|

|

The Memotech MTX Series |

|

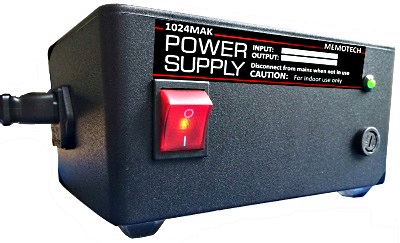

MTX PSU

Replacement

Background

The Memotech manuals do not give any details

on the MTX external power supply, the only "published"

information can be found on the label on the top of the PSU,

most PSUs that have been seen are marked

"Output 22.5 VAC 1A Tapped at 18V and 9V". The PSU

with Keith Clatworthy's low serial number MTX512 has additional information -

"Output 22.5 V ~ 1A. 18V ~ 0.82A. 9V ~ 0.28A.

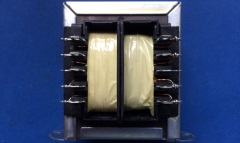

Inspection of the

PSU internals

confirms that the "PSU" is in fact only a

multi-tapped transformer, all voltage regulation & smoothing

is done on the MTX computer board, for a complete

description of the MTX power supply and voltage regulation

circuits, see my MTX PSU

page.

confirms that the "PSU" is in fact only a

multi-tapped transformer, all voltage regulation & smoothing

is done on the MTX computer board, for a complete

description of the MTX power supply and voltage regulation

circuits, see my MTX PSU

page.

Design

Since there are no "off-the-shelf" replacements

for the MTX PSU (transformer) available, until recently, a lost

or failed PSU would render an otherwise working MTX computer

inoperable. Mark Kinsey (1024MAK) has designed a modern

replacement for the MTX PSU, the design was first publised on

the

Memotech Forum. With Mark's permission and with

contributions from David Kimberlin Wyer - who has assembled a

110VAC version, design and construction of the replacement PSU

is described below.

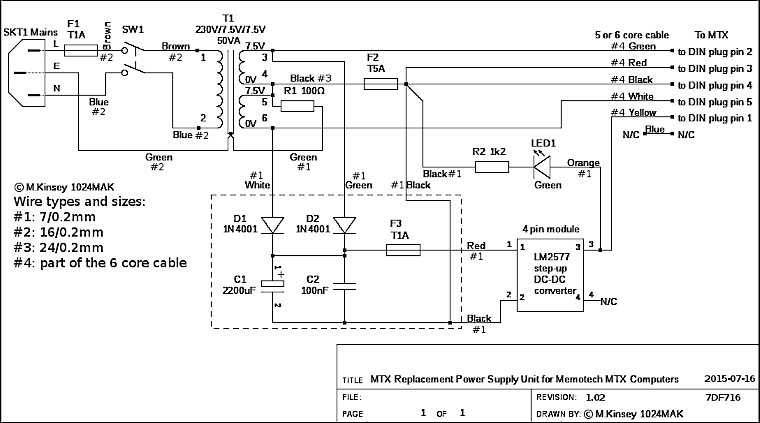

The secondary side of the transformer outputs 2 x 7.5VDC feeds

to diodes D1 and D2, used to supply the MTX +5VDC regulator and

the -5VDC zener diode.

A +16V DC supply is generated by an LM2577 based step up DC to

DC converter, which in turn is supplied by two diodes and a

2200uF 16V smoothing capacitor, which gets it's supply from the

two 7.5V AC feeds. This is fed to the MTX +12VDC regulator.

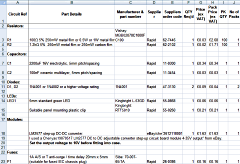

Mark has produced a parts list / Bill of Materials that is

mainly UK focused but provides enough information that would

allow alternative parts to be sourced in other locations if

required. David has produced a version of Mark's spreadsheet

that lists equivalent components and suppliers for readers in

the US. I have combined both lists into a single Excel

spreadsheet which is available for download in the Zip archive

at the bottom of this page.

Note : If building the 110VAC version, fuse F1 should be

replaced with a 2A time delay (slow-blow) fuse and F3 should

also be a time delay fuse (1A).

