|

|

The Memotech MTX Series |

|

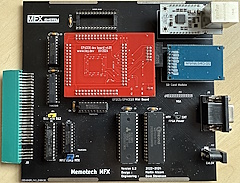

Memotech Multi-Function Expansion System

MFX Engineering Changes

one ?)

Engineering Changes

January 2024

This page describes the engineering

changes made subsequent to the first shipments of MFX. (The

firmware page describes minor

enhancements to the firmware, the focus on this page is purely

hardware.)

The biggest issue that I experienced when

completing MFX boards was

supply shortages and the variable quality of the FPGA modules

that we used in the design. (in hindsight, it would have been

better to use a device that was not so near the end of its

production life, but hey-ho!).

When MFX was released, the world was

still in the grip of the Covid pandemic and electronic parts

that were previously cheap and in plentiful supply suddenly

became scarce and correspondingly more expensive. It was hoped

that as the global situation improved, things would return to

something more like normality, but, even by early 2024, that

hadn't happened. The FPGA modules had increased significantly in

price, and although many Chinese sellers were advertising as

having them in stock, when orders were placed, they frequently

failed to deliver, and when they did, the quality was variable,

with many having faulty I/O, most likely due to poor quality

assembly, or possibly the use of factory reject FPGA chips.

Something needed to be done if MFX was going to continue without

a major redesign . . . . .

The FPGA module was so common and

(supposedly) available from so many different suppliers that I

thought that it must have been an Open Source project, at least,

originally, and as such, I expected to be able to locate the

original design files with a view to having them manufactured

and assembled by my usual PCB supplier. Unfortunately, I was not

able to find the design for the original board anywhere on the

web, however, I did find a possible solution . . . .

Ralf Thelen, the designer of a number of hardware projects

for legacy

pinball machines, had used the same FPGA development board

for a number of his projects and had experienced the same

quality issues that I had. As he notes on his website, "Because

of this I made a 99% copy of the [Cyclone II Development] board

which can be fully assembled by

JLCPCB." Ralf described this and included links to his

repository containing the design files

on this page

of his website, lisy.dev.

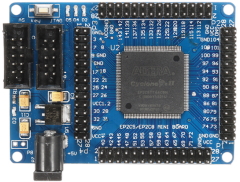

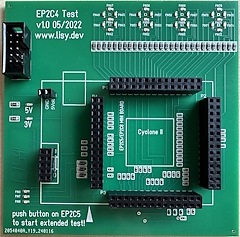

| The

original development board on the left and Ralf's on the

right - good isn't it! |

|

|

The most obvious difference is that the

JTAG port is

not fitted, but MFX doesn't need it - programming is done using

the

ASP port on the left. This made space to place all of the

components, including the oscillator and EPROM chip, on the

front side of the board which makes the cost of assembly

cheaper.

Obviously, this sounded like exactly what

I was looking for, but things got even better! Whist supplies of

the FPGA seem to be still available, at least in China, the

Cyclone II is obsolete and will surely become harder to source

before too much longer. I was really pleased when I saw that

Ralf had also done a version of the development board with the

same form factor for the Cyclone IV FPGA. This chip too is close

to "end of life", but should be available for longer than the

Cyclone II, with the added advantages that it is more powerful,

with additional internal memory and it is actually cheaper than

the Cyclone II.

It seemed that the Cyclone II version

would allow me to secure my own supply of development boards as

a like-for-like replacement for the originals and the Cyclone IV

version would also be a "drop-in" replacement with the added

benefit that the additional resources might offer scope for

further developments for MFX.

Having made contact with Ralf, I have to

say how helpful and supportive he has been. At this point,

things are at an early stage, but I am actively pursuing this

option . . .

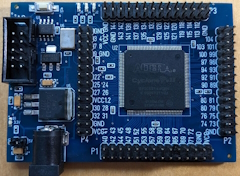

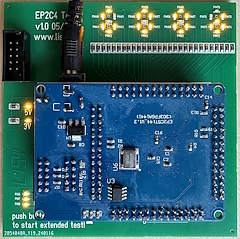

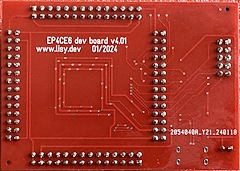

Ralf's

first Cyclone IV boards were for chips with a

BGA package. BGA provides access to more pins than

the

TQFP package so the development board, would in

theory, have more I/O capability, but as this is

constrained by the header configuration, the point is

moot.

