|

|

The Memotech MTX Series |

|

MTX PIC Programmer

This page describes the

PIC

Programmer that Bill Brendling

demonstrated at

Memofest 2013. Bill created this in the 1990s to help with

his other electronic projects, giving him the ability to

program PIC

devices using his MTX via the parallel port.

Bill produced his own PCB for the design, there are a number of

ways of doing this for the hobbyist, just

Google "pcb diy"

for more information.

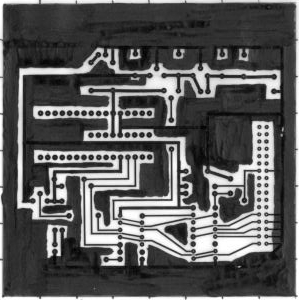

Briefly, one way of making a home-brew PCB starts with a board that is

completely copper clad, the track layout is "printed" onto the

copper board and forms a protective layer over the copper that is

to become the tracks. An etching solution, such as ferric

chloride, is then used to strip off the exposed

areas of copper, leaving the tracks in place, before finally, the holes

are drilled by hand.

Describing how the original PCB was produced, Bill recalls that

"the layout for the PCB was done with transfers

and was photo-etched.

|

Most

of the board area is blacked out, and so remains

copper. There are three reasons for that:

-

1. It saves on Ferric Chloride during the

etching.

-

2. It often gives better results, While trying

to etch away large areas of copper, the edges of

all the tracks are also being attacked, and

narrow tracks, such as between IC pins, can be

etched right through.

-

3. Having a large ground plane does not hurt

anyway. "

|

|

|

|

|

|

|

|

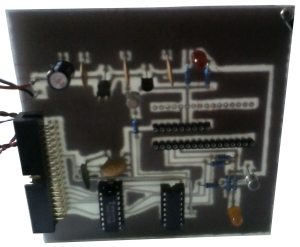

The base board is fibreglass and is

translucent, holding the board up to the light, the

areas where the copper has be removed can be clearly

seen. |

|

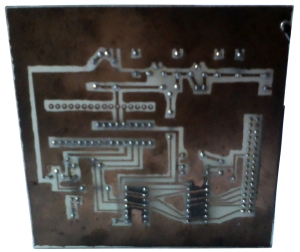

The rear of the board, showing the

tracks and bare copper areas more clearly |

The software to drive the programmer is available as a

Type 07 image

or a PC Zip

File

Bill has provided some notes on the original design . . . . .

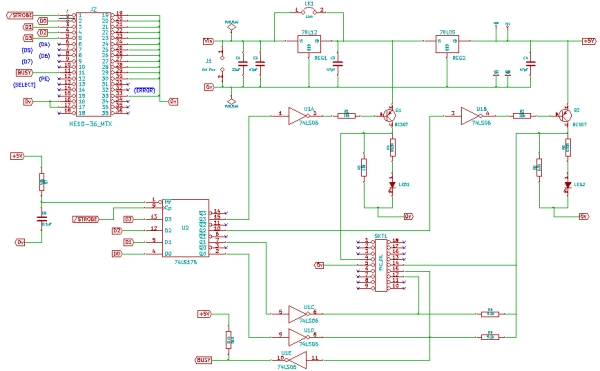

[The PIC programmer] "is the simpler circuit, as

the PIC chips I use so far (16c84 and 16f877) use a serial

programming algorithm. The four lower bits of the printer data

port are used to drive the programming:

My circuit uses the printer strobe line to latch

this data, which in hindsight is probably unnecessary.

The CP/M software (BLOWPIC hexfile) that drives

the programmer uses the Memotech CTC chip to time the

programming pulses. One word of caution: the programmer software

assumes the hex file format generated by my PICASM software,

which is not consistent with that produced by Microchip

MPASM or the open source

GPASM. The issue

was caused by lack of readily available information on the

format used at the time I developed the software. Since I now

use GPASM and GPSIM on Linux to develop PIC software, I will fix

that at some time, but have not yet got around to it."

"A couple of points to add to the circuit

description. It is important that the inverter chip used is the

variety with open collector output (or open drain in the HC

equivalent) for two reasons:

-

When the input of U1A is low, the output

will drift up to +12v.

-

When the input of U1D is low, the output is

high impedance, only pulled high by R9. This means that, in

this state, the PIC can readily drive the pin high or low

when outputting data, which is then fed back to the Memotech

via U1E and the printer BUSY line.

The cable I use to connect either of my

programmers to the Memotech is a ribbon cable, with IDC

connectors attached opposite ways around at the two ends (pin 1

at one end attached to pin 26 at the other). This has the

advantage of bringing the data lines onto the upper row of

contacts on the right angle connector, where they are easier to

connect to.

LNK1 is inserted if running the unit off a

regulated 12 volt supply, or removed if using an unregulated

supply of 15 volts or greater."

Bill has provided a

sketch of the original design. I have taken the sketch and

drawn a schematic using

KiCAD, note the KiCad schematic reorders the

pins on the interface connector for a straight through cable

between the MTX printer port and the programmer.

Click on the image to

open as a PDF

|