Construction

|

Mark's Original |

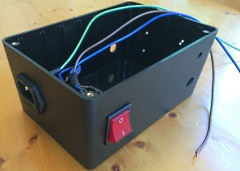

Mark designed the PSU to fit

into this multi-purpose ABS box, distributed by

Bradford

Consultants Limited, available in the UK from

Maplin.

This enclosure is

177x120x83mm, it is an ideal size but any similarly

sized ABS or metal box could be used.

Some

customisation is required to mount the power inlet,

outlet, switch and indicator. |

|

Preparing the plastic case.

Tools [Mark] used: fixed metal rule, tool

with a sharp point (for marking), battery drill, metal

HSS drill bits or wood drill bits (they have to be

sharp), needle files, various shape and sizes, somewhere

to work where you don't get told off for making a hell

of a mess.

As with all these, measure twice! Mark

once. Very carefully line up the drill (set to a slow

speed), double check that you are drilling INSIDE the

marked line, and carefully drill each hole |

Cutting the hole

for the IEC mains connector

Once you

have an outline, angle the drill slightly so that you

"join the dots" Then carefully file the excess plastic

away until you have a neat hole that is just large

enough for the connector. |

|

| Of course the last picture here

is a test fit! |

|

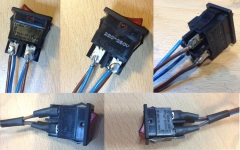

The mains switch is done the same way, but you have to

be a bit more careful, as this is a snap in type and too

big a hole would be a disaster!

Note : the drilling of all holes in the case

should be completed before the mains input and switch

are fitted permanently. |

|

|

Don't forget all the

other holes.

Go carefully as it is very

easy to cut too much, or too little and use a slow

speed.

Here I show how to do the holes for the

transformer fixing machine screws. Once you have drilled the holes

for the machine screws,

use a countersink drill bit (or similar).

Every

so often try putting the machine screw in the hole to

check if it fits nicely. The idea being that the head of

the screw is flush, or almost flush with the case. |

|

With most fuseholders, the hole they need is NOT

round. Instead it is round-ish with a flat side.

If you

just drill a round hole that it will fit in, it will

turn in the hole .

So drill an undersize hole, then get

to love filing, while trying the fuse holder every so

often until it fits through... |

|

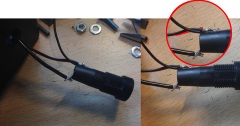

Before fitting items

to the case, it is far easier to connect some of the

wiring first.

Strip about 5 to 6mm of the

insulation, gently twist the wire strands together using

your fingers, then using round nose pliers form a "U"

loop. This will give the soldered connection added

mechanical strength.

Pass the stripped wire

through the hole on the terminal of the item and if

needed, flatten the "U" loop with smooth flat nosed

pliers. Cut off any excess wire strands, then solder.

Once the joint is cool, inspect it. If happy, cut a

suitable length of a suitable size heatshrink tubing.

Slide over the wire and terminal and using a hot air gun,

(I use a gas soldering iron with the hot air "tip")

shrink it down.

When shrinking it, keep slowly

moving the heat source, as if you try to just do one

section at a time, the heatshrink will wrinkle and/or

burn. I also use heatshrink tubing to keep the wires

together in tidy bundles. |

|

Soldering the mains switch |

|

|

Soldering the IEC connector |

|

|

IEC connector and switch done |

|

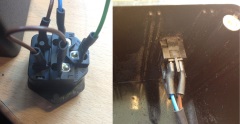

Don't forget to pass the wires through the fuseholder

insulation boot and the plastic nut before connecting

both ends of the wires.

Note:

The

terminal on the top of the fuse-holder (as viewed in the

photo) actually has three black wires and one red wire

connected to it. As you can see from the photo, at first

glance, it looks like only two black wires. If you look

a little closer, the red wire is hiding behind one of

the black wires as highlighted in the touched up insert. |

|

|

You can see the various stages of making the LED and

the associated resistor connections. Using small round

nose pliers, form the leads into a small coil. Note the

resistor leads are far easier to make into a coil. This

makes the connection more robust and easier to solder.

Cut off any lead that sticks out the end of the coil,

then over with heatshrink sleeving. |

|

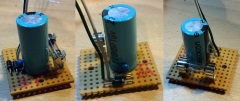

Building the DC board

| Components |

|

| |

|

| Diodes |

Two 1N4001 or 1N4002 or a higher voltage

rating |

| |

|

| Capacitors |

100nF ceramic multilayer type, 5mm spacing.