JLCPCB charge more for mounting BGA devices

than TQFP, so Ralf changed his design to use TQFP

instead. Also note that Ralf has used a USB-C socket for

the external power connection. |

|

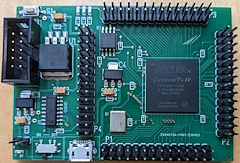

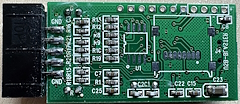

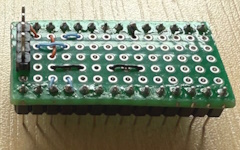

An aside - A FPGA Module Tester

Board

Given the number of Development board

failures that I had experienced, I had toyed with the idea of

trying to create a diagnostic board. Again, I was pleasantly

surprised to find that Ralf had already done exactly that and

posted the

design on his website with examples of the test output for

good and faulty boards. In summary, the board includes 28 SMT

LEDs laid out such as to create faux 4 x 7 segment displays. The

board first tests these 28 outputs, then uses them to report

failures should exercising all of the I/O reveal any faults.

I decided that this would be a great tool

to test any FPGA modules that I might get fabricated as well as to try

and reveal the exact issues with the faulty modules that I had

on hand, and hopefully, be able to detect, and ultimately repair, the hidden

defects.

When Ralf

had the board fabricated, he already had a supply of the

required pin headers, so his BOM did not include them.

However, he kindly created a BOM for me with the headers

and I used it to get some tester boards fabricated by

JLCPCB.

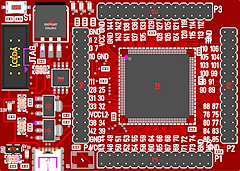

This image is the JLCPCB representation

of the

Gerber files that I uploaded with my order.

(JLCPCB charge a little more for the "hand soldering and

manual assembly" of the through-hole components, such as

the headers, but the convenience far outweighs the

small additional cost.) |

|

The

minimum PCB order was 5 pieces but you can choose to

have a smaller number assembled, with a minimum of 2.

Although I wasn't going to need 5 of these, since

the biggest elements of the cost were shipping and VAT,

I chose to have all 5 assembled anyway. (The extras are

available for sale if anyone is interested.)

Ta-da! - One of the assembled boards, ready to test my

faulty FPGA boards. |

|

The tester

board has already proven its value!

One of my

previously faulty boards, now testing as "Good". When

first run through the tester, the diagnostics identified

that Pin 8 was reading "low" when it should have been

"high". (Pin 8 is used by MFX to enable reading of the

VRAM.)

Although I had previously examined this

board under a magnifying glass, I had not spotted any

obvious errors. When the tester found an issue with Pin

8, I managed to reflow the FPGA pin which was enough to

repair the fault. |

|

Replacement FPGA Development

Board

The original Cyclone II development board

was designed to cater for the use of EP2C5 and EP2C8 devices

(although all of the boards I've seen appear to have been fitted with

the EP2C5). Since the EP2C8 has 4 fewer I/O channels available

in the FQFP package, the corresponding four pins (26, 27, 80,

81) on the original development board were tied to either 1.2v or ground

via 0 ohm resistors. Another pin (73) was connected to Vcc and

ground for use as a power up reset and one pin (17) was

connected to the 50MHz oscillator, making the signal available

for external use.

These "dedicated" pins could all be

repurposed and used as normal I/O by removing the extra

components and connections. For MFX, we didn't do this to avoid

having to modify every development board before use and

invalidating any warranty in the process.

Ralf's Cyclone IV board has omitted these

unnecessary components, meaning that it has an additional 6 I/O

pins available on the same headers should we chose to modify the MFX design in

future.

(The three pins connected to the onboard

LEDs (3, 7, 9) and pushbutton (144) have not been modified.)

The Cyclone IV is not a stock item for

JLCPCB, so I first needed to pre-buy some chips and store them

in my personal inventory before the boards could be ordered. The

price of the parts is initially estimated and you pay that

estimated price when the parts are ordered. The estimate was

quite expensive, but thankfully, when the parts arrived, the

price did drop, though I ended up having to pay currency charges

to my credit card for both the initial purchase and the refund.

