

mistakes I've made along the way!

I will likely

wait until I have a definite shipment date for the EDAC

connectors and have gathered together more of the

components that I'll need before I "push the button" on

the board's manufacture, so there is still a little time

for "tinkering".

|

Here we go

!

I tried pricing up the board with the PCB

manufacturer that I usually use, but found them to be

quite expensive for this size of PCB. There are a number

of different Chinese PCB manufactures that cater for

hobbyist projects, and by shopping around a did find

that most were cheaper.

Time will tell if the

one that I chose has the quality of my previous

supplier, but I wanted to minimise costs until I had a

proven design. |

|

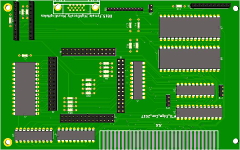

This

supplier also has a neat on-line visualisation tool -

here is their representation of the PCB. Now I just need

to wait for delivery !

Damn !

Whilst I way

playing with the online viewer, I realised that I had

made an obvious mistake and the boards would have at

least 1 issue |

|

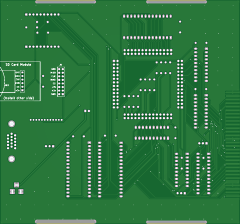

Can

you see the problem ? . . . . . . .

Looking at

the reverse side of the board, you can see that the

solder mask layer (grey) is missing on the edge

connector pads :-(

When I cloned the pads on the

footprint's component side for the solder side, I didn't

change the mask layer from front to back! It will be

difficult to remove the mask from the pads, but we'll

see if it can be done when I get the boards.

But

I am not optimistic . . . . |

|

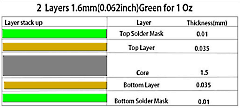

| This

image, from

pcbgogo.com shows the structure of a typical 1.6mm

PCB like the one ordered. The copper layers are "1 oz"

thick, equivalent to 35um, 1.4 mils or 0.035mm! There

won't be much copper to play with when I try to remove

the solder mask. |

|

By design,

the solder mask layers are difficult to remove, it can

be done using some quite harsh chemicals, but I have

read that good results can be achieved by mechanical

means, i.e., scraping, using, for example, a fibreglass

brush such as this

one from RS.

I have one of these in my

toolbox; they need to be used with care as they shed

tiny shards of fibreglass which can cause irritation and

pierce the skin, but this is what I am planning to try. |

|

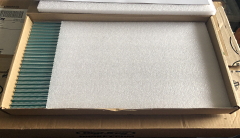

In the

meantime, the EDAC connectors from Digi-key arrived -

some 4 weeks ahead of the projected delivery date.

The size of the package took me somewhat by

surprise!

To show scale, here's a photo of the

box on my computer chair - the only contents were the 25

edge connectors that I had ordered! |

|

| The EDAC

shipping carton looked like it was designed to hold 300

connectors in two layers of 150 each. It appears that

they don't expect smaller order quantities such as mine. |

|

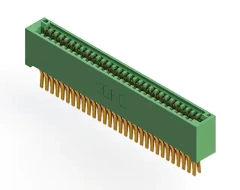

Front and

rear view of the connectors.

The datasheet

advises that the contact material is copper alloy with

"Gold Plating on mating area and Tin Plating on tails

with Nickel underplating all over". |

|

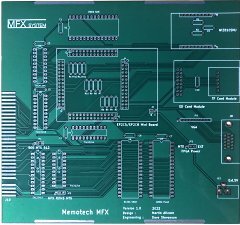

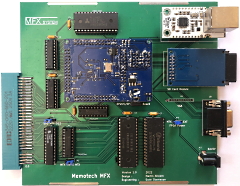

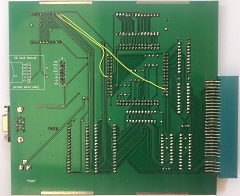

The PCBs

have arrived

Component side of the board.

It looks OK and some brief electrical checks were

fine, but I need to check positions of the components -

particularly the alignment of the headers for the FPGA

module. |

|

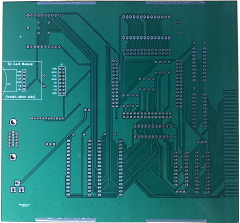

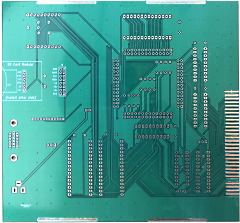

Solder

side of the board.

