|

|

The Memotech MTX Series |

|

Memotech Hardware Repairs

FDX Disassembly / Reassembly

Caution !

With the FDX open, and the rear panel swung

away from the end plates, the FDX power supply and the additional transformer

used to supply power to the MTX (if present) are revealed. These items have

exposed terminals which carry

mains voltages - take care when working

inside the FDX with the power on, also be aware that

the PSU capacitors can hold charge for a few seconds after the power is removed from

the system. The FDX is a nice looking unit, but was not made to be

"maintenance friendly" and does not have the modular

construction of a modern day PC. There are few, if any, internal

parts that can be tested or replaced without an almost complete

disassembly of the FDX. The notes here are based on

disassembly of my own FDX and photographs of others. Given

Memotech's penchant for "customisation", you may find that the

internals of your FDX are different from what you see here, but

they should be very similar.

Depending on the reason for opening up the FDX, you may, or

may not, want to test the system while it is in a state of

partial or even complete disassembly. It is more than likely

that you will though and you may want to connect and disconnect

the MTX keyboard at various times during the process. As you

will see later, once the FDX is even partially disassembled, it

can be difficult to get access to the interface connector on the

bottom of the case to connect or disconnect the ribbon cable. I

suggest that you leave the cable connected at the FDX and have

the MTX case open to expose the RS232/Bus Interface card and

make any connection or disconnection of the ribbon cable at the

MTX end as required. It is possible to connect the interface

cable onto the RS232/IF card with just the MTX right side end

plate off.

|

Disassembling the FDX |

| Power Off the FDX, and if using

a separate PSU for it, the MTX too. You can

always apply power later if required, but with

the exposed mains terminals and bits of bare

metalwork likely to be moving around, not to

mention your hands & fingers, this is an obvious

and essential safety step. |

| The FDX is held together is a

similar way to the MTX itself, with a number of

fixings, in this case "Phillips" head screws,

rather than hex-head used in the MTX, and

interlocking aluminium panels. The case is

made from two "U" shaped panels which form the

front and back, these are linked by flat plates,

forming the top and bottom and the case is

completed and held together by two flat end

plates secured with screws.

The front and back pieces have profiled

edges, one edge is a flat groove, the other, a

round channel like the front of the MTX case.

The flat edge can be pulled away from the edge

of its mating plate but the channel edge must be

slid all the away along its edge to separate it

from its mate, like the MTX keyboard.

As shown in this end on sketch, the front

panel has the round channel at the bottom and

the rear panel has it at the top. |

(not to scale)

|

| There are a multitude of fixings

in the base, I thought it might be useful to

do a sketch showing the position of the major

components and their fixings. It is useful to

know where things are positioned before you make a start on

opening the case. This is one of my FDXs, but

you may find that yours is different, there

seems to be a bit of variation on how some of

the components were fixed to the case. |

|

| With the FDX facing forwards,

remove the six Phillips screws from the left

hand end plate. The top panel can then be slid

out to the left, exposing the top of the 6" card

frame and the disk drive(s).

In this single drive model, you can see the

FDX PSU below and behind the silver plate where

the second floppy would sit in a twin disk

system. If the second disk was installed, you

would not be able to see the PSU at this point. |

|

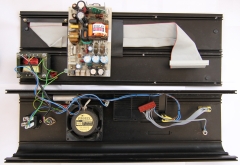

| Removal of the two Phillips

screws at the rear of the right hand side of the

case with allow the rear panel to be swung away

from the top of the case and lie flat on the fan

cover. Removal of the input and output power

leads will allow the panel to sit flat on the

bench. The edge of the rear panel fits into the

slot in the base panel, this is not profiled, so

can be pulled completely away from the base if

required.

At this point, the case body and rear panel

are linked by the power and earth wiring,

care is required to make sure that you don't

stress or break any of the interconnecting wires

as there is not much "slack" in the wiring. |

|

|

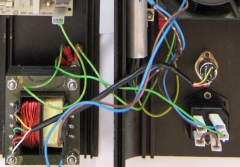

There is a small, 2-pin connector for the AC

input and an earth wire push-on connector that

connect the supply from the rear of the case to

the FDX PSU.

In the twin drive FDX, with an MTX power

transformer, the transformer will need to be

unbolted from the base to allow the parts to be

completely separated. Unless you are replacing

the transformer, this step should not be

required.

|

|

|

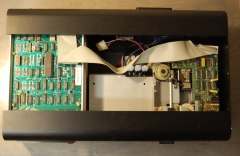

With care, it is now possible to access the

6" card cage and remove the PCBs as required.

and access the drive electronics. However,

further disassembly is required before the

floppy disks or FDX PSU can be removed. In the

unlikely event that you want to remove the 6"

card frame, with the PCBs removed, you can get

access to the fastenings which secure the card

frame. On my FDX, this is done using four bolts

that pass through the base plate and are secured

with

nylock nuts on the bottom edges of the card

frame.. |

|

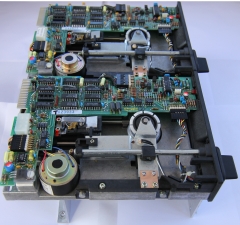

| A recurring theme on my FDX

pages seems to be the maintenance "unfriendly"

nature of the construction - the floppy drive

mounting arrangement is no different. Access to the

drives to allow

them to be removed is a real pain, the case

needs to be almost completely dismantled before

the drives can be released.

The floppy drives sit on an aluminium plinth

and are secured from underneath, there is no

real way of removing a drive from the plinth

while it is still in the case.

It **may** be possible if you

have a mirror, have appropriate tools and are a

bit of a contortionist, but as you need to work

in close proximity to the PSU, there is a good

chance that you would damage it, so the best way

is to remove the drive plinth from the case. |

|

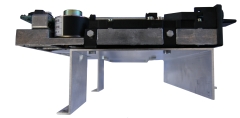

| A profile view of the plinth.