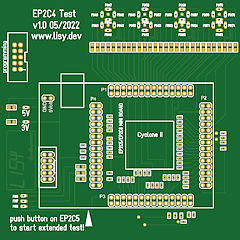

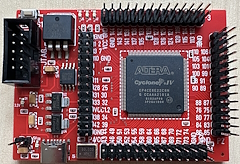

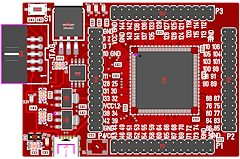

The JLCPCB

representation of the assembled board.

I thought

that it would be a good idea to make the Cyclone IV

board markedly different to the Cyclone II, so, going

with a Memotech flavour, I chose the red PCB colour. I

think that it will look awesome if I make future runs of

the MFX PCB black! |

|

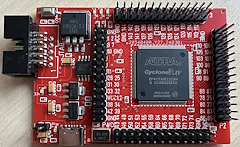

One of the

first batch of PCBs back from JLCPCB.

Loaded with

a copy of Ralf's updated test program for the EP4CE6,

the board passed testing with the Tester board. The next

step would be to load the MFX application and see how it

fared. |

|

Solder

side of the PCB.

As noted above, there are no

components on this side, this slightly reduces the cost

of manufacture. |

|

Converting the MFX FPGA firmware to Cyclone IV

When the target device is changed in

Quartus II, the pin assignments are reset. The best way to

mitigate this is to copy the existing Quartus project into a new

one and export the assignments before changing the FPGA type.

Ralf created a script file that processed the exported

assignments and remapped them for the new FPGA pin-out. After changing

the FPGA type, the remapped assignments could be imported back

into the new project.

The MFX application recompiled without

error, but a number of warnings were issued related to the

memory configuration. The Cyclone II can configure the memory

bits as M4K memory blocks (each block being 4k bits) which have been superseded by

the M9K memory type (each block being 9k bits ) in the Cyclone IV. Although the compiler

converts the memory type without issue, the M9K type is ideally

suited to the configuration of RAM with 8 data bits and 1 parity

bit and some of the MFX memory programming may benefit from

being modified to use new memory type. However, since the

internal structure is essentially an array of single bits, it

may make little difference, other than to perhaps code

readability.

When the project is compiled, Quartus II produces .pof

(Programmer Object File) and .sof (SRAM Object

File) files which are used in ASP (Active Serial Programming)

mode. After compilation, it is necessary to use the File

Conversion utility to create the JTAG .jlc

(JTAG Indirect Configuration) file used to program the EPCS16

serial configuration device on the board. (Serial configuration

devices are flash memory devices with a serial interface that

can store configuration data for FPGA devices that support

active serial configuration and reload the data to the device

upon power-up.)

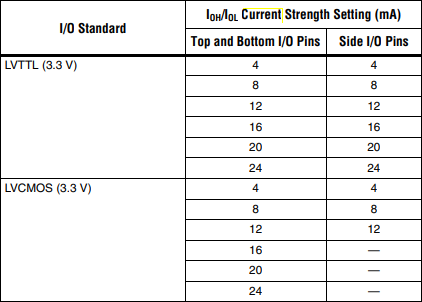

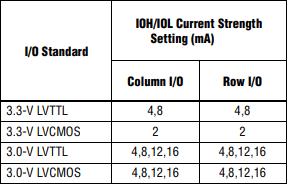

The Cyclone FPGA supports various output

pin current drive settings that can be configured to meet the

specification of the connected logic devices and to reduce

system noise. The available settings for each pin depend on the

physical location that the pin occupies on the package. The

tables below are extracted from the Cyclone Handbooks, the

available current settings for the EP2C5 are shown one the left

and the available settings for the EP4CE6 are shown on the

right.

In both cases, the default current

strength setting for a particular pin is the maximum available

setting for the I/O standard and pin position.

|

It can be seen that the available drive currents for

the EP4CE6 are much reduced from the EP2C5 |

For MFX, the FPGA is interfaced to both

3.3V LVTTL and 3.3V LVCMOS devices and during development, it

was found that the output drive currents had to be reduced to

the minimum in a number of cases to increase the stability of

the system, so the reduced drive currents available in the

Cyclone IV E were not expected to present a problem..