With the solder mask coating

the edge connector fingers as described earlier shown. |

|

I managed

to removed the solder mask from the edge connector, but

found that the fibreglass brush struggled to get through

the coating.

I used a new Stanley knife blade,

removed from the knife and scraped off the coating,

using the flat of the blade, trying to avoid digging the

point into the copper trace.

The KiCad ground

plane fill had placed some narrow ground zones between a

couple of the fingers and I was a little worried that

removal of the solder mask might make it hard to solder

the connector without creating bridges to these areas. |

|

| I did

consider scraping off these thin areas of ground plane

between the fingers, but decided not to. The close up

photo shows some small remnants of mask that shouldn't

be an issue, I didn't want to go too far and damage the

thin copper, but it was actually much more robust than I

had expected. |

|

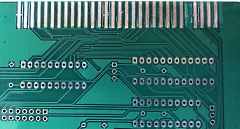

Edge

connector soldered to the board. Even with the exposed

areas of ground plane between the fingers, I managed to

fit the connector without creating any solder bridges.

The board would look better without the EDAC label

being so prominent - next time I will mount the

connector with the EDAC label on the bottom. |

|

The

headers for the FPGA seemed to be in the right place,

there was nothing else obviously wrong, so I made a

start on assembling the board.

I was still

waiting for some items to be delivered, mainly the SD

card modules, so there was not much further I could go

until they arrived. |

|

However, I

could at least test that the ROM was booting and the RAM

expansion was working.

ROM, RAM and PAL installed

with the MFX PCB pinned for a MTX500 where the PCB was

installed.

At this point, you can see probably

the largest (by area) memory only upgrade board ever

installed in an MTX ! |

|

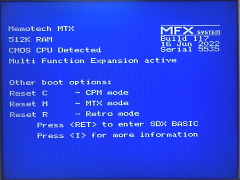

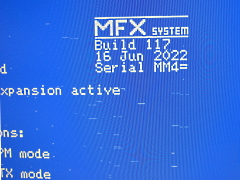

Screen

shot of the MFX boot screen displayed on the VDP output

The system is reporting 512kB of RAM - the maximum

useable. Although 544kB is installed (32k + 512k), this

is constrained by the number of available terms in the

GAL22V10.

The serial number is reporting "noise"

as the ROM cannot read valid data from the FPGA. |

|

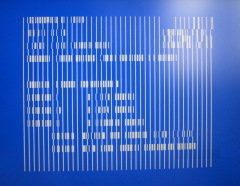

However,

with the FPGA installed, the boot screen displayed on my

VGA monitor was pretty much unreadable. Martin did not

see the same level of corruption on his screen, but he

was using faster VRAM. When when using the same speed as

me (70ns), he got the same results. (Martin also noticed

that I had made a minor error on the VGA pin-out -

another correction to the PCB was needed.)

I

ordered up some faster RAM (Alliance AS6C62256-55) but

my testing was pretty much stalled until it arrived. |

|

With the

faster VRAM, the VGA output from Martin's board was much

better, but did exhibit some noise that was not present

on the prototype board.

On the boot screen, this

noise appeared as "sparkles", typically looking like a

single pixel line in random character positions as shown

here. These "sparkles" were noticeably worse after an

attempt was made to read the SD card from SDX BASIC. |

|

The biggest concern

though was that reading the SD card was very unreliable,

more often than not, the system failed to boot to CP/M

and operation of the SD card in SDX BASIC mode failed

too. We lost quite a bit of time here, trying to get to

the bottom of the SD card issue.

During the

development of the prototype

board, Martin had some issues with noisy signals

interfering with the operation of the SD card, but that

was resolved by tidying up the wiring and removing an

unused header. Although there was a little noise on the

PCB SD card signals, it was trivial compared to when the

issue was seen on the prototype.

The most

obvious difference between the prototype and PCB boards

was that the PCB was designed to use one of the common

SD card modules with pull-ups on the data lines. |

| To

eliminate this as a possible cause of the problems,

Martin removed them from his SD card module, but this

did not make a significant difference. |

|

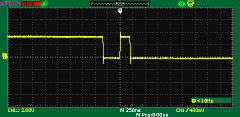

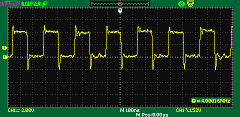

Examples

of the quality of the SD card data signals,

demonstrating that there is no appreciable noise on the

data lines.