The two "feet" shown at the left hand side of

the photo straddle the PSU at the rear of the

case, each is fixed with a bolt through the case

bottom and secured with a

nylock nut. The front of the plinth is

supported by a ledge in the front panel and two smaller diameter bolts are

held captive in a channel in the front panel,

these bolts are also secured with

nylock nuts.

|

|

| This is a view of the underside

of the plinth. Each drive has four "L" shaped

brackets bolted to its sides, the bottom of the

brackets are tapped to mate with the bolts that

you can see on the underside of the plinth. |

|

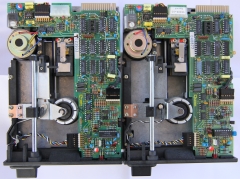

| In this overhead view, between

the two drives, you can see two of the bolts on

each drive that fix them to the angled brackets.

They were cunningly selected to be just too

long to allow them to be removed from above

without fouling on the opposite pair of bolts! |

|

Remove the right hand end-plate

and disconnect

the floppy power and data cables. Remove the two

bolts that pass through the base and remove the

nylock nuts that hold the plinth to the

front panel.

The front panel can be tilted forward

slightly, hinged on the round profile mated with

the base, to make removing the drives a little

easier.

By tilting up the drive plinth it is possible

to slide it to the right until it clears the

case. Care must be taken not to catch the wiring

to the power switch on the front panel , the

power wires to the card cage, or the low voltage

AC wires from the MTX transformer. You need to

be careful not to damage the main PSU or the MTX

transformer as you slide out the plinth. |

|

| |

|

Is it

probably not necessary to remove the front

panel, but if you want to do so, it is fairly

easy. The plastic trim is clipped into the cut

out on the front of the FDX. Working from the

front, slide you fingers behind the panel, in

front of the card cage. There are three plastic

clips on the top edge, working from the left,

gently push out each clip in turn until the top

edge clear the cut out. The bottom edge has a

groove in it. Lifting it slightly will allow it

to be removed. The easiest way to detach the

trim from the front panel is to put it back

inside the case, this can be done by angling it

as required. The front panel can now be slide

to the right until it clears the base plate |

|

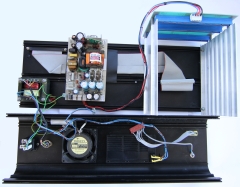

| Front view, showing the card

cage, the main FDX PSU and the MTX PSU. The

fan exhaust grill and power switch panel is

lying adjacent to the PSU and are still attached

to the AC input wiring on the rear of the case.

(If you want to completely separate the base and

rear panels, the MTX transformer can be removed

from the base.) |

|

|

There are probably few occasions where you will

want to remove the card cage, but it is easily

done. On my FDX, four bolts, secured with

nylock nuts, fix the card cage to the base

of the case. As you can see from the photo, it

is not necessary to remove the card cage in

order to remove the PSU. |

|

|

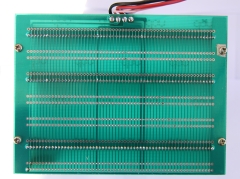

Rear view of the 6" card cage, showing the shadow

of the three PCB connectors fitted and the

available slots for additional PCBs - originally

intended for the Silicon Disk cards. When

viewed from this side, the connections from the

FDX PSU are, from left to right : Common

(black), +12VDC (pink), +5VDC (red) and -12VDC

(blue).

The rear of the card cage is positioned just

inside the front, left hand cover, behind the

fan exhaust grill and power switch panel. |

|

|

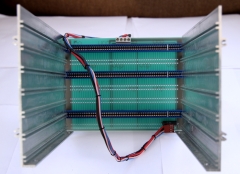

Front view of the card cage, showing the three

PCB connectors and the power lead to the FDX

PSU (unplugged). When

viewed from this side, the connections from the

FDX PSU are, from left to right : -12VDC (blue),

+5VDC (red), +12VDC (pink) and Common (black).

In the bottom right hand corner, there is a

large power resistor between +12VDC and ground,

I think this must be to make sure that the PSU

12VDC current is above the minimum shown in the

specifications. (Only 1 of my FDXs has

this.) |

|

|

On my FDX, the main power supply is fixed to the base with

two self-tapping screws that fit into the metal

channel close to the front edge of the base

plate (at the top of this photo) and two bolts fixed through the

base. Other FDXs I have seen use four bolts that

are fixed through the base plate rather then the

self-tapping screws. All fixings have insulating spacers

fitted and the bolts are secured with

nylock nuts. A protective earth wire is fixed to the

corner of the PSU with a push-on connector. |

|

|

The remaining component fixed to the base plate

is the transformer used to supply low voltage AC

to the MTX from a double drive FDX - it is not

fitted to the single drive version.. This is the

same transformer that is used in the MTX desktop

PSU, without any protective cover - the primary

and secondary winding taps are exposed - you

need to be aware of this if working on the FDX

under power. Similarly, the mains input and

connections to the fan may also have exposed

terminals. |

|

|

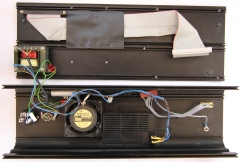

Stripped down to the (almost) bare minimum.

The only thing left, which should not usually

need to be disturbed, is the ribbon cable that

links the external connector to the SM1

Interface board in the card frame. The black

plastic sleeve provides additional insulation and

protection between the solder side of the PSU

PCB and the ribbon cable. |

|

|

Reassembly |

| Like all good instruction manuals

say . . . . . . |

Reassembly is just the reverse of

the above steps

(Award yourself extra points if you have some screws

left over! ) |

|