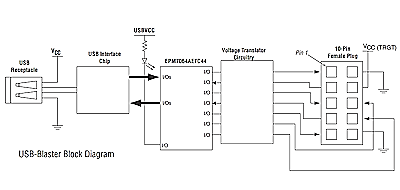

Programmer Issues

I was able to program the device in JTAG

mode using the same cheap USB Blaster clone that I used to

program the Cyclone II device. This programmer was purchased a

few years ago and works fine in ASP or JTAG mode. However, many

of the programmers that are currently available from China,

though they appear visually identical, reportedly do not work in JTAG mode. Again, Ralf Thelen has

some useful info on

his site about this issue, but in short, most of the cheap

clone devices currently available use a CH552 MCU with an

integral USB host that only works in ASP mode, at least, when

programming Cyclone FPGAs. (These devices don't have a visible

crystal oscillator but the CH552 does have a 24MHz oscillator on

the chip.)

To make sure that it would be possible

for others to program the Cyclone IV board, I bought a bunch of

the generic USB Blasters from AliExpress which turned out to be

the CH552 model and, as expected, did not work in JTAG mode, the Quartus II

Programmer utility failing with the message "209040

Can't access JTAG chain", so I needed to find an

alternative.

Martin bought his original Cyclone II

development board from

Hobby Components, along with a Hobby Components "Altera

FPGA/CPLD USB Programmer". The package looks identical to

the other USB Blaster clones apart from the Hobby Components

label. These devices are still available and listed on their

website as "USB Blaster compatible" and, having some confidence

that the claims made on a UK website would have some worth, I

bought one of these to test and confirmed that it did work in

both ASP (with Cyclone II) and JTAG (with Cyclone IV) modes.

I

inspected the internals of the three devices that I had

tried . . .

The major components in the cheap

clones from AliExpress were the CH552 type, with

resistors on the outputs to the JTAG lines.

The

rest of the components are a 662K LDO regulator and

supporting capacitors to step the 5V USB voltage down to

3.3V for the FPGA.

There are no components on

the reverse side of the PCB. |

|

My

original programmer was identical to the STM32 device

with the green PCB on Ralf's site, including the STM32,

8Mhz oscillator and HC244.

(All of the working

Blasters on Ralf's site include a '244 (level

shifter/buffer) on the outputs to the JTAG lines - could

that be the difference?) |

|

| The

reverse side of the PCB has quite a few passive

components fitted, including the capacitors for the

AMS1117 3.3V LDO regulator and resistors on the JTAG

lines. |

|

The Hobby

Components device was much more basic than my old

version, the layout was very similar to the AE clones,

it had a 16 pin chip that had had its surface etched to

remove its identification.

I suspect that it

probably did use a CH552 as there was no external

oscillator fitted and the chip footprint was the same.

However, there was a LC244A fitted on the JTAG lines.

(NB: Bill bought a Blaster from

Hobby Components some time ago, it did not work at all.

It used a PIC18 but was of a different design to the one

on Ralf's site.) |

|

| There are

no components on the reverse side |

|

The

FAQ on the Hobby Components support forum advises that the

programmer "is not a general purpose JTAG programmer and

will only program Altera devices in the supported list".

This may help explain why so many of the USB Blasters are

advertised as being JTAG compatible without being swamped with

returns (maybe they are?); perhaps they are capable of being

used with other, non-Altera devices to the purchaser's

satisfaction or the buyers are only using ASP and don't

encounter the JTAG issue?

The other solution known to work is the

Waveshare

USB Blaster V2. These devices are available from Amazon but

in the UK cost around £35 - about 3x the price of the Hobby

Components version. This device uses hardware much closer to the

original Altera device, i.e., a FT245 (USB interface), a CPLD

(an Altera EPM3064A) and a 244 (LVC244A) buffer/line driver.

It seems probable that the reason the

very cheap clones don't support JTAG is the use of simple

resistors, rather then proper level shifters/buffers, on the

outputs. Another possibility is that the clock speed is too high

for the Altera JTAG interface that's supposed to run relatively

slowly (6Mhz). Either way, it doesn't really matter, the

important thing is knowing which ones actually work.

Initial Results

Despite my confidence that the Cyclone IV

FPGA board would work well, initial results were somewhat

disappointing. Whereas the emulated VDP output from the Cyclone

II board produced a crisp, clean, signal on my VGA monitor,

output from the Cyclone IV board produced noticeable "hum bars"

reminiscent of the legacy VDP monitor output. Results appeared

to depend on the VGA monitor being used though, Martin observed

similar results to me using his LCD display while Bill could

barely detect a difference with his LCD monitor and saw no

adverse effects at all with his analogue VGA monitor.

Although this was not a major problem, I

felt any loss of display quality was a step backwards and needed

to be addressed.

A number of theories were discussed that

might explain the issue, including inadequate I/O decoupling,

power supply effects and VRAM access timing.