(I had made a minor change to the

FPGA I/O allocation to help with routing of the signals

for the PCB, but none of these were associated with the

SD card and in any event, the properties of the relevant

FPGA I/O pins was identical. It turned out that, while

we did consider this as possible cause of the issue, it

proved to be a red herring. |

|

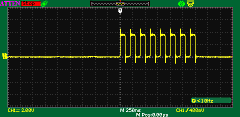

The 'scope

traces show the MTX CPU clock signal on the input and

output sides of the level shifter. The raw clock signal

has a relatively large overshoot on the falling edge but

this is likely not an issue and is much better on the

level shifter output to the FPGA.

Although there

was no indication that there was a problem with the

clock, we discussed the differences between the SD card

implementations in Andy's REMEMOTCH and REMEMOrizer. In

REMEMOTECH, the whole MTX is synthesized in the FPGA and

the SD card is clocked by the FPGA at 25MHz. In

REMEMOrizer, the SD card is clocked by the MTX CPU at

4MHz. |

|

The SD interface in

MFX was changed to mimic that it REMEMOrizer, i.e., it

was clocked at 4MHz and the data transfer synched to the

MTX clock. This resolved the SD card issues.

This was particularly puzzling as the

SD card worked without issue on the prototype, the

interface between the FPGA was simple and the PCB

checked out fine. However, since the switch to the

REMEMOrizer like implementation resolved the issue,

there was no real need to investigate further.

The video noise ("sparkles") was equally puzzling - the

video on Martin's prototype board was perfect but

building the hardware on the PCB had made things worse!

We spent a lot of time checking that the PCB was

consistent with the schematics and Martin's blocking

diagram. Martin also spent a lot of time checking for

noise and other issues but was unable to spot anything

untoward.

The eventual "fix" turned out to be

quite interesting too.

The FPGA allows the user

to configure a range of drive strengths for the I/O

pins. The range for LVTTL (3.3v) is from 4mA to 24mA

with the default at the higher level. Tucked away in the

device data sheet is the text "Using minimum settings

provides signal slew rate control to reduce system noise

and signal overshoot ". When Martin changed the output

pin configuration from 24mA to 4mA, the "noise" issue

magically went away.

Again, the fact the

prototype board did not have the "sparkles" problem was

interesting, but as the issue now appeared to be

resolved, no further time was spent on it - following

the guidance in the data sheet seemed to do the trick! |

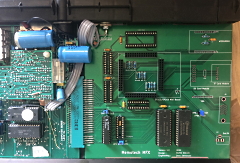

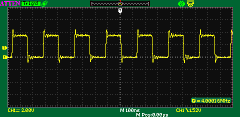

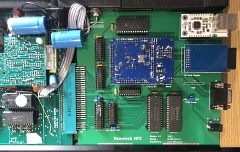

The fully

assembled PCB, with all its sub-modules fitted

The large blue board is the FPGA module

The smaller board is the SD card module

The white module is the WIZnet network adapter

(The FPGA module arrived with a few areas of excess

solder flux, it looks a bit ugly, but as it does not

affect its operation, didn't bother to try and clean it

off.) |

|

| Installed

in the MTX |

|

| End on

view, showing the fit of the FPGA, WIZnet and SD card

modules below the MTX keyboard PCB. As anticipated, it's

neat, but it fits with no problems. |

|

Just as we thought

that we were done, a really worrying issue came to

light.

Although the WIZnet interface seemed to

be working fine, we found that intermittently, files

transferred to the MTX over using FTP had errors when

they were saved to the SD card. One rare occasions, the

odd byte was being dropped from the file. For example,

when sending over an 8kB RUN file, one byte towards the

end of the file had been missed and the subsequent data

was shuffled up in the file. Strangely, when copying the

same file multiple times, most were OK, but perhaps 1 in

10 was missing the same byte in the saved file.

Quite a bit of time was lost trying to locate the source

of the issue; the signals to the WIZnet module appeared

to be "clean" and "noise" didn't really explain how the

same byte could be missed on just the odd occasion.

The WIZnet module used the CPU's Read (\RD) and

Write (\WR) signals. These signals are driven by the CPU

at one end of the MTX computer board and are distributed

to various locations on the computer board and around

the MFX PCB. Thinking about the positive effect that de-glitching

the CPU clock signal had had, Martin wondered whether

de-glitching the Read and Write signals for the WIZnet

module might improve things.

Fortunately, there

were two spare I/O pins on the FPGA module that could be

used for this purpose.

