|

|

The Memotech MTX Series |

|

PAL14L4 Reader for the

Memotech MTX

Given that there are 14 inputs, there are "only"

16384 (2^14) possible input combinations to drive the four

possible outputs. Tony Brewer made a PAL14L4 Reader

and wrote the Z80 code to control it. It takes just

over 10 seconds @ 4MHz to step through all of the

possible input combinations and read the 16K nibbles

of output, search for active low outputs, remove

redundancy and give the logic expressions as a text

string, e.g. XX X010 000X 1111

With Tony's help, I have drawn up a schematic for

the PAL reader interfaced to the MTX User I/O Port

using

KiCAD.

| Despite a few limitations, KiCAD allows you to take

a design all the way from a schematic through to the finished

PCB.

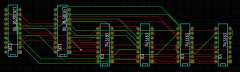

Using the KiCAD design suite, including the

on-line automatic "router", can produce finished

designs such as this board for the PAL Reader. |

|

However, it is uneconomic to have a board professionally made

just for a single unit, so an alternative solution for

the production of a working prototype was called for.

Stripboard

is a widely used type of prototyping board, and ideally, I would

have liked to have used a stripboard add-in for KiCAD.

Unfortunately, I could not find a free add-in that would have

done auto-routing of a KiCAD schematic, so I had to use a

stand-alone stripboard design program. I looked at a number of

free stripboard design tools including Stripboard Magic

(would not run on Windows 7), Stripboard Designer 1.0

(extremely basic), VeeCAD

Free (black and white only) and

VeroDes (written in VB5). Whilst it did look good, I was

originally put off by VeroDes by its requirement

to install a host of dependencies before the program would

install on Windows 7 and was intending to use VeeCAD Free,

being a bit reluctant to have VeroDes screw up my

Windows 7 machine. However, Tony had successfully used

VerDes and recommended it, so I installed it after all.

While I was having a go at designing the layout and routing

myself, Tony quickly came up with a VeroDes

design, which I have to say, is far batter than the attempt that

I would have made. Simple things (being easy when you know how)

like tying unused inputs and outputs together on chips having

these signals on opposite sides by not cutting the stripboard

between them saves cluttering the board with unnecessary links.

Having seen a photo of Tony's prototype board, I had bought

some stripboard (95 x127 mm) that I thought would have been more

than adequately sized, as it turned out, if it had not been for

Tony's compact design, I would have struggled to fit the parts

on my board without it becoming an untidy mess.

|

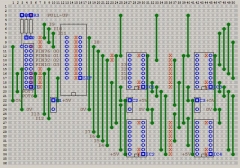

Tony's VeroDes design for the PAL

Reader. The green lines indicate the wire links on the

component side of the board and the red "X"s

denote breaks in the tracks on the solder side.

Normally, these are at holes, but for the IDC

connector, the break must be between the connector

pins and respective holes. VeroDes

is not able to show this accurately and breaks must

be shown aligned with the holes. (This prototype

uses the 5V supply from the MTX I/O port -

see below for why this

is not feasible and for the finished design.) |

|

|

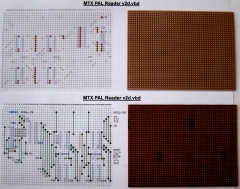

A really useful feature of VeroDes is

its ability to print overlays for the copper and

component sides of the strip-board, these can be

used to place the components and identify the track

breaks and wire links required. On the solder side

overlay, the position of the track breaks are

indicated by the red dots and the link ends or

component legs, by the grey circles. |

|

|

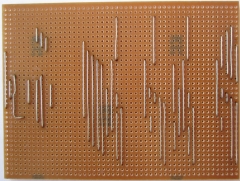

Preparing for the "operation", scalpel at the ready! -

The surgical mask and gown are just out of shot :-)

[If I do something like this again, I will

invest in one of those hands free solder stations

with a light and magnifying glass - it would have

been a great help - particularly when cutting the

tracks and checking the solder joints at the end.] |

|

|

The first task was to make the required cuts in the

tracks. You can buy track cutters for stripboard,

most of these are basically just a drill bit in a handle

that is turned on a hole to cut the narrow strips of

copper on either side of the hole.