Although the FPGA board has very few

decoupling capacitors on the I/O lines, there are no loess than

on the Cyclone II board and the Altera Cyclone IV Design

Guidelines (AN592) advises that "Cyclone IV devices include

on-die decoupling capacitors to provide high-frequency

decoupling. These low-inductance capacitors suppress power noise

for excellent signal integrity performance and reduce the number

of external PCB decoupling capacitors, saving board space,

reducing cost, and greatly simplifying the PCB design." Martin

also tried tacking on some additional capacitors which had no

effect on the display quality.

Another thought was the rate at which the

VRAM signals were changing and potential signal slew issues.

There was limited ability to change the signal transition

behavior on the Cyclone IV; the slew rate on LVCMOS pins cannot

be changed from the default. In an attempt to confirm that it

was a VRAM (rather than VGA) signal issue, Martin created a test

build that used internal FPGA RAM, rather than the external

VRAM, as the video data buffer which resulted in the VGA output

being more like that of the Cyclone II board's quality.

However, this could not provide the

final solution as, despite its increased RAM over the EP2C5

(having13kB), the EP4CE6 (with 30kB) does not have enough

available RAM to cater for the expanded video modes created by

Bill (a total of 36kB were required). This left two options,

either drop the enhanced video modes (another retrograde step),

or consider upgrading the FPGA to a higher spec Cyclone IV.

The next model up in the Cyclone IV range

(the EP4CE10) is available in the same pin-out as the EP4CE6 and

includes 46kB of RAM. So, another set of FPGA boards were

ordered with the higher spec FPGA.

Second

Attempt

When getting a set of boards made with

the EP4CE10 fitted, I also used a right angled connector for the

programming header. Not having the programming header on the MFX

board was a conscious decision when the board was designed. It is

not an issue for users, but does make it somewhat awkward to

reprogram the FPGA during development.

The JLCPCB

representation of the assembled board.

Sticking

with the Memotech Red theme, see how the programming

header now extends to the side of the board. |

|

Updated

board back from JLCPCB with an EP4CE10 fitted

Unfortunately, I did not check the clearance between the

right angled header and the SD card slot header on the

MFX PCB and

found when the boards arrived, that it would still not be

possible to reprogram the board in situ - oops! |

|

The good news is that that that board

works well, with all of the required memory now available inside

the FPGA. The change is almost cost neutral; although the larger

FPGA is more expensive, the external VRAM and socket can be

omitted. Getting these boards produced myself will end up a

little more expensive that using the cheap Cyclone II boards,

but the quality and reliability makes the small increase in cost

acceptable (to me anyway).

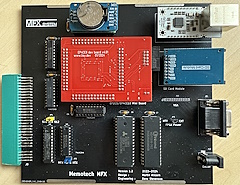

Form

over Function?

As I mentioned earlier, I thought that

the red FPGA boards would look really cool on a black MFX main

board, so I had a small batch made to check it out . . . .

The bare PCB.

With the ambient light at the time and the

reflections, it's not a great photo, but it's hopefully

good enough to show how nice the black PCB is.

As

an aside, Martin noted how much more difficult it is to

trace the track routing with the copper obscured by the

black mask, but that's not really an issue once the

design has been proven. |

|

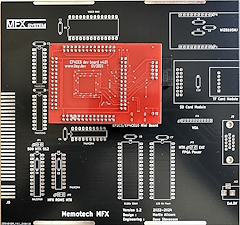

A mock up of

how the final board would look - one of the EP4CE10

modules placed on the PCB.

Do you think that it

looks as good as I do ? |

|

| Fully

populated with MFX components - note the unpolulated

VRAM socket as the external VRAM is no longer required. |

|

I think that the black PCB with red FPGA

board looks great and matches the colour scheme that Memotech

used for the MTX, it's almost a shame that MFX is hidden inside

the case! In terms of features though, the Cyclone IV version

currently doesn't offer much beyond what the Cyclone II version

delivers, other than perhaps some additional expansion potential. However,

we have been unable to think of anything that can easily be

added to the current design, so, if you have any ideas, let us

know . . . . .

Expansion Potential ?