Martin modified his PCB

and added logic to de-glitch the signals for the WIZnet

module.

Ta-Da! After testing multiple transfers,

Martin was confident that this had resolved the issue.

We don't quite understand why this is the case, but

Martin theorized that it may be due to the way the the

WIZnet auto increments the pointers after a transfer

like the VDP does. However the WIZnet is MUCH newer so a

glitch that goes un-noticed by the older devices gets

accepted as an valid transaction, when the proper signal

arrives it too starts a transaction, but the pointer has

moved.

In any event, the important thing is that

the issue has been resolved. |

The modification on my PCB

It

was a fairly simple task to break the traces for the CPU

Read and Write signals below the WIZnet module and patch

the pins to the spare I/O pins on the underside of the

FPGA module. In true Memotech fashion, I used yellow for

the patch wires :-)

As with Martin's PCB,

extended testing demonstrated that the issue had be

resolved. |

|

| By now,

Martin had also produced a design for the 3D printed end

plate. Here you can see his test print using white

filament. |

|

As well as

being cheaper than the black filament that will be used

for the final print - the white allows the detail to be

seen more clearly.

You can see how Martin has

added small shrouds around the connectors to increase

the rigidity of the thin end plate. |

|

| Whilst the

positions of the connectors were acceptable, they were

not exactly flush with the printed end plate. Moving

them a couple of mm here and there will allow them all

to be flush and look better. |

|

So, it's done - Almost !

The two PCBs assembled by Martin and myself, with

the minor modifications described on this page, are

working as designed.

Having proven the design, I

had planned on using the additional PCBs that I have

left over from the first production run to supply "early

adopters", but the need for the two patch wires has made

me reconsider that. Whilst they are on the underside of

the PCB and will never be seen once the PCB has been

installed, I don't like them - though they do look like

a lot of Memotech's boards :-)

My intention now

is to get another run of PCBs done to incorporate the

changes to the WIZnet configuration, in addition, I will

take the opportunity to correct the other minor issues

identified with the V1 board :-

Correction to the solder mask layer

Correction to the VGA connector pin-out

Reduce board width by 1mm to increase clearance to the

end plate

Minor I/O connector

placement changes to better align with the end plate

|

Final

version of the schematic

- incorporating the

WIZnet modifications

Version 1.1 of the PCB has

been ordered to this design. |

|

OK,

updated PCBs have arrived and they appear to be OK.

I have just ordered some trial pieces of the 3D

printed end plate (in different materials) and have just

started assembling the first few "production" MFXs. They

will be ready to ship once I have checked the fit of the

end plate - probably another 10 days. |

|

| Martin

sent me an end plate that he printed on his 3D printer,

shown here fitted to my MTX500 with VGA and network

cables attached and the SD card inserted. It has a

slightly textured finish, but other than that, it

completes MFX perfectly! |

|

| And here

with the cables disconnected. |

|

| And the SD

card removed. |

|

The 3D end

plates that I ordered from a commercial 3D printer have

now arrived, apologies for the poor quality photos, but

hopefully, you can see the differences between them -

particularly if you open the full size photos.

From top to bottom . . .

Martin's example

FDM(ABS)

SLA(Resin)

SLS Nylon

The

three bought in items all have pretty good print

quality, the difference is obviously in the materials

used. My observations are : |

|

FDM(ABS)

The most expensive

The "blackest" of the three Slightly grainy finish

Perhaps the most rigid

SLA(Resin)

The cheapest, 40% of the ABS price

Mid range colour between the ABS and SLS

Very smooth finish, pretty close to the texture of the

Memotech

metal end plate

Not quite as

rigid as the ABS, but there’s not much in it

SLS

Nylon

The mid range material,

half way between the cost of the others

Quite coarse texture

Probably the

least black one, slightly grey looking

A little more flexible than the others, but still

acceptable |

|

Although the

colour is slightly greyer than I'd have liked, if I do

go to this vendor, then I think that the cheapest

material is actually the best. The smooth texture looks

the best of all three, but based on the samples above,

other than convenience, there is probably little to

choose between a "home" print and a professional one.

In terms of colour, Martins filament gives a

much "blacker" finish than the commercial version,

though the surface finish is not as nice; this is a

function of the print bed that Martin uses, other 3D

printers have a glass print bed which will likely

produce a much smoother finish - closer to that of the

commercial resin print.

|

| |

|