I wanted to put the MAGROM inside the

case of my MTX500, but as it already had Andy's MTX Memory Card,

a few modifications were needed to accomplish this. Dave had

already managed to connect the memory card with the CFX ( http://primrosebank.net/computers/mtx/projects/cfx/cfx_special.htm )

so this paved the way for my modification.

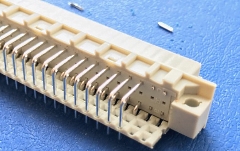

As with Dave's modification, I used the

same 2 row, 64 pin DIN 41612 connectors, which he very kindly

shipped over to me as I had trouble locating them over here in

the US.

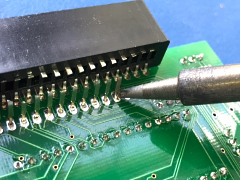

The first

task is to remove the right hand edge connector of the

memory board. I cut just on the right angle which leaves

enough of the metal pin behind for removal.

This

was repeated along the first row. |

|

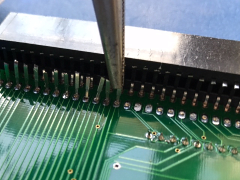

| Cutting as

close to the edge connector as possible, I removed the

remaining bits of metal. This makes accessing the pin

using long nose pliers a lot easier. |

|

This is my

new soldering station - a Hakko FX-888D.

I

cannot recommend it enough. It has transformed my

soldering skills immensely. No more horrible looking

"blobs". |

|

| To remove

the pin, I heated the solder joint until it melted and

gently removed it using the long nose pliers. |

|

As one

hand was holding the camera, I can't show the soldering

iron melting the solder at the same time the pin was

removed. You get the idea.

This was repeated

for the remaining cut pins. |

|

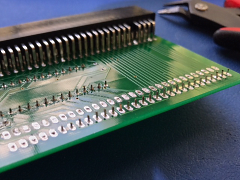

| The second

row was a bit tricky to cut, but I was able to twist the

edge connector up slightly to allow me to cut the pins

as close to the connector as possible. |

|

| Connector

removed. I started cutting the pins too close to the

board which made them a bit tricky to remove before I

twisted the connector as shown here. |

|

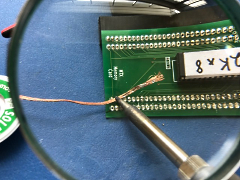

| My Rolson

Helping Hand makes extracting the pins a breeze as it

keeps the memory card steady and the magnifying glass

allows me to see what I'm doing! |

|

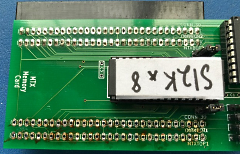

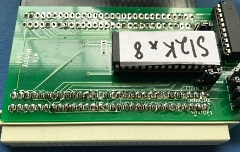

All pins

removed.

Next job was to clean up the solder

holes so that the new connector pins can be installed. |

|

| I placed a

small bead of flux on each of the filled holes as it

helps in the removal of the excess solder. |

|

Using a

solder wick, I went over each hole in turn.

The

wick acts like a sponge soaking up the excess solder and

clearing the hole |

|

| With all

the solder removed, the board was almost ready for the

new connector, but the burnt flux had to be removed

first using isopropyl alcohol, available from most good

chemists. |

|

Looking

good!

(Ed. Good as new in fact -well done David) |

|

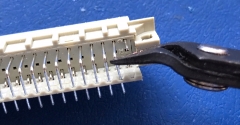

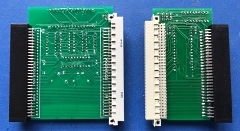

| The 64 pin

DIN connector has 4 extra pins that need to be removed

and after checking, double checking and triple checking

that the right ones were selected, they were cut off. |

|

| All four

pins removed. |

|

| This

procedure was mirrored for the other connector, once

again, checking , double checking and triple checking

the correct ones were selected as I didn't have spares

if a mistake was made. |

|

| Four pins

removed from the other connector. |

|

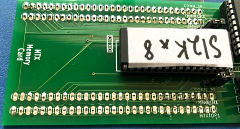

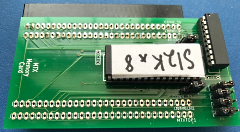

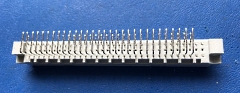

New

connector soldered into place. |

|

As with

Dave's modification, three patches R0 to R2 had to be

soldered between the edge connectors.

Also,

during testing it was found that another patch between

pins 30, the GROM, was also required. |

|

| The second

edge connector soldered into place onto the MAGROM. |

|

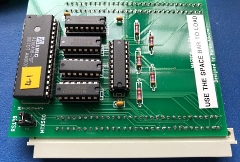

| Underside

of the two boards. |

|

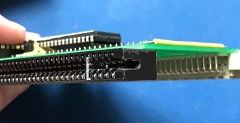

| Connected

together....... |

|

It's worth

noting that the edge connector needs slots cut out from

each end to make it fit over the board on the inside.

(Ed. with the slots cut, it is important that

the slot key in position 5 is present to prevent

misalignment when fitting the board !) |

|

| ...... and

fitted neatly inside the MTX500. |

|

| Up and

running! |

|