|

|

|

|

|

The Memotech MTX Series |

|

Martin Allcorn's Games ROM

|

|

|

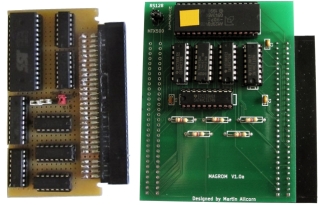

Prototype |

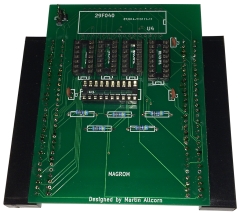

The finished product (V1.0) |

Building

MAGROM

As you can see in the photos above, Martin built the

"development" versions of MAGROM on prototyping board. This is

obviously a viable option for anyone who wants to build their

own, but as a number of other Memotech users seemed to be

interested in having one, I thought it would be worthwhile

getting some PCBs professionally made. Having never done this

before, this also seemed an ideal opportunity to develop the

skills that I would need to complete my

MTXPlus project.

To that end, with Martin's help, I have created a board

design using

KiCAD.

To give maximum flexibility, I wanted the option of being

able to fit MAGROM to either the internal or external MTX bus

connectors, in a similar way that Andy has done with his

MTX Memory Card. To support this, Martin modified the

operation of MAGROM to allow it to be bypassed, or rather, to

require it to be selected for use when resetting the MTX - this allows the board

to be left connected when not being used, even when mounted

externally, this feature will save wear & tear on the edge

connector - they are not meant for frequent connect/disconnect

operations.

As Andy points out, there is very little clearance between

the bottom of the MTX keyboard PCB and the surface of the

computer board and any expansion cards. Therefore, for the board

to be suitable for internal installation, the components need to

be placed as far up the board, towards the rear of the case, as

possible.

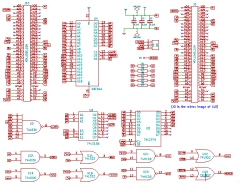

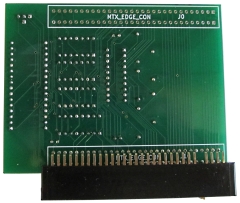

| I modified Martin's KiCad schematic to include

the second edge connector. Note, although shown on

the schematic in the same orientation, the J0

(internal) connector is the mirror image of the J10

(external) connector.

(Click on the image to

open the PDF) |

|

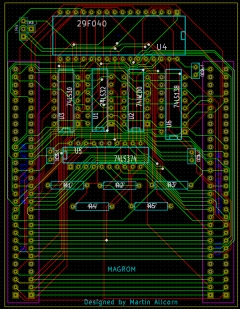

| Once we decided that the design was mature

enough, I took Martin's schematic and designed a PCB

for manufacture by

iteadstudio in China (they are the company that

Andy uses to manufacture his boards, including

REMEMOrizer). As

iteadstudio have a price point on PCB size at

10cm x 10cm, it made sense to try to keep the board

within these limits.

Combined with the limited space inside the MTX,

this means that the board layout is pretty congested

at the top, this was necessary to ensure that the

ICs were mounted in the deepest part of the MTX

case, i.e. at the rear. |

|

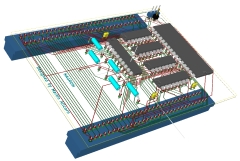

| KiCad 3D view of the PCB, with components

placed.

The edge connector profile is not accurate, but

you can see the the edge connectors are mounted on

the reverse side of the board. This is necessary for

the board to align with the MTX PCB as well as

allowing the components to fit sit in sockets, low

enough on the PCB to suit the height limitation of

the MTX case |

|

|

Although

this was my first attempt at committing a board

design for manufacture, I took the plunge and placed

an order with

iteadstudio on 6th February.

I was

resigned to having to wait a few weeks for delivery,

but they processed the order and shipped it very

quickly - the boards shipped on the 11th and arrived

in Aberdeen on the 19th, less than 2 weeks - more

than acceptable. |

|

| The boards looked great - at least they did

before I set to work with a soldering iron!

