|

|

The Memotech MTX Series |

|

MTX System Diagnostic Cartridge

Memotech SDC

The Memotech System Diagnostic Cartridge came about when

contributors to the Memotech Forum (Memorum)

were trying to assist a user diagnose the problems with his

faulty MTX computer. The system in question had the typical

symptoms of a "dead" MTX, i.e., a totally black screen

accompanied by a constant tone from the sound chip.

These symptoms have quite often been found to be due to a

faulty RAM chip, but pretty much any system board fault can

cause the same symptoms. The ROM boot code jumps pretty much

straight into the memory test, it should start testing the RAM

at 04000H within a dozen or so instructions from starting up.

Once that's done the top 16k is cleared and the paged ROMs are

tested for auto run. At that point the VDP and PSG are set up

and the sound ship is silenced. That's what makes the blank

screen and "tone" such a pain to diagnose. All you really know

is the system didn't get to the point where the VDP is set up.

Martin Allcorn created a RAM test ROM when we were designing

MTXPlus+, it is possible to

burn a diagnostic ROM and install it into an EPROM compatible

MTX but unfortunately, not all MTXs allow the ROMs to be swapped

out for EPROMs without reconfiguration of the computer board.

This was the case with the system in question which has a

Version 05 computer board fitted with TMS4764 mask ROMs which do

not have direct EPROM replacements. (See

this page for guidance on how to replace these mask ROM with

EPROMs.)

Initially suspecting the RAM, the user had already replaced

the original RAM chips and the address decoders but the fault

remained and suspicion was falling on the ROMs. With the

difficulty in replacing the on-board ROMs, Martin proposed a

design for a basic diagnostic board that could be plugged into

the MTX edge connector to test the system without having to

replace the onboard ROMs. The initial proposal was for an

external ROM board with a 32k EPROM containing all 3 OS ROMs and

a GAL for decoding, this idea was expanded to include the

facility to include the ability to select an alternative,

diagnostic ROM.

A 20 pin 16V8 GAL or CPLD has more than enough capacity to

allow for paging in 4 different ROM images from a 32k, 28 pin

EPROM or EEPROM. However EPROMs are a pain for development

because of the erase time. Electrically erasable memory is

easier to work with, and it turned out only 1 pin has to change

function when fitting a 32pin socket to use a 64K EEPROM like a

27E512 or a 128K flash like the 39SF010 as well as a 27C256.

Since the larger capacity device is going to be fitted, at

least for development, I decided to add some extra options. So

the board has 5 jumpers:

- One jumper deals with the pin that changes

function. On 32k EPROMs where it's the program enable pin

that needs to be pulled high and the larger capacity chips

where it's an address line and needs to connect to the

paging logic.

- One jumper decides whether the diagnostic ROM images are

available to be paged in, or if the normal ones are.

- The other 3 decide exactly what ROM images are active.

With the normal ROMs setting It would be one jumper for each

of the A, B and C ROMs to individually selected to replace

the on-board ones. With the diagnostic ROM setting the extra

space on the larger devices can be used to test the ROM

paging system from within the diagnostics. Testing with

WINcupl suggests that switching the 16 ROM images that would

fit in a 128k FLASH chip is doable without needing to move

to a larger GAL/CPLD.

The board does not require any RAM to be available;

programming a Z80 to run with ROM only isn't as complicated as

it might seem. There are enough registers available to make a

lot of tasks doable. With no RAM you can't:

- call subroutines

- push/pull temporary data

- use interrupts

But it is possible to work around these limitations. The test

ROM uses the IX and IY registers as a crude 2 level stack in the

absence of a memory stack. The CALL instruction is replaced by

one of 2 macros that assembles as

| LD IX, return ; |

or IY |

|

| JP subroutine |

|

|

| Return: |

|

|

Because the "JUMP" opcodes have the same conditional options

as "CALL" it's possible to code the equivalent of a conditional

call, though the code currently in the test ROM doesn't need to

use that. Subroutine returns is replaced by

There's a restriction that it's only possible to go 2 levels

deep, and the right "return" opcode has to be used. That needs a

little thought in preparing the code to make sure subroutines

called from subroutines use the "right" call/return macros.

Conditional return isn't possible though that can be dealt

with by having a conditional jump to the unconditional "return"

instead.

The Z80's alternate register set are awkward to use as

general registers as all 3 register pairs swap at the same time.

Making it hard to change just 1 register or register pair. I've

used more macro's instead to give 6 bytes of "RAM" accessible to

the A register. They generate the following code. The assembler

will take a number 0-5 and convert that to BCDEH or L. So that

the "RAM" address can be defined as equates.

| ; store macro |

|

|

| EXX |

|

|

| LD %1,A |

|

|

| EXX |

|

|

| |

|

|

| ;get macro |

|

|

| EXX |

|

|

| LD A,%1 |

|

|

| EXX |

|

|

Swapping the A register with it's alternate has no real

penalty and can come in handy. Basically the test ROM is written

as if it was an 8080 with a 2 level stack and 6 bytes of RAM.

Restricted yes. but not too restricted.

Martin designed and hand wired a prototype board and

demonstrated his results on the

Forum.

| |

| |

|

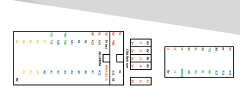

Martin does his prototype board layouts using Excel,

this helps him place the components on a matrix

representing his prototype board, but they are not

schematic diagrams in the usual sense.