With the MFX VRAM chip no longer being

required, the 25 FPGA I/O pins connected to the VRAM socket are

freed up and available for other purposes. There was a brief

discussion on the Memotech forum on possible uses for the

additional I/O and logic resources, some suggestions were :-

- Z80 DART emulation to facilitate adding RS232

connectivity

- Floating Point Accelerator (as in REMEMORizer)

- Additional monitor support to allow simultaneous VDP and

80 column card output

- Direct Memory Access (DMA) between the SD card and the

Z80

- Upgraded sound output

- A to D / D to A interfaces

- Digital I/O (GPIO) chip

- Real Time Clock (RTC) chip with battery back up

The majority of these ideas would require changes to the MFX

PCB but using the connections to the VRAM socket there are some

possibilities, albeit that, since there are no level shifters on

these connections, anything connected to the VRAM socket pins

needs to use the 3.3VDC levels used by the FPGA.

The simplest, and potentially most useful, modification is

probably a Real Time Clock. Martin had bought some 3v RTC

modules based on the DS3231 and made a small adapter board to

connect it to the VRAM socket. He modified the FPGA code to

support the RTC and added USER commands to the MFX ROM to

facilitate its operation from MFX BASIC.

Having the RTC opens up other possibilities, including the

option for Bill to enhance his FATCOPY program to include

time-stamps when creating files on the FAT partition. Going

further, if CP/M 3 was ported to MFX, file time stamps would be

possible on the CP/M side too.

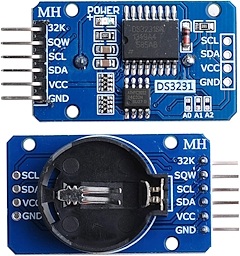

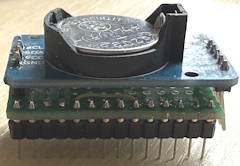

The RTC

module shown here is widely available from many sellers

with quite a few different product labels such as MH,

ZS042, SPX, etc. but the design is the same.

The

main components are a DS3231 RTC and a AT24C32 EEPROM

chip. The modules are typically advertised as being

suitable for 3.3V or 5V operation.

They may be

supplied with a CR2032 non-rechargeable coin cell, a

LIR2032 chargeable cell, or no cell at all. |

|

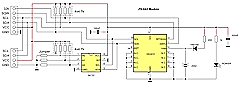

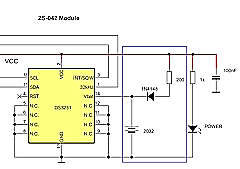

| The

schematic for the RTC module is shown here. |

|

| However,

there is a fundamental flaw in the design of the simple

"charging" circuit. The battery is connected to the

supply voltage through a diode and a resistor, feeding a

slightly reduced supply voltage to the cell - this is a

really bad idea when using a non-rechargeable battery |

|

Some modules are

supplied with a LIR2032 rechargeable cell, but that is

not a solution to the problem. Using a 5V supply, even

allowing for the presence of the diode, the charging

voltage is slightly too high for the LIR2032. With a 3V

supply, the charging voltage is much too low. So,

there's little point in using the more expensive

rechargeable cell and the best course of action is to

break the connection between Vcc and the cell and use a

CR2032.

The easiest way to prevent feeding Vcc to

the cell is to remove the resistor or diode in the Vcc

line to the cell - the components shown at the upper

right of the photo above. |

| |

|

| To connect

the RTC module to the VRAM socket, I made a "bodge

board" out of a scrap of prototyping board, only

connections to socket pins 28 (Vcc), 20 (GND), 3 (SCL)

and 4 (SDA) are required to be consistent with the FPGA

code. |

|

| RTC module

mounted on the "bodge board" |

|

RTC module

inserted in the VRAM socket

Whilst the bodge

board obviously worked, I wasn't very happy sending out

the otherwise "professional" looking MFX with one of

these to enable fitting of the RTC.

I decided to

get some "MFX I/O Adapter boards made. . . . . |

|

| Although

the RTC is the only expansion curently available for

MFX, I designed the I/O adapter to be able to handle

other options, should they become available. As well as

the hard wired connections to Vcc, GND, SCL and SDA used

by the RTC, the board provides connections to the other

VRAM socket pins and includes a prototyping area. |

|

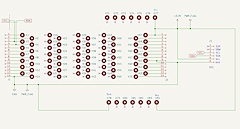

KiCad PCB

view

The PCB design, showing the pin connections,

is here |

|

| KiCad

render of how the board would look |

|

Obviously,

the adapter board needed to be black too :-)

The

completed board, ready to accept an RTC module |

|

| With RTC

Module fitted |

|

Profile

view.

I am definitely much happier sending these

out with MFX ! |

|

|