Visually, they appeared to be perfect and having

done a point-to-point continuity check against the

schematic, I felt confident enough to start

construction. In this photos, you can see that I

have mounted all of the passive components, apart

from the ROM socket as I was waiting for one to be

delivered. I forgot that the MTX PCB internal edge

connector does not have cut outs adjacent to the

pins like the external one, so I needed to cut

slots in the ends of the J0 connector - this would

have been done more easily before I fitted

the connectors! |

|

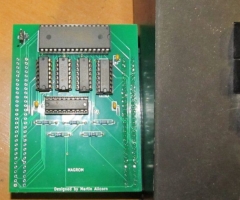

| While I was waiting for the socket to arrive,

Martin was able to press ahead and assemble his

board, shown here connected to the external

cartridge port, ready to go. |

|

| A higher resolution picture of the Martin's

finished board - with a single edge connector

fitted. If you display the full size photo, you

can see that, apart from the flash chip, Martin has

used 74HCT chips throughout. |

|

| The solder side of Martin's finished

board. His soldering skills are ever so slightly

better than mine ! |

|

| It works! Martin's board running Software

Version 1.0 - the photo records the time & date of

this momentous event :-) |

|

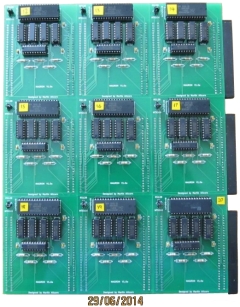

| MAGROM proved to be very popular and the initial

run of boards was soon snapped up. Although there is

probably not a huge demand for additional boards, we

have done a second run - shown here freshly

assembled by Martin.

They are functionally the same as the first run,

but I took the opportunity to add identification

labels to the machine selection jumper in the top

left corner.

(Do you want one ?) |

|

|

Bill of Materials

These are indicative prices

- for example, the ICs are based on prices from

RS Components

for tubes of 25, but they provide a good "ball-park"

figure. |

|

Passive Components |

| C1 |

100nF |

£ tbc |

| C2 |

100nF |

£ tbc |

| C3 |

100nF |

£ tbc |

| R1 |

4.7k 5% or 1% 250mW (¼W)

or 0.6W metal film |

£ tbc |

| R2 |

4.7k 5% or 1% 250mW (¼W)

or 0.6W metal film |

£ tbc |

| R3 |

4.7k 5% or 1% 250mW (¼W)

or 0.6W metal film |

£ tbc |

| R4 |

4.7k 5% or 1% 250mW (¼W)

or 0.6W metal film |

£ tbc |

| R5 |

4.7k 5% or 1% 250mW (¼W)

or 0.6W metal film |

£ tbc |

| P3 |

1 way 0.1" pin header |

£ tbc |

| P4 |

3 way 0.1" pin header |

£ tbc |

| - |

0.1" jumper shunt (link)

(for P3/P4) |

£ tbc |

| J0 |

Edge connector, 30x2 way

right angled type |

£ tbc |

| J10 |

Edge connector, 30x2 way

right angled type |

£ tbc |

|

Passives Total |

£ tbc |

| RS Prices - HCT |

RS Prices - LS |

| U1 |

74HCT32 |

£ tbc |

U1 |

74LS32 |

£ tbc |

| U2 |

74HCT00 |

£ tbc |

U2 |

74LS00 |

£ tbs |

| U3 |

74HCT30 |

£ tbc |

U3 |

74LS30 |

£ tbc |

| U4 |

29F040 |

£ tbc |

U4 |

29F040 |

£ tbc |

| U5 |

74HCT374 |

£ tbc |

U5 |

74HCT374 (preferred) |

£ tbc |

| U6 |

74HCT138 |

£ tbc |

U6 |

74LS124 |

£ tbc |

|

Semiconductor Total |

£ tbc |

Semiconductor Total |

£ tbc |

|

Total (ex.VAT) |

£ tbc |

|

VAT |

£ tbc |

|

Grand Total |

£ tbc |

|

|

|