(These tools are not suitable for cutting the

strips between holes.) |

|

|

When making the track breaks it's wise to "measure

twice, cut once" !

I had intended to use the trimming knife just to

make the cuts that were positioned between the holes

and to use a drill bit to cut the rest. Using the

knife, two parallel cuts were made through the

copper layer and the copper picked off with the tip

of the knife.

Since the knife was working well, I used it to

make all of the cuts. Once all the cuts had been

made, I smoothed off the cut edges of the tracks and

used a multi-meter to make sure that there was no

continuity between the two sides of the cuts. |

|

|

When cutting the tracks, I obviously handled the

board a fair amount which, more than likely, had

transferred some "grime" onto the copper tracks.

Prior to soldering, I used a PCB eraser (a small

rubber block with a fine abrasive embedded) to clean up

the strips and gave the board a final wipe over with

isopropyl alcohol to ensure a clean surface for the

solder to adhere to. |

|

|

The first

"components" to be mounted were the wire links.

As well as identifying the positions of the

links by their x,y coordinates, the

VeroDes component overlay was very

useful for making up the links themselves.

Starting at the right hand side of the board, I

first made a 90o bend on one end of a

piece of link wire and laid the link on a copy of

the overlay to measure the required length, prior to

making the second 90o bend. The links

then had bends at the correct distances to

match the holes in the stripboard and could just be

dropped into place prior to soldering and cutting

off any excess length with a pair of small side

cutters. |

|

|

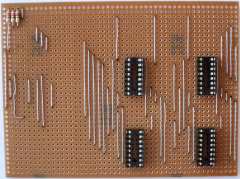

The resistors were installed next, followed by the

sockets for the counters. An observant reader may

have noticed that the resistor positions do not

match the schematic. The design was based on a plain

IDC header, as I had bought one with latches, to

allow for the extra length of the connector, the

resistors had to be relocated further up the board

and an additional cut was needed in the track

between the bottom of R2/R3 and the I9 input.

Similarly, the link from the header to the 0V

line had to be modified to clear the bottom of the

longer IDC connector, resulting in the "L" shaped

link. |

|

|

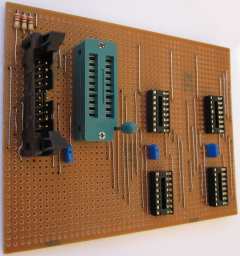

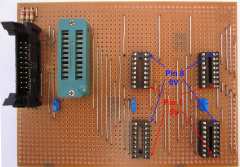

After the IDC header was installed, I found that it

was possible to get the 0V link to clear the bottom

of the connector by making a small radius curve at

the bottom end. This meant that the unsightly "L"

shaped link could be replaced with a vertical link

to match the others. The ZIF (Zero Insertion

Force) socket for the PAL has also been mounted at

this point, you can see that the locking lever is in

the open position. ZIF sockets should be soldered

with the contacts in the open position to reduce the

risk of soldering the contacts together when

installing it.

Self adhesive silicon rubber feet were then

attached to the solder side of the board to provide

a stable base and ensure the solder joints were

clear of the work surface. |

|

|

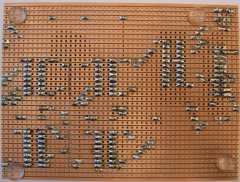

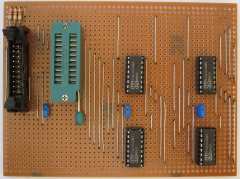

Solder side of the completed board, exposing my

(lack of) soldering skills! Prior to installing

the counters, the tracks were visually checked with

a magnifying glass to ensure that no solder joints

had overflowed onto adjacent tracks or across track

breaks and that any solder "splashes" had been

removed.

The board was also checked with a multi-meter to

ensure that there was continuity and no short

circuits between the lines shown on the schematic,

with particular attention being paid to ensuring

that there were no shorts between 0V and 5V. |

|

|

The board is wired to the MTX I/O port with 20 way

ribbon cable with an IDC plug on one end and a 20

pin DIP plug on the other. The cable should be as

short as possible, although I needed it to be ~12"

long to sit on top of my FDX just behind the MTX.