(the small blue bead) |

| |

2200uF 16V electrolytic (the large blue can) |

| |

|

| Fuse |

PCB fuse clips, 5mm pins, suitable for a

20mm type fuse.

1A "Fast" (F) or "Quick

Blow" (QB) 20mm x 5mm glass fuse |

|

|

|

|

|

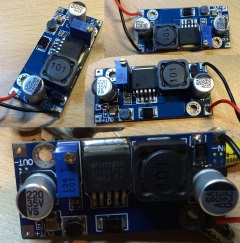

Step up DC to DC converter

LM2577 DC to DC Adjustable Converter Step-up Circuit

Board Module

[Mark] used a Chenyao19870517

LM2577 DC to DC adjustable converter step-up circuit

board module 4-35V output" from eBay UK at £1.95.

Set the output voltage to 16V before fitting into

the case. |

|

|

Assembly photos at various stages of the build |

|

|

|

|

|

|

|

|

|

|

Wiring the transformer earth connection |

|

|

Internal view of the 5A fuseholder and LED fixed to the

case |

|

|

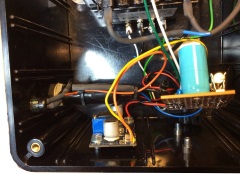

External view of the finished switch, LED and

fuseholder. |

|

|

External view of the finished IEC power input connector |

|

|

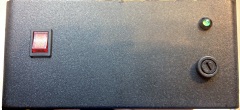

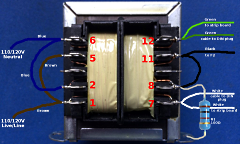

David's US (110VAC) Version |

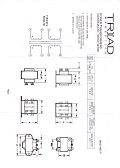

On Mark's

recommendation, David used a

Triad Magnetics VPS16-2700 (Digi-Key

Part Number 237-1261-ND).

Mark commented :

"Wire the primary 115V windings in parallel (see the

datasheet from the Digi-Key web site) and the secondary

windings in series, but use one of the connections used

to join the two secondary windings as the centre tap."

Mark also provided comprehensive instructions

for wiring the transformer for the US.

"Before

wiring up the transformer, measure the resistance (Ohms,

200 ohm range) of each of the primary windings. So the

first winding is between the connections labelled 1 and

2. The second winding is between the connections

labeled 5 and 6. The resistance should be about the

same." |

|

|

| Mark also

created this helpful sketch to show how to connect the

transformer for the US and provided the specific

instructions below : |

|

Note, connect the

wiring to the tag provided (this not shown in the

picture for clarity) by gently twisting the stripped

copper strands, threading through the hole, and then

bending the wire back to form a "U" or hook shape. This

improves the mechanical strength of the connection. Once

soldered, cover with heatshrink

The resistor

connects to the casing of the transformer at one of the

mounting holes by using a "solder tag". Also not shown,

at the same point where the resistor connects to the

transformer case, a green (or green/yellow) earth wire

should be connected, again by using a "solder tag".

Ensure that the transformer case where these "solder

tags" are connected is clean and free of any varnish or

other non-conductive protective coating by scrapping at

the metal with a screwdriver. We need a really good

connection.

Put the machine screw through the

case, put the transformer over it, then put the two

solder tags (with the resistor and the green wire

already attached) on the screw, then add a washer and

finally the nut. Once you have the mains wiring finished

and the fuse fitted in the IEC connector, measure the

resistance between the Live/Line (L) and the Neutral(N)

connections at the mains plug, or the IEC connections.

It should be about half of the value you got for one

winding that you took earlier. |

| David's

case with IEC connector and mains switch installed. |

|

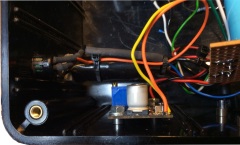

| Internal

view of the IEC connectors and mains switch |

|

|

Transformer, fuseholder and power indicator installed |

|

All done !

- Ready for power on and testing |

|

Close up of

David's fully assembled unit . . . . .

Just

missing a nice label :-)

- One possible

label design is shown below - other suggestions welcome. |

|

Testing

completed . . . .

Connected to an MTX computer . . . . . . . .