Note: the layout is drawn as reference to be used for

soldering, so the view is from the underside of the

board, i.e., the components are a mirror image of the

normal footprints. |

|

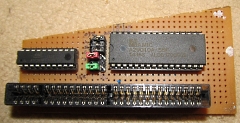

The board consists of two chips and some configuration

jumpers.

There's a 32k or larger (E)EPROM or

flash and a 16V8 GAL. I'm using a 128k Amic flash as

it's easier for re-programming. However changing the

bottom (green) jumper to the right hand setting would

allow a 28 pin 27C256 EPROM to be used instead. |

|

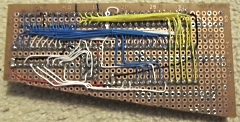

Solder side

of the board.

The board has been angled to march

the keyboard slope, the end plate won't fit with the

board in place, but that's not really an issue. If an

MTX is broken enough to need the board, the case will be

open anyway. |

|

Close up of

the test board in place

The empty socket in the

foreground is for one of the 74xx157 RAM multiplexers

(by default, these chips are not in sockets). With that

pulled booting the system on the standard ROMs will

produce the classic black screen and tone. |

|

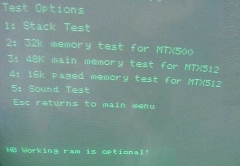

Booting from

the alternate boot ROM, even with the RAM disabled,

currently brings up this screen.

The RAM test

need some more work, possibly with an option to check

the ROM paging as well as the RAM. But the screen and

keyboard handling system is working. |

|

Booting BASIC

with no onboard ROM!

In this photo, you can see

that the three onboard ROM sockets are empty and the

system has booted to the "Ready" prompt from the ROM

images on the SDC.

(The RAM multiplexer has been

replaced and the onboard system RAM is working, only the

ROMs are being made available by the SDC.) |

|

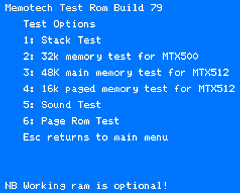

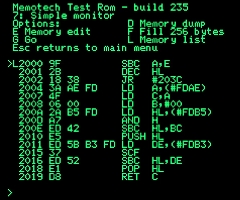

The ROM code

running under emulation to show the menu options more

clearly.

(As usual, if you click on the thumbnail

you can see the full size image) |

|

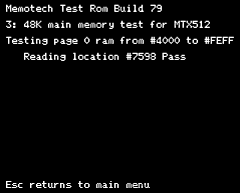

| Running the

Main Memory test (Option 3) |

|

ROM Build

Version 79

(The source file was written for

Martin's DIY assembler and may need manipulation to

build on other assemblers.) |

|

|

| Binary |

Source |

|

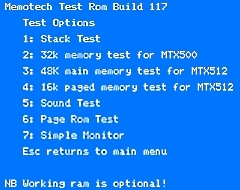

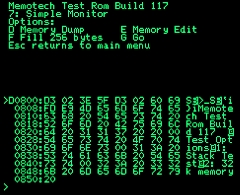

| An updated

version (Build 117) now includes a simple monitor

function . . . |

|

There's now

an option to run a monitor type facility to display and

write the RAM. As with the rest of the ROM, the dump,

edit and fill routines don't use any RAM themselves.

(An interesting issue with the keyboard reading code

was identified in this build. The keyboard scanning code

was executing much faster than in the standard MTX ROM

which was too fast for the pull-up resistors on the

keyboard sense lines, resulting in incorrect key presses

being detected.

This was corrected by adding a delay

loop to slow down successive OUT (5) instructions used

in the keyboard routines.) |

|

Now up to

Build 235.

The Test ROM now includes a full

disassembler as shown here

The board now also

includes a heartbeat LED to provide indication that the

CPU is running without requiring a working TV/Video

output. |

|

ROM Build

Version 235

The GAL file is the WinCUPL files for

the on board GAL |

|

| |

|

| |

|

| |

|

| |

|

| |

|

01/07/2019 -

Alternative Assembler Available

Until

recently, the source code for the firmware in our

Memotech hardware projects could only be assembled

without modification if Martin's assembler was used. The

assembler was written under BBC BASIC for RISCOS which

meant that very few people were in a position to

assemble the code themselves. Bill Brendling has

released a new Z80 assembler written in Python that

supports a number of formats, including Martin's

assembler format. Bill's program is available for

download here.

|

Current Status - April 2019

Martin's prototype board is the only one currently in

existence. Should you have need for such a board in the short

term, you might be able to persuade Martin to loan the board to

you - contact Martin through the

Forum.

Availability

Other than for a one-off use in fault-finding a broken MTX,

the board is not likely to be in much demand so there is

probably no justification for "productising" it. However, even

in its current form, it could be used to replace faulty mask

ROMs without having to modify the computer board, so, if there

is a demand, I will get some board manufactured and make

assembled units available for purchase, let me know if you are

interested and if there is sufficient demand, I will get it

done. A production board would likely need to have edge

connectors are both sides for ease of connection for initial

testing and permanent internal installation if required. The

cost is not likely to be significant, say, £10-£15, depending on

configuration.

There may be more demand/justification for a manufactured

board if it could be enhanced to provide RAM for a MTX where the

RAM has failed. This would be more difficult as, if it were not

removed and depending on the failure mode, the onboard RAM could

conflict with any replacement RAM on this board. This needs some

further thought . . . . .

|