With the proper tool, crimping of the IDC plug is

quite easy, the DIP plug is a little more awkward,

but I found that a hexagonal pencil was just the

right size to fit between the legs to protect them

while crimping the plug. |

|

|

|

|

Installation & Testing |

|

|

|

|

The User Port interface is the blue 20 pin DIP

socket located at position 8C on the main board.

When installing the DIP header into the I/O socket,

pin 1 of the cable, identified with the red-stripe,

must be installed in pin 1 of the DIP socket. NB:

The User Port socket is installed the opposite way

around to all of the ICs on the board - pin 1 is the

connection on the upper right hand side of the

socket - on the ICs, it is at the lower left. |

|

|

The ribbon cable connected to the I/O port and

exiting the case above the printer interface

connector. I found that the DIP plug did not make

a very secure connection to the I/O socket and taped

the ribbon cable to the flat on the cut-out above

the printer port. |

|

|

The board was initially connected to the MTX

(with the power OFF) with all of the sockets empty.

When the MTX was powered ON, a check was made to

ensure that 0V and 5V were

present on pins 8 and 16 of the 74LS163s and pins

10 and 20 of the ZIF socket. The 5V supply from the

MTX connected to pin 11 of the IDC header was also

checked. |

|

|

To verify

that the counters can be correctly controlled from

the MTX, the following code can be used and the

voltages on the

CLR

and CLK pins measured on any of the counters. The

expected voltages on the pins are shown in the

table.

XOR A

OUT 7,A

;POT7=0, POT6=0 [From BASIC,

OUT 7, 0]

LD A,40

OUT 7,A

;POT7=0, POT6=1 [From BASIC,

OUT 7, 64]

LD A,80

OUT 7,A

;POT7=1, POT6=0 [From BASIC,

OUT 7, 128]

LD A,C0

OUT 7,A

;POT7=1, POT6=1 [From BASIC,

OUT 7, 192] |

|

74LS163 Voltages |

| Pin 1 (CLR) |

Pin 2

(CLK) |

| |

|

| 0 |

0 |

| |

|

| 0 |

5 |

| |

|

| 5 |

0 |

| |

|

| 5 |

5 |

|

|

After verifying the

supply and counter control voltages, the MTX was

switched OFF and the counters were installed in the

sockets.

When the

MTX was switched back ON and the voltages rechecked

I ran into a problem, the supply

voltage had been pulled down to less than 1V.

According to the MTX manual, the

MTX is only capable of supplying a maximum

of 20mA from Port 7 and the counter datasheet states

the typical power dissipation is 93mW, i.e., 18.6mA

per counter. With 4 counters on the board, I thought

that the Port 7 5V supply was not going to be adequate for the

counters. |

|

|

An

external 5V supply was required, fortunately, I had

enough bits & pieces to hand to make a suitable

modification.

A two pin

header was added to allow connection of an external

5V supply and the 5V line from the MTX was

disconnected by breaking the track at position 3,10.

A new link was installed between 12,22 and 12,23

with an additional break at position 15,23.

The

modified VeroDes design is as shown. |

|

|

With the

external supply connected, the following code was

used to check that the counters

were incrementing as expected

XOR A

OUT 7, A

LD A, 80

OUT 7, A

LD C, 40

LD B, 0

LOOP: LD

A, 40

OUT 7, A

LD A, C0

OUT 7, A

DJNZ LOOP

DEC C

JR

NZ, LOOP |

|

Zero "A" |

|

Reset all POT bits (clears counters) |

|

POT7 |

|

CLR = 1, i.e., NOT clear |

| |

| |

| |

| |

| |

| |

| |

|

Counter incremented |

|

Repeat . . . . |

|

until . . . . |

|

All 16384 counts done |

|

|

|

|

|

If all of the tests are

successful, the PAL Reader is now ready for use

Return to the

main PAL Reader page for

info on using the tool |

|