It actually works ! |

|

Testing

Arrange the stripped

ends of your output cable such that there is no danger

of shorting anything out. For example, use a small screw

terminal block (2A, 3A or 5A rating is fine). Or use a

breadboard.

Before connecting to the mains, it

is strongly recommended that you screw the lid on. Being

safe is a wise thing to do.

Before powering up,

connect you meter between the black and red wires, test

on the 200 ohms range and confirm that you get a result

of less than 2 ohms.

Next, connect each of your

meter leads to each of the 7.5V AC outputs (wire colours

green and white wires). Then power up. The meter should

display a AC voltage of 16V AC or more. If this okay,

that's the first test passed.

Next test each

7.5V AC output in turn (green, then white wires) to the

red, then the black wires.

Now to test the 16V

DC output, connect the meter between the yellow and

black wires. Confirm that you have 16V DC AND the

polarity is correct (yellow positive). Before

disconnecting the meter, switch to the AC range (better

still, if your meter has a mV AC range). Check that you

get a low reading. (This will vary between meters and

meter ranges.)

|

Test Results

from Mark's 240VAC model

Test and set-up

of LM2577 based step up DC to DC converter:-

LM2577

based step up DC to DC converter

Test input 8.01V at

19.7mA. Output (no load) 16.015V

| Unit constructed, test data:- |

| DIN |

Wire |

Output |

No load |

| Pin. |

Colour |

Name |

Voltage |

| 1 |

Yellow |

+16V DC |

16.025VDC, 6mV ripple (meter) |

| 2 |

Green |

7.5VH AC |

8.93VAC |

| 3 |

Red |

0V |

- |

| 4 |

Black |

0V |

- |

| 5 |

White |

7.5VL AC |

8.92VAC |

Internal DC supply (feeds LM2577 module):- 11.45V

DC, 33mV ripple (no load).

| Unit constructed, test load

data:- |

| DIN |

Wire |

Output |

Lamp |

Current |

Voltage |

| Pin. |

Colour |

Name |

|

|

|

| 1 |

Yellow |

+16V DC |

2 x 24V, 5W |

360mA |

15.785VDC, 28.2mV ripple (meter) |

| 2 |

Green |

7.5VH AC |

1 x 12V, 21W |

1.37A |

8.15VAC |

| 3 |

Red |

0V |

- |

- |

- |

| 4 |

Black |

0V |

- |

- |

- |

| 5 |

White |

7.5VL AC |

1 x 12V, 21W |

1.38A |

8.18VAC |

|

Test Results

from David's 110VAC model

| Unit constructed, test data:- |

| DIN |

Wire |

Output |

No load |

| Pin. |

Colour |

Name |

Voltage |

| 1 |

Yellow |

+16V DC |

16.02VDC |

| 2 |

Green |

7.5VH AC |

9.6VAC |

| 3 |

Red |

0V |

- |

| 4 |

Black |

0V |

- |

| 5 |

White |

7.5VL AC |

9.6VAC |

|

|

Parts list, Datasheets, etc. |

Replacement

MTX Power Supply Unit Parts list (V1-02 UK and V1-01 US)

Click on the image to download the Zip file

containing Mark's original parts list, along with

David's list of parts used to build a US (110VAC)

version.

(The speadsheet includes hyperlinks to

sources for the components on the 'net) |

|

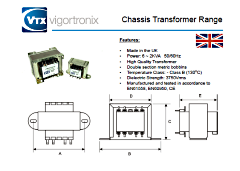

Datasheet

for Mark's transformer - a Vigortronix: VTX-126-050-2075

(Rapid

Electronics Order Code 88-3928)

Specifications : 230V 50VA 7.5V+7.5V

Update 27/03/23:

The transformer that Mark

used has been discontinued, but other similarly rated

units are suitable. A slightly lower power, but

acceptable option is an

Indel TS 40/020 available from

tme.eu |

|

Datasheet

for David's transformer - a

Triad Magnetics VPS16-2700 (Digi-Key

Part Number 237-1261-ND).

Specifications :

115V/230V 43VA 8V+8V |

|

Suggested label designs for the 240V and 115V versions.

Alternative suggestions are welcomed, possible

changes include swapping the positions of the "1024MAK"

and "MEMOTECH" texts - comments? |

|

|

|