I now had a working 512K 3a, a 3a with a faulty screen and

no main board, a bottom half of 256K 3a with a faulty main

board, and a top half with a broken hinge and a working

display. So I decided to use the failed upgrade main board

with the faulty screen and no main board, but that left the

problem of the faulty screen. That left the only option of

removing the LCD screen from the casing of the top half with

the broken hinge and swapping it for the faulty screen as

the case has the intact hinges.

|

Step |

Screen Disassembly |

|

1 |

I first

selected the case with the faulty screen and the

intact hinges. I then carefully peeled off the

screen bezel by using a small screwdriver in-between

the bezel and the backing, which is either the LCD

glass or the plastic holders on the side.

I ruined

the bezel by exerting too much pressure with the

screwdriver so it created a bulge in the thin

plastic or metal sheet - not sure which. Work

slowly, gently lifting the bezel as you go. |

|

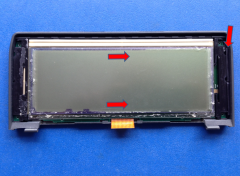

Once removed, a thin plastic spacer on the far right

needs to be removed by pushing downwards with a

small screwdriver as indicated by the arrow and

pulling it out.

Next, using your thumbs on the LCD panel, push it to

the right into the area vacated by the plastic

spacer. It should be loose enough now to fall out of

the casing. |

|

|

2 |

Rear of the LCD panel. |

|

|

3 |

Front of the LCD panel out of the casing. |

|

|

4 |

I then performed the operation

outlined in step 1 again, but on the top half with

the broken hinge and working display.

Once removed from the case, I then used a solvent

(WD40) on a cloth to remove the adhesive residue

from the LCD glass, the plastics surrounds, and from

the rear of the removed bezel. Use a plastic scraper

or thumbnail to remove the large deposits. |

| The cleaned up LCD panel was then inserted into

the case vacated by the faulty one, by placing it

off centre towards the right and sliding it

underneath the clips. I then placed the thin spacer

into the gap on the right and slotting it upwards to

lock it into place. |

|

|

5 |

Cleaned rear of the bezel. |

|

|

6 |

Front of the bezel. |

|

|

7 |

I then used a tube of Evo-Stick Impact adhesive

and smeared it on the rear of the bezel carefully

not to put too much on as I didn't want it seeping

out along the sides once I applied bonding pressure. |

|

|

8 |

I then re-assembled the rest of the

parts as described previously. I snipped off a few

legs of the IC's that I soldered as part of the

upgrade to make it work again as a 256K 3a. |

|

9 |

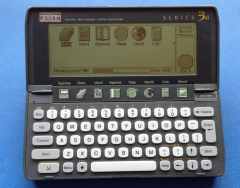

As good as new ! |

|

|

Those observant amongst you would have noticed that

the LCD screen not quite level, so make sure yours

is before you bond